ENTRON Controls, LLC. • 700120S • Page 67

BEAT INITIATION DURING SQUEEZE AND WELD –

b.E.b.E.

b.E.b.E.

b.E.=

0202

0202

02

BEAT DURING SQUEEZE AND WELD is typically used for brazing applications. It provides

the same functions as provided by BEAT DURING SQUEEZE; in addition the weld sequence

can be terminated before WELD time has elapsed. If the operator opens the initiation during

WELD time, the WELD time is interrupted and the control immediately advances to HOLD

time. If the initiation switch remains closed, however, the control will weld normally until the

end of the programmed schedule.

This flexibility is required for brazing parts with differing characteristics that require different

weld times. The WELD time must be set for the longest time required to bring the parts to the

required brazing temperature.

To program for BEAT DURING SQUEEZE AND WELD:

1. Put the control in PROGRAM mode.

2. Use SELECT to find

EFEF

EFEF

EF.

3. Use the SCHEDULE push buttons to find

b.E.b.E.

b.E.b.E.

b.E.

4. Use the DATA push buttons and make

b.E.b.E.

b.E.b.E.

b.E.=

0202

0202

02.

5. Press ENTER.

b.E.b.E.

b.E.b.E.

b.E. MODE –

b.E.b.E.

b.E.b.E.

b.E.=

0303

0303

03 *

In this mode, control will have faster response time after Emergency Stop or power-up, without

redundant checking schedule data validity. It will eliminate all self-checking delays as well.

This mode was added in PROM firmware version 619016-002J. It does not affect initiation and

control will operate, after closing initiation, exactly the same as in default NON-BEAT mode

(

b.E.b.E.

b.E.b.E.

b.E.=

0000

0000

00), except that control will be ready for initiation much faster. Faster initialization after

closing Emergency Stop input may be very useful when light

curtain is used.

When

b.E.b.E.

b.E.b.E.

b.E. is set to

0303

0303

03, the control will run a faster internal

self-check after reset. This will reduce the time the control

requires to go from an Emergency Stop condition to a Ready

To Operate condition. This time will range from 30ms to

60ms maximum. To accomplish this reduced time, the

redundant schedule data checking has been removed in this

mode. The schedule data is still checked before use in a

schedule when the weld sequence is initiated. The main

reason for this addition is for machine control systems that

use the TS1-ES1 and TS1-GND terminals to disable the weld

control between initiations.

The standard recovery time of 200ms could add to machine

cycle time if

b.E.b.E.

b.E.b.E.

