ENTRON Controls, LLC. • 700120S • Page 95

7.5 STEPPER RESET

7.5.1 MANUAL STEPPER RESET

1. Dial any schedule from schedule map for desired stepper. For example, in STEPPER mode

0101

0101

01 for stepper A, dial any schedule from 00 to 09; in STEPPER mode

0202

0202

02, dial any schedule.

2. Put the control in PROGRAM mode.

3. Press and hold the ENTER push button. While holding the ENTER push button, press both

DATA push buttons at the same time and hold momentarily. After this, LAST STEP

LL

LL

L.

SS

SS

S. and

LAST COUNT

LL

LL

L.

CC

CC

C. parameters will be initialized with appropriate values programmed for

first step; e.g., for stepper A, LAST STEP will now be

L.S.L.S.

L.S.L.S.

L.S.=

0000

0000

00, and LAST COUNT

L.C.L.C.

L.C.L.C.

L.C.=

03250325

03250325

0325.

The stepper will be reset only if all three push buttons are properly pressed. After reset, both

initialized parameters will be displayed on the SCHEDULE and DATA displays for a short

period of time. These two parameters may be reprogrammed by entering desired values and

pressing ENTER, at any time, without resetting stepper using all three push buttons.

4. Put the control back in OPERATE mode.

STEPPER RESET may be performed not only by holding ENTER and pressing both DATA

push buttons at the same time, but also by manual programming of LAST STEP

L.S.L.S.

L.S.L.S.

L.S. and

LAST COUNT

L.C.L.C.

L.C.L.C.

L.C. for corresponding stepper.

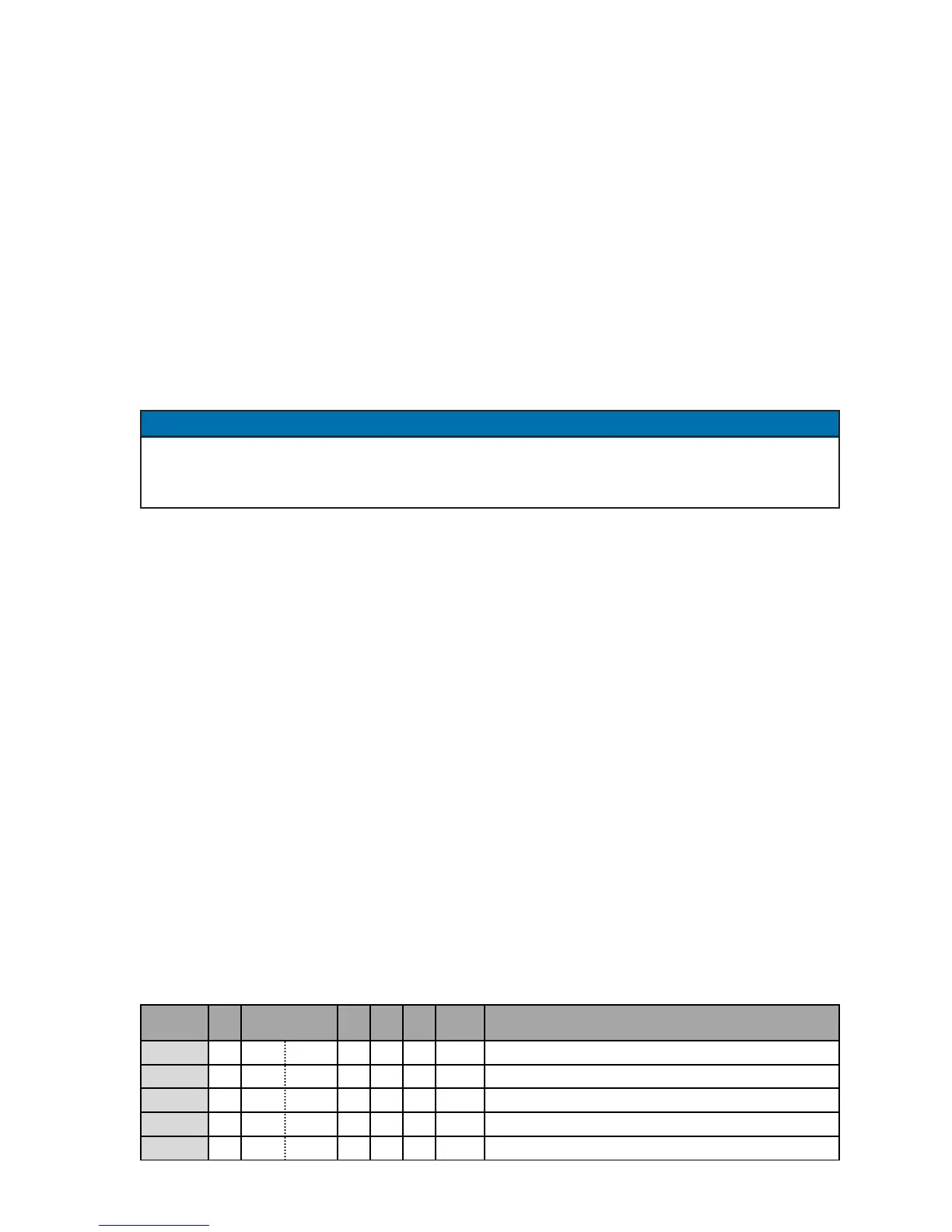

7.5.2 AUTOMATIC STEPPER RESET

When necessary, the stepper can be automatically reset by adding the RESET command using

an additional schedule after LAST STEP. The RESET command is simply an empty schedule –

no valves, no other parameters except for OFF time. If the stepper counter reaches zero on

LAST STEP, the control will read the next schedule. If it finds the RESET command, it will

reload the stepper automatically. Any new sequence will start again on the first step.

To enable automatic STEPPER RESET:

1. Display the next schedule after the last schedule from schedule map for desired stepper.

2. Put the control in PROGRAM mode.

3. Clear all parameters for that schedule. In PROGRAM mode, the delete shortcut may be

used by holding ENTER and pressing the PROGRAM/OPERATE push button.

4. Make sure that the WELD COUNT is 0000 for this step.

5. Program the OFF time to 99 cycles.

6. Put the control back in OPERATE mode.

If necessary, a warning signal may be added just before the RESET command. Simply add an

additional step with a very low WELD COUNT (for example 0010 welds). This schedule may

contain an additional valve output which may be used to warn the operator by means of light or

some other alarm device.

NOTICE

STEP COUNT

00

G!"

0325 01 Step 1

01

G!#

0400 01 Step 2

02

G!$

0450 01 Step 3

03

G!%

0010 03 Pre-warning step, adding Valve 2 output

04

G!&

0000 99 00

RESET command (all other parameters="")

VALVE

MODE DESCRIPTION

WELD STEPS

SCHEDULE

…

… OFF …

Loading...

Loading...