ENTRON Controls, LLC. • 700120S • Page 57

5.4.4 AUTOMATIC VOLTAGE COMPENSATION AND MONITORING –

C.C.C.C.

C.C.C.C.

C.C.

In addition to the original AUTOMATIC VOLTAGE COMPENSATION (AVC), an additional

series of settings are available in the EN1000 or EN1001 Controls with PROM firmware

version 619016-002A or later. The new settings allow voltage monitoring, or compensation and

monitoring.

To program AUTOMATIC VOLTAGE COMPENSATION (AVC) or VOLTAGE

MONITORING (AVM):

1. Put the control in PROGRAM mode.

2. Click SELECT until the DATA display shows

EFEF

EFEF

EF.

3. Click the left SCHEDULE push button until the SCHEDULE display shows

C.C.C.C.

C.C.C.C.

C.C.

4. Use the DATA push buttons and the tables below to program the desired values.

5. Press ENTER.

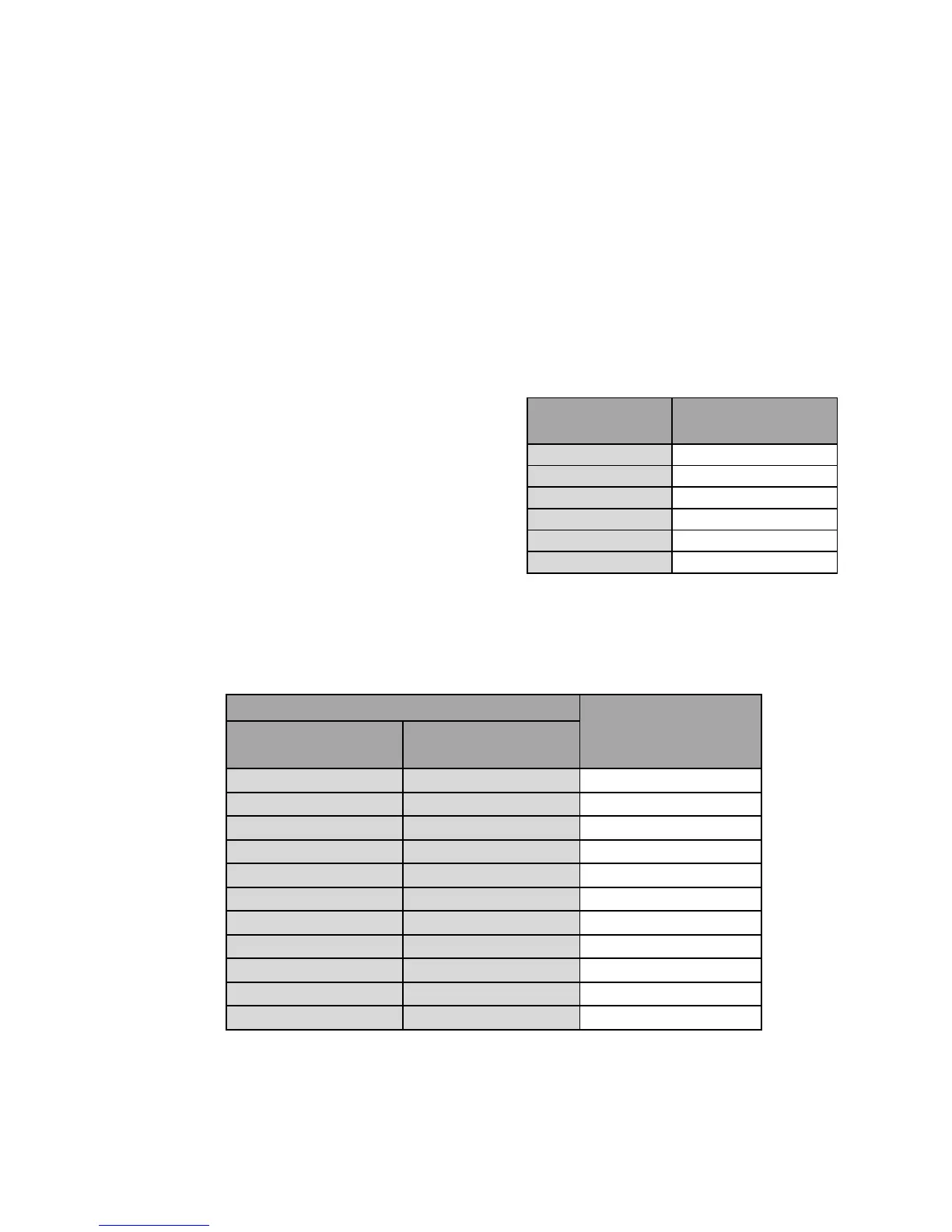

Original AVC settings are shown in Table 5-4.

These settings are available on all controls, but

they can be used only for compensation, not for

monitoring.