b.E. is not set to

0303

0303

03. Before PROM firmware

version 619016-002J, recovery time was around 500ms. This

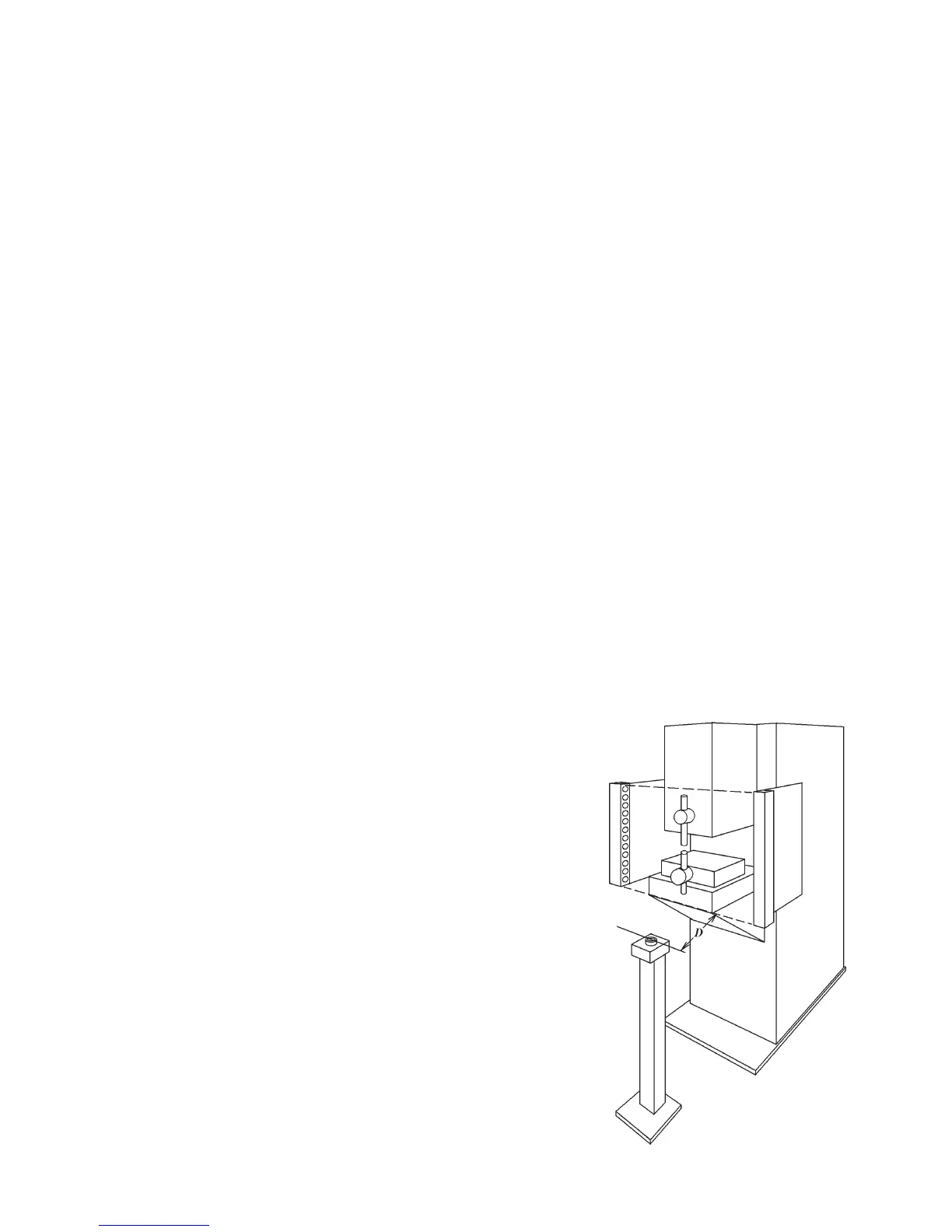

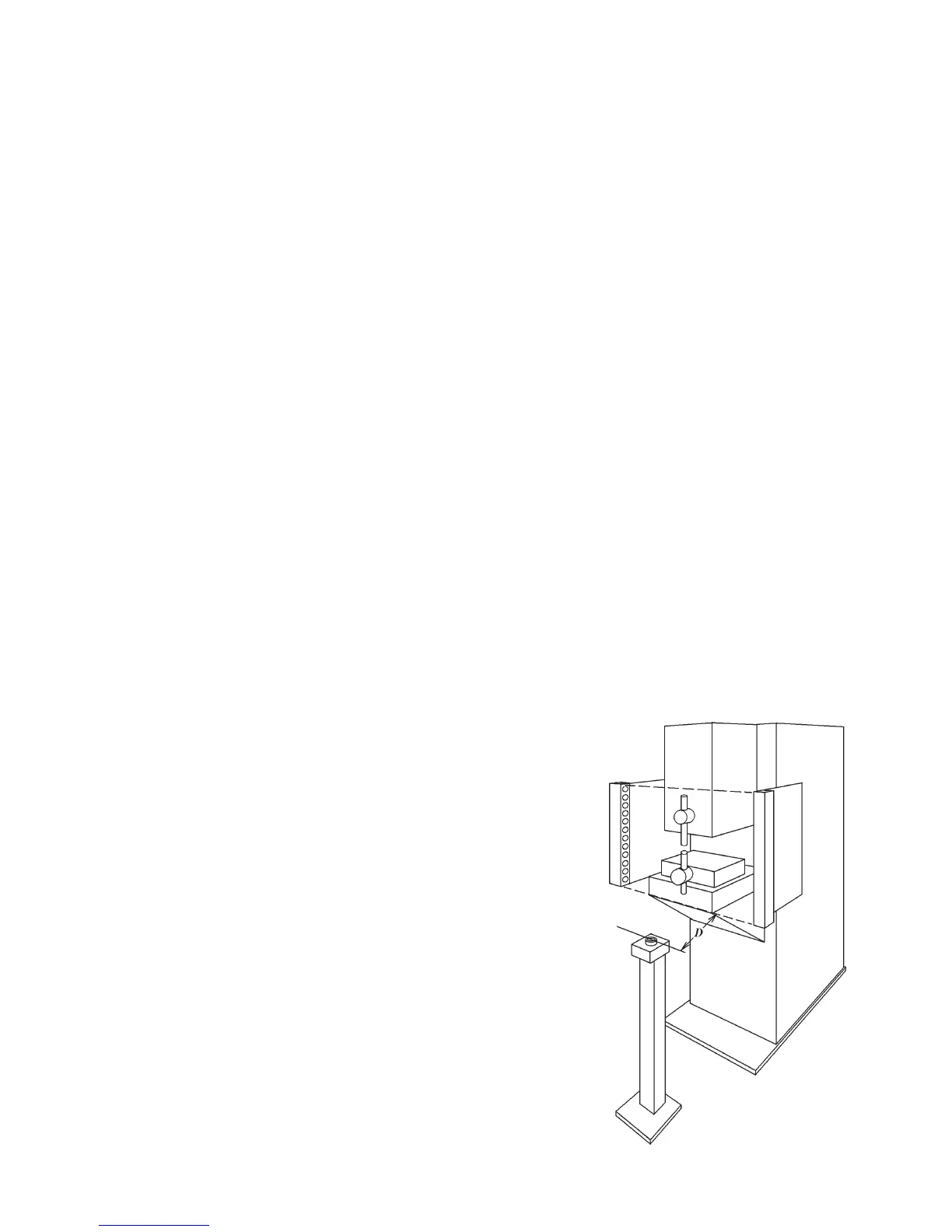

is especially apparent when light curtains, as shown in Figure

5-16, are used to activate the Emergency Stop circuit.

Figure 5-16. Using light curtain

5.4.8 BEAT OPERATION INITIATION MODES –

b.E.b.E.

b.E.b.E.

b.E. (cont.)

* This mode will not affect BEAT operation.

Loading...

Loading...