Brivo OEC 715/785/865 Mobile C-Arm X-Ray Product Service Manual

3-16

3.4.2. External Inspection

1. Cabling and Connector inspection

Check the interconnect cable for damage or other problems. Verify that connector on cable mates well

with the connector on C-Arm and that there are no bent or missing pins. Make sure the strain relief

attaches securely to both the interconnect cable and connector.

Anti-Static Drag Wires

Check the system’s antistatic drag wires. There is one suspended below the Workstation

and the other one underneath the C-Arm. Both wires must be securely attached to the

system and not be encumbered by debris.

Interconnect Cable and

Connector

Check Workstation’s Interconnect Cable for damage or other problems. Verify that Lemo

Connector on cable mates well with the connector on C-Arm, and that there are no bent

or missing pins.

Plug

Verify that the AC power cord and plug supplied with the system is the correct one for

customer facility.

2.

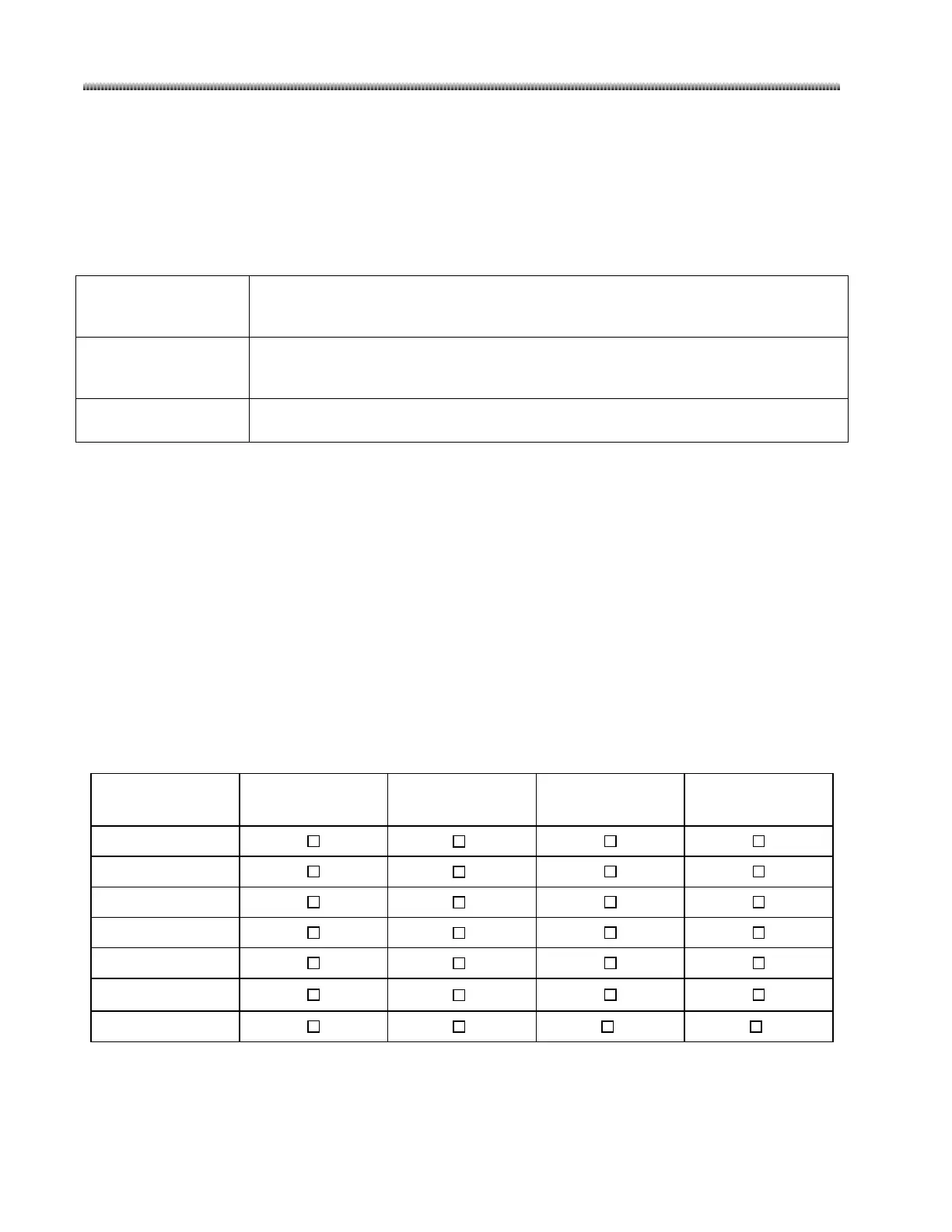

C-Arm Inspection

Inspect each C-Arm component listed under the heading C-Arm Inspection. Select one check box for

each item in the list. The choices are:

• No problem Found

• Loose or missing parts

• Broken or damaged parts

• Chipped or scratched paint

The items to inspect are grouped according to the larger visible, easily accessible assemblies and/or

modular parts of the system. Each inspection of an assembly item should include its visible component

parts and sub-assemblies.

C-Arm Inspection List:

Physical Location

found

parts

Damaged Parts

Scratched paint

Loading...

Loading...