Page 78 • 700120S • ENTRON Controls, LLC.

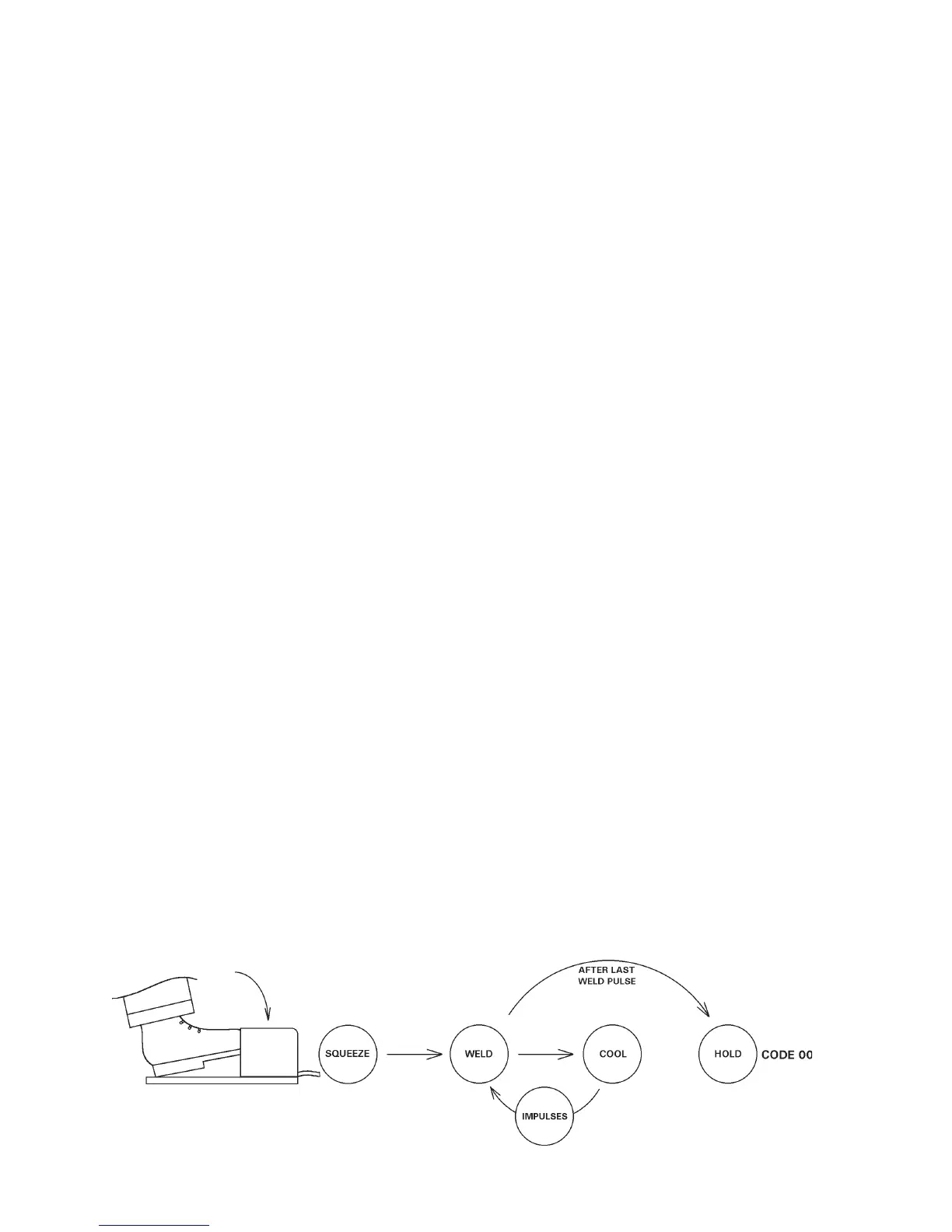

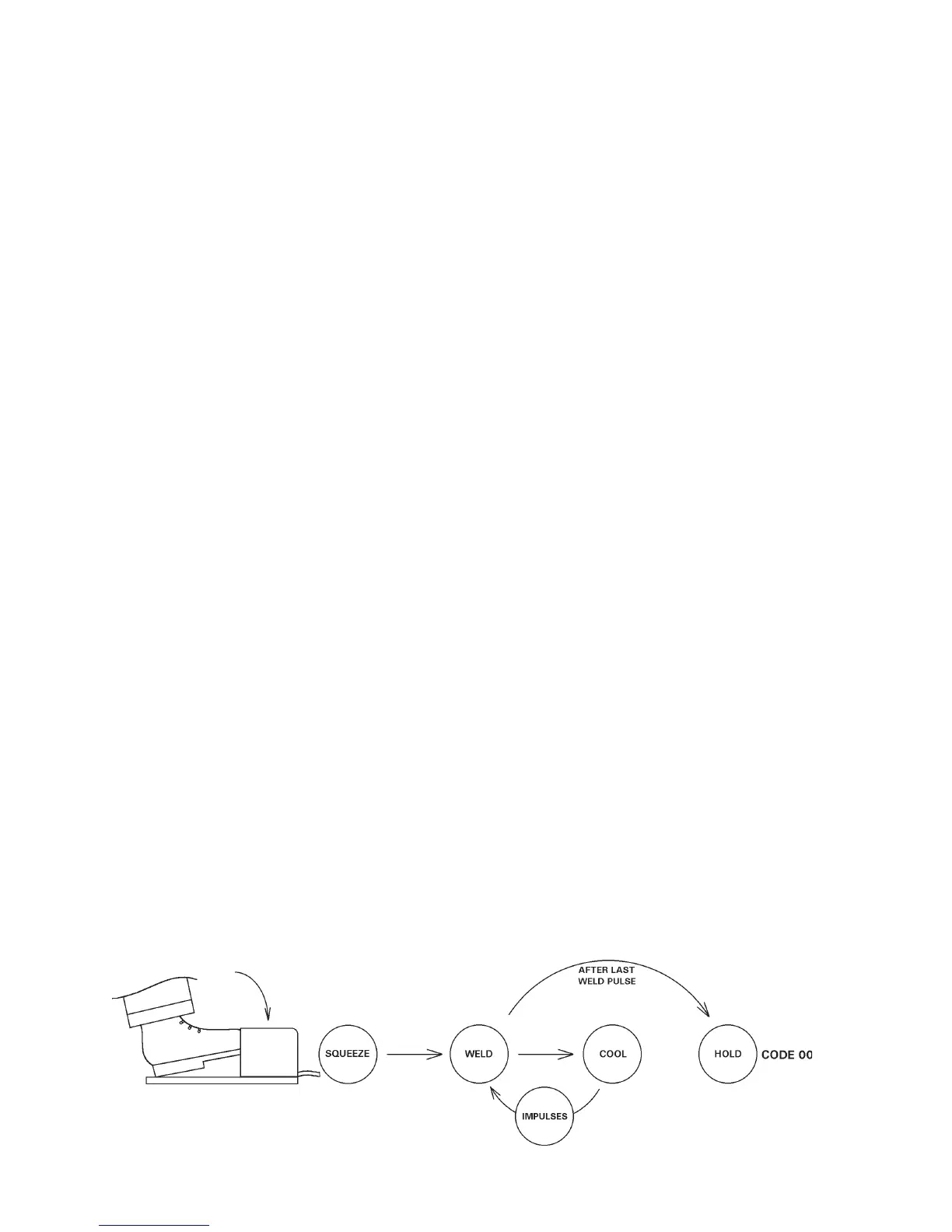

Figure 6-1. NON-REPEAT sequence

3. Program the schedule for the part to be welded. Place the work in the machine and set the

WELD/NO WELD switch (both on Control Panel and any External Weld/No Weld Switches)

to the WELD position. The machine is ready to weld.

4. If no standards have been set, it is recommended to use a short WELD count for initial setup

and welding. WELD count can be increased, the PERCENT CURRENT can be adjusted,

and welding transformer tap (if applicable) can be increased for the best weld. The most

efficient use of the control and welding machine will generally be made at the lowest welding

transformer tap, the highest PERCENT CURRENT setting, and the shortest WELD count.

5. For REPEAT operation, program CYCLE MODE to

0101

0101

01, and program OFF count to allow

sufficient time to reposition the part for subsequent welds.

6.2 CYCLE MODES

The EN1000/EN1001 can be programmed to operate in several CYCLE MODES. Each of the

50 possible schedules has a CYCLE MODE parameter that dictates the sequence of events that

will follow an initiation.

The CYCLE MODE are as follows:

0000

0000

00 = NON-REPEAT

0101

0101

01 = REPEAT

0202

0202

02 = CHAINED

0303

0303

03 = SUCCESSIVE

0404

0404

04 = CONDITIONAL SUCCESSIVE

0505

0505

05 = WAIT-HERE

The CYCLE MODE parameter is entered into a schedule when the control is in PROGRAM

mode with CYCLE MODE indicator LED illuminated.

6.2.1 NON-REPEAT – CYCLE MODE=

0000

0000

00

When any of the 50 possible schedules, having a CYCLE MODE setting of

0000

0000

00, is initiated by a

Pilot switch, the sequence executes as shown in Figure 6-1 (depending on the programmed

parameters).

Upon initiation, the programmed valve is energized at the beginning of SQUEEZE. If the Pressure

Switch is open, the control counts through the SQUEEZE time but does not begin counting

6.1 WELD SEQUENCE EXAMPLE (cont.)

Loading...

Loading...