Page 132 • 700120S • ENTRON Controls, LLC.

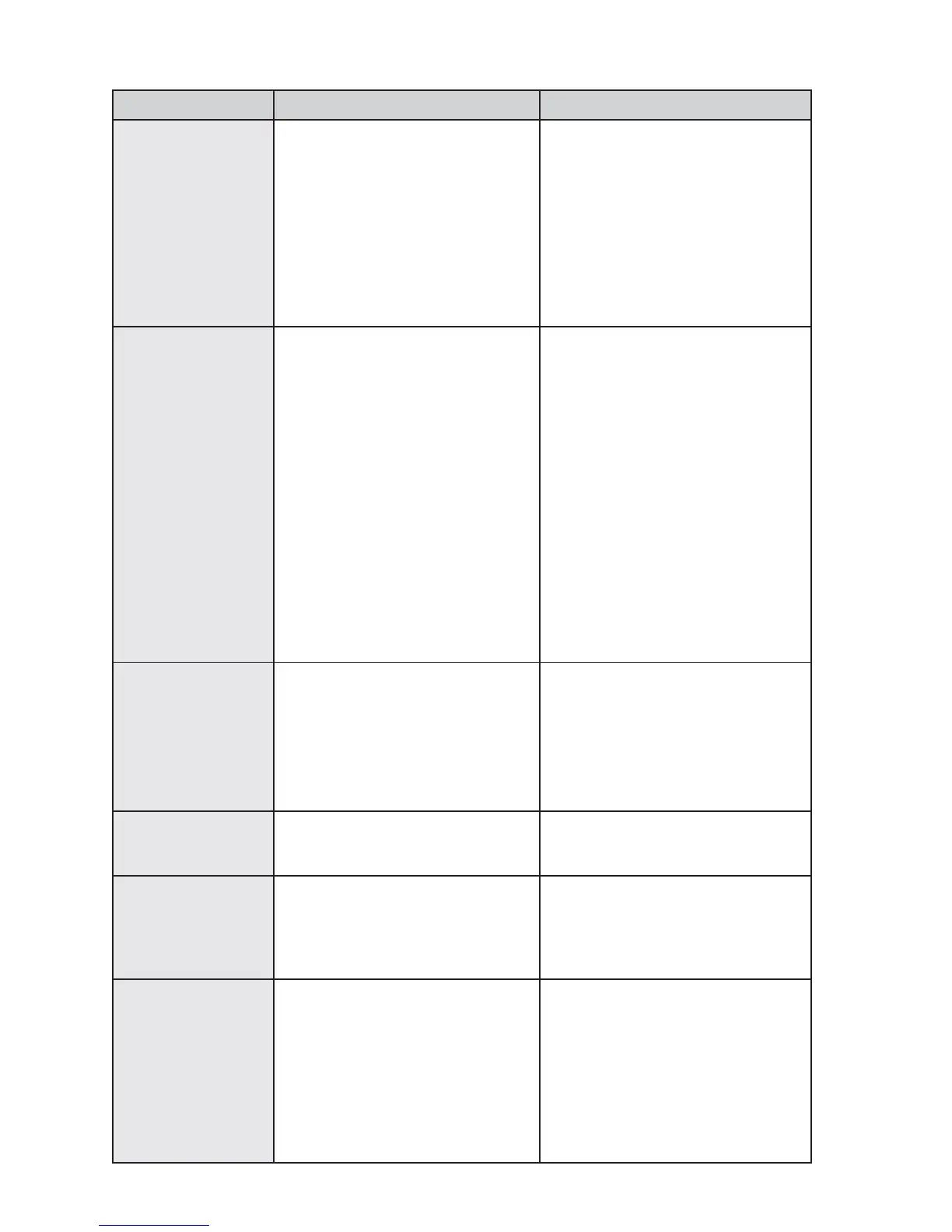

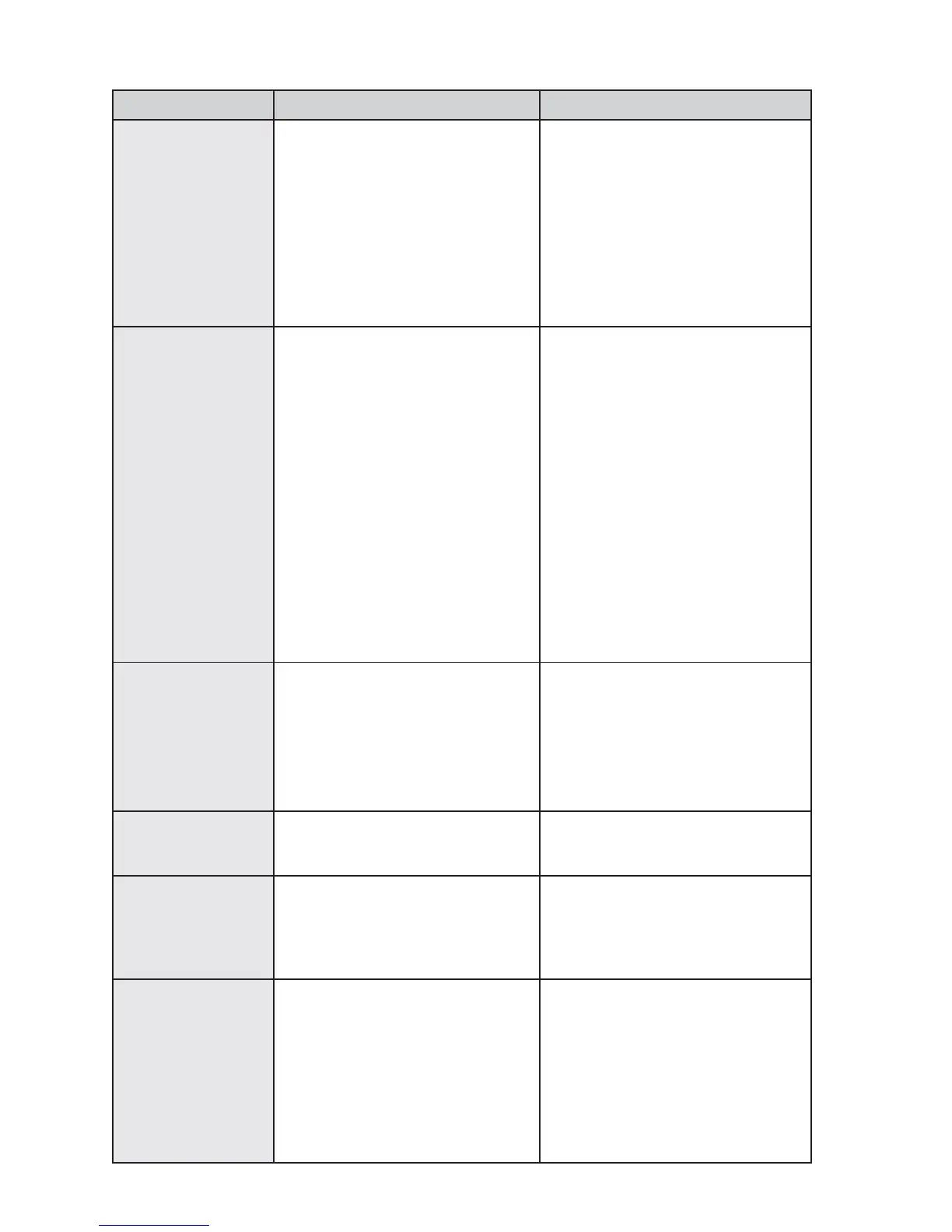

REMEDY

1a) Check that valve supply voltage is

not varying below tolerance, -15%.

1b) Check if valve coil is proper voltage.

1c) Insufficient air pressure.

1d) Loose connections in valve wiring.

2. Replace board with another

board stamped with same A/N.

3. Replace board. See Wiring

Diagram for correct A/N.

1a) Check both for proper operation

and/or loose wires on NW1 & GND.

1b) If no external Weld/No Weld

Switch is used, put jumper

across NW1 & GND.

2. Connect H1 and H2 to lugs in

the control.

3. Check corroded or open

connections. Be sure welding

electrodes close on work.

4. Replace board. See Wiring

Diagram for correct A/N.

5. Replace board with another

board stamped with same A/N.

6. Check for missing phase.

1. KVA demand for welding

transformer too high for input

power line. Check line voltage.

2. Check air system regulator.

3. Increase WELD count duration.

4. Properly dress tips.

1. Increase PERCENT CURRENT.

2.

Select correct electrode face diameter.

1. Check air supply and accessories.

2. Reduce WELD count duration.

3. Decrease PERCENT CURRENT.

4. Dress or replace tip with proper size.

1. Check air supply and accessories.

