Page 38 • 700120S • ENTRON Controls, LLC.

4.6 NON-VOLATILE MEMORY ERROR

All ENTRON microprocessor based controls make extensive use of non-volatile memory devices

for parameter data storage. Although safety features (control relays and opto-isolation) are in

place to insure high voltage spikes do not appear on low voltage circuits, non-volatile memory

devices can sometimes be affected by improper hookup, electrical disturbances generated in

other equipment operating nearby, or in the welding machine itself.

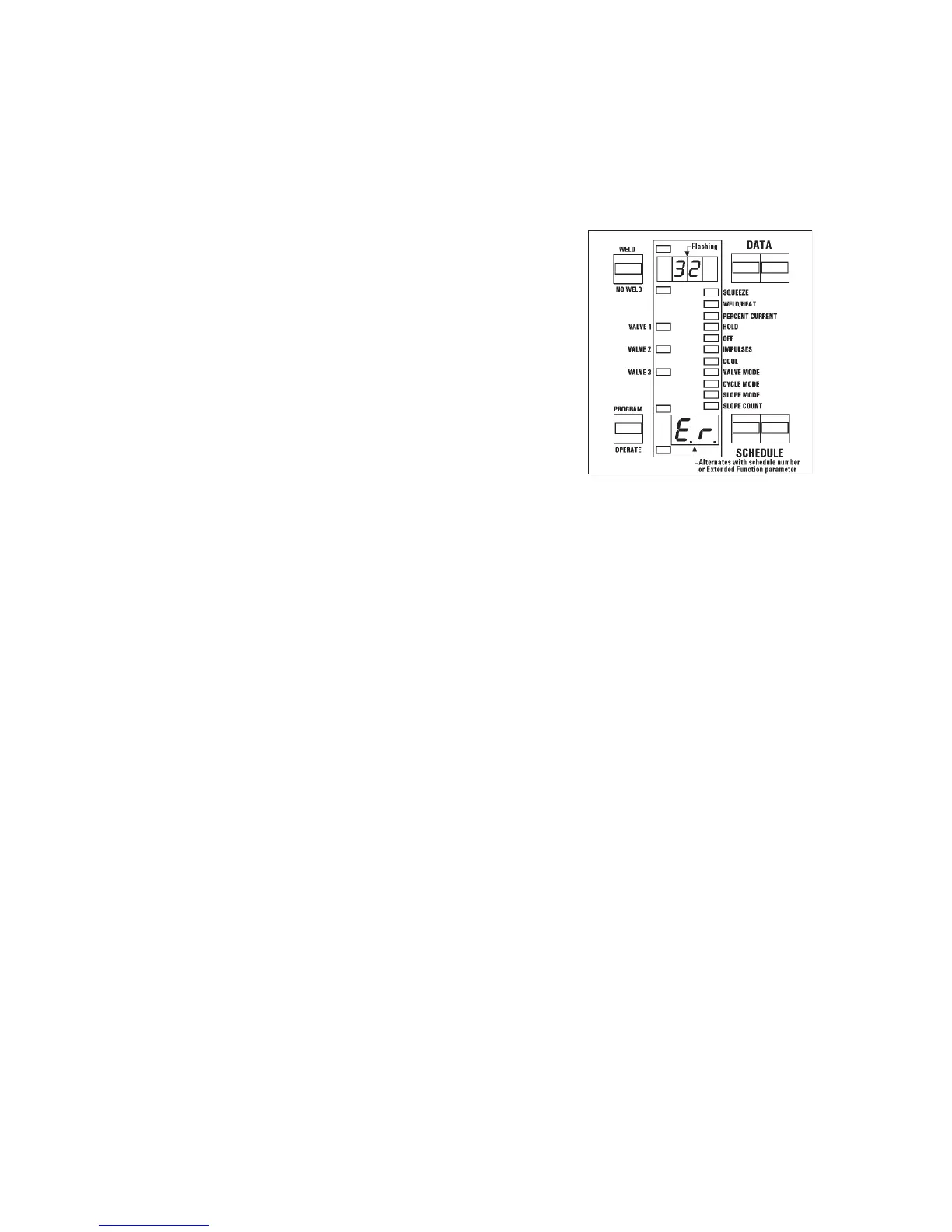

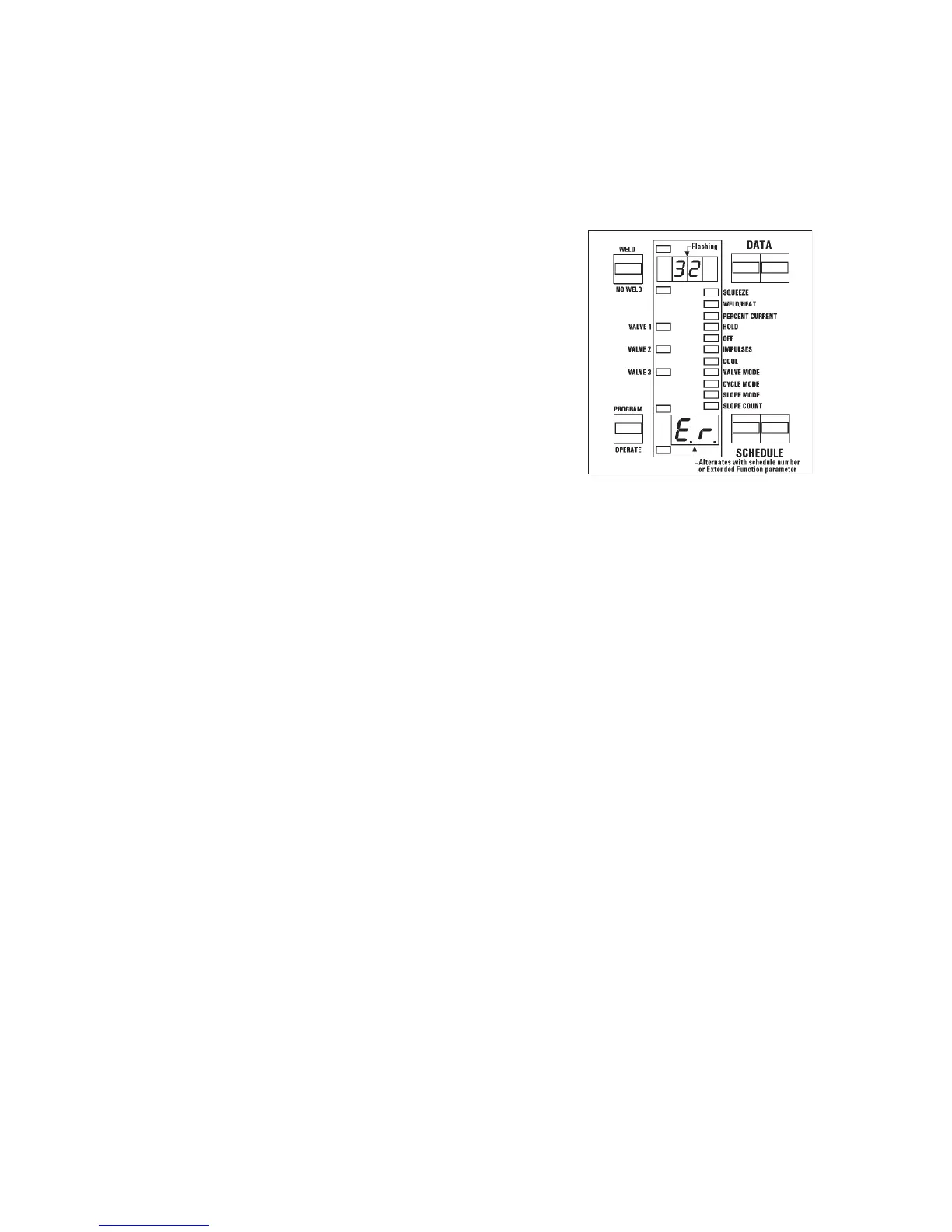

When an EN1000 or EN1001 Control is powered up or returns

from Emergency Stop condition, it executes a diagnostic test

that reads all memory locations within schedule storage areas.

If invalid data is stored in memory, control will display a flashing

3232

3232

32 in DATA display and

E.rE.r

E.rE.r

E.r

..

..

. in SCHEDULE display alternating

with schedule number where invalid data (error) is found. If

invalid data is found in EXTENDED FUNCTIONS’ memory

area,

E.rE.r

E.rE.r

E.r

..

..

. alternates with EXTENDED FUNCTION parameter

designation.

The ERROR

3232

3232

32 indication does not mean there has been damage

to welding control. It simply means something has caused invalid

data to be stored in one or more memory locations. The control

will not sequence until this error has been corrected.

To recover from this condition:

1. Press SELECT push button to stop flashing.

2. Place control in PROGRAM mode.