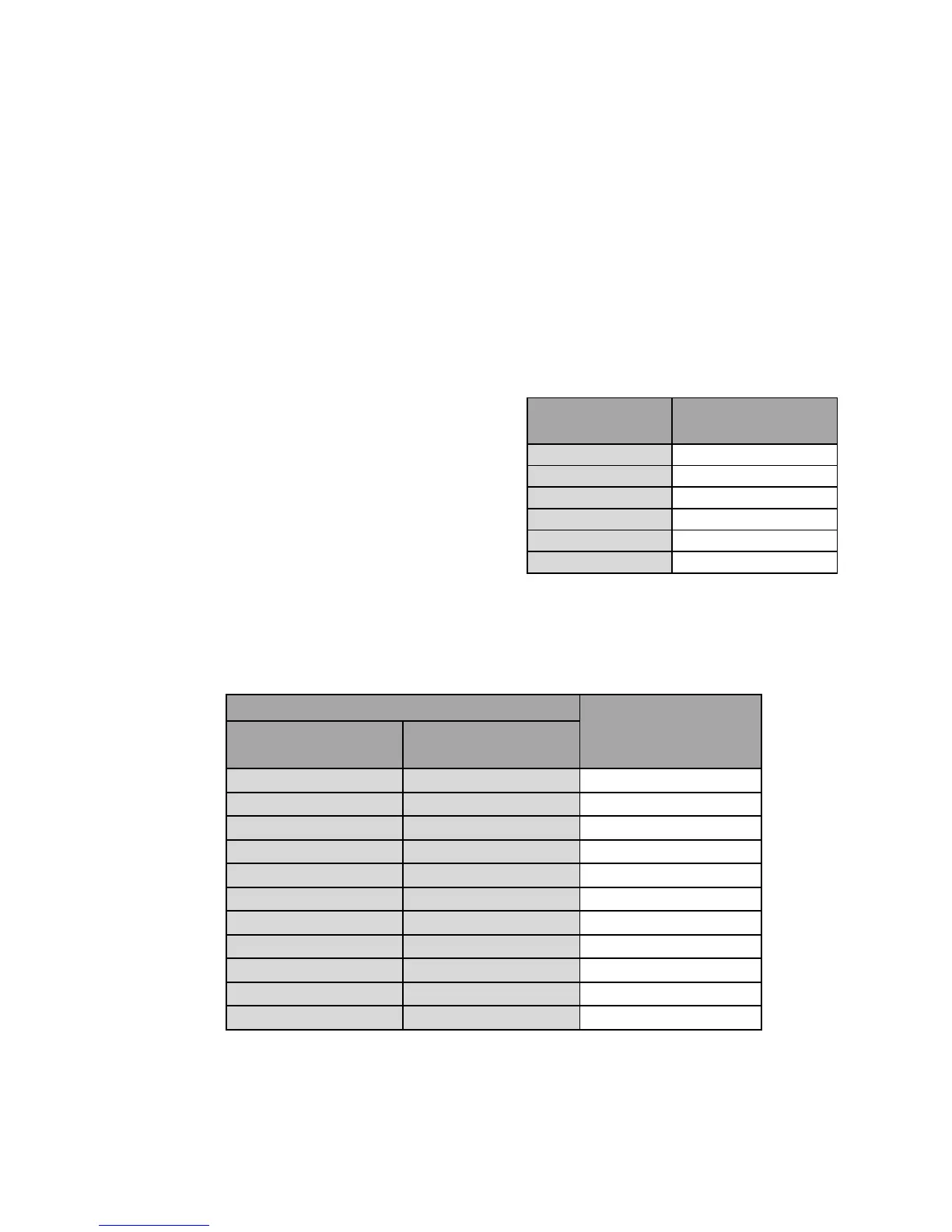

Additional AVC and AVM settings are shown in Table 5-5. These settings are available only on

controls with PROM firmware version 619016-002A or later.

Table 5-5. AVC parameter values

The AUTOMATIC VOLTAGE COMPENSATION uses a nominal set point value to determine

whether the line voltage is changing during idle periods (between welds). The AVC (

C.C.C.C.

C.C.C.C.

C.C.) values

must be set during a time in which the line voltage is at this nominal value. For example, if the

steady state line voltage is approximately 480 VAC, do not program

C.C.C.C.

C.C.C.C.

C.C. until the line voltage is

as close to 480 VAC as possible.

Table 5-4. Original AVC values

AVC parameter

Line Voltage

in VAC

00

AVC disabled

01 110

02 230

03 380

04 460

05 575

MONITORING &

COMPENSATION

MONITORING

ONLY

10 11 +/- 3%

12 13 +/- 5%

14 15 +/- 10%

16 17 +/- 15%

18 19 +/- 20%

20 21 +/- 25%

22 23 +/- 30%

24 25 +/- 35%

26 27 +/- 40%

28 29 +/- 45%

30 31 +/- 50%

THRESHOLD

AVC parameter

Loading...

Loading...