2. Check welding fixtures setup or

electrode alignment.

3. Check parts for proper fit-up.

4. Work should be free from

excessive dirt, paint and oxides.

5. Check all terminal and/or lug

connections inside the cabinet.

TROUBLE

Control initiates and

sequences properly,

but solenoid valve

chatters.

Control sequences

but will not weld.

Weld too cool.

Weld too small.

“HOT” Welds

Inconsistent Welds

POSSIBLE CAUSE

1. Solenoid valve coil.

2. Defective Control/Display PCB.

3. Defective Terminal Strip/Firing

Board.

1. External Weld/No Weld Switch

or WELD/NO WELD switch on

Front Panel of control.

2. Welding transformer not

connected.

3. Welding transformer secondary

open.

4. Defective Terminal Strip/Firing

PCB.

5. Defective Control/Display PCB.

6. Excessive ripple in secondary.

1. Line voltage drop.

2. Excessive pressure at electrodes.

3. WELD count too short.

4. Excessive tip “mushrooming”.

1. PERCENT CURRENT too low.

2. Electrode face too small.

1. Insufficient air pressure.

2. WELD count set too high.

3. PERCENT CURRENT set too high.

4. Electrode diameter too small.

1. Varying air pressure.

2. Work not square with electrodes.

3. Poor part fit-up.

4. Dirty material to be welded.

5. Loose connection.

11.2 TROUBLESHOOTING (cont.)

Loading...

Loading...