3. The operator can use SELECT to find function containing invalid data.

4. Use DATA push buttons to correct data.

5. Press ENTER.

6. Return control to OPERATE mode.

If more than one location has been affected, it may be necessary to use CLEAR ALL command

in EXTENDED FUNCTIONS to erase all memory locations and restore default settings (factory

settings).

Reoccurring ERROR

3232

3232

32 (ERROR

1414

1414

14 Flashing in previous revisions)

The effects of electrical disturbances can be minimized or prevented by observing the following

precautions when installing the welding control:

1. Make sure cabinet is properly grounded to power distribution system, nearby water

pipe or other effective building ground with a wire adequate for its application.

2. All wires connected to the pilot input terminals on the TS1 Terminal Strip (FS1, FS3,

FS7, FS11, PS1, ES1, NW1, TLS1, and their adjacent GND terminals) should be separated

as much as possible from other wires connecting to solenoid valves, welding transformers,

and the AC line. These pilot input wires should never be run through the same conduit

with solenoid, welding transformer and AC line wires. Connection of any GND terminal

to earth ground might cause ERROR

3232

3232

32 or even ERROR

1414

1414

14.

WRONG example for wiring and routing of low and high voltage wires in same conduit for

typical EN1000/EN1001 Series Controls is shown in Figure 4-10.

Figure 4-9.

Flashing

1414

1414

14 or

3232

3232

32 Errors

Loading...

Loading...