Brivo OEC 715/785/865 Mobile C-Arm X-Ray Product Service Manual

7-66

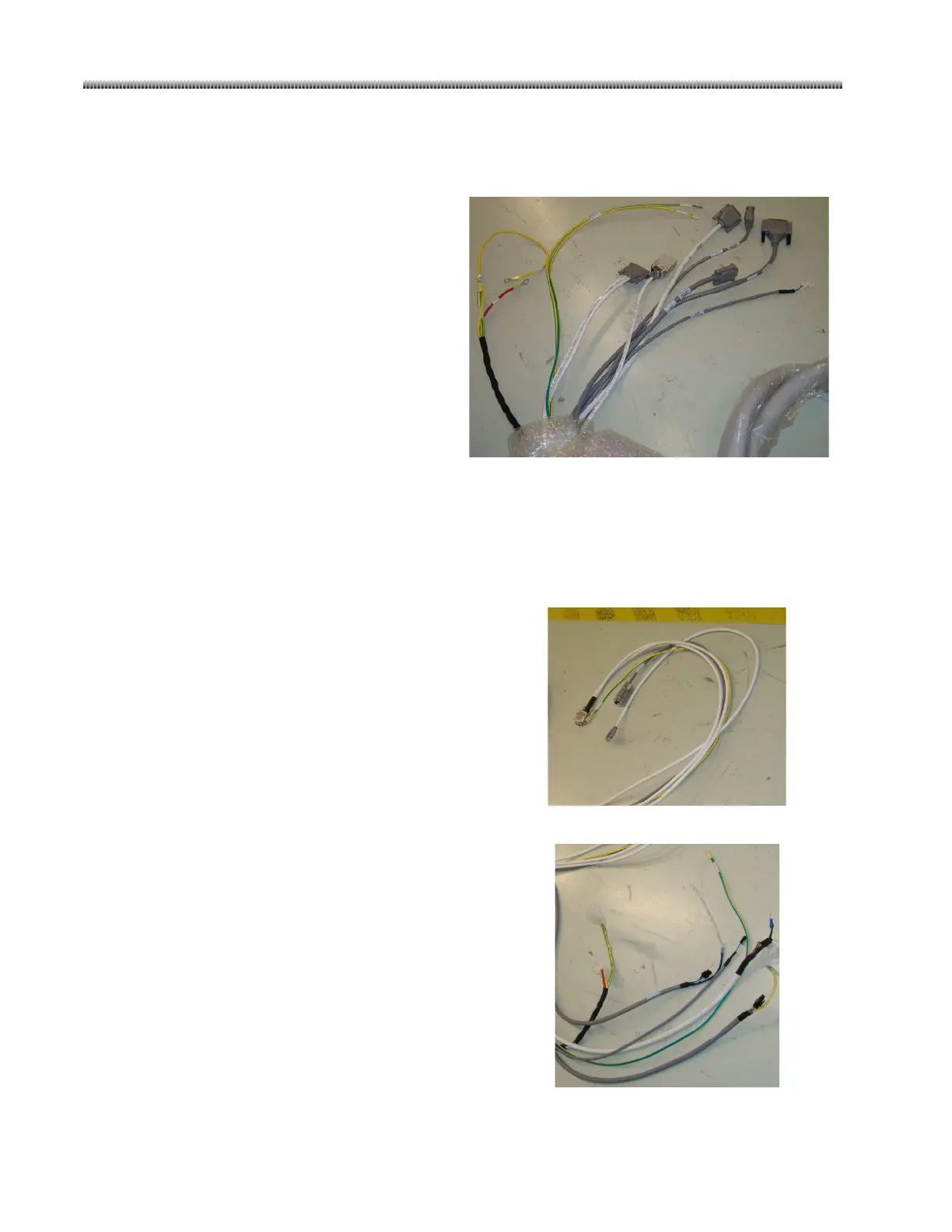

7.3.19. Bundle cable: (5075970)

Connector List (Mainframe Base Side):

Red

GND

Cap

GND

Connector List (C-arm_I.I. Side):

Connector List (C-arm_Monoblock Side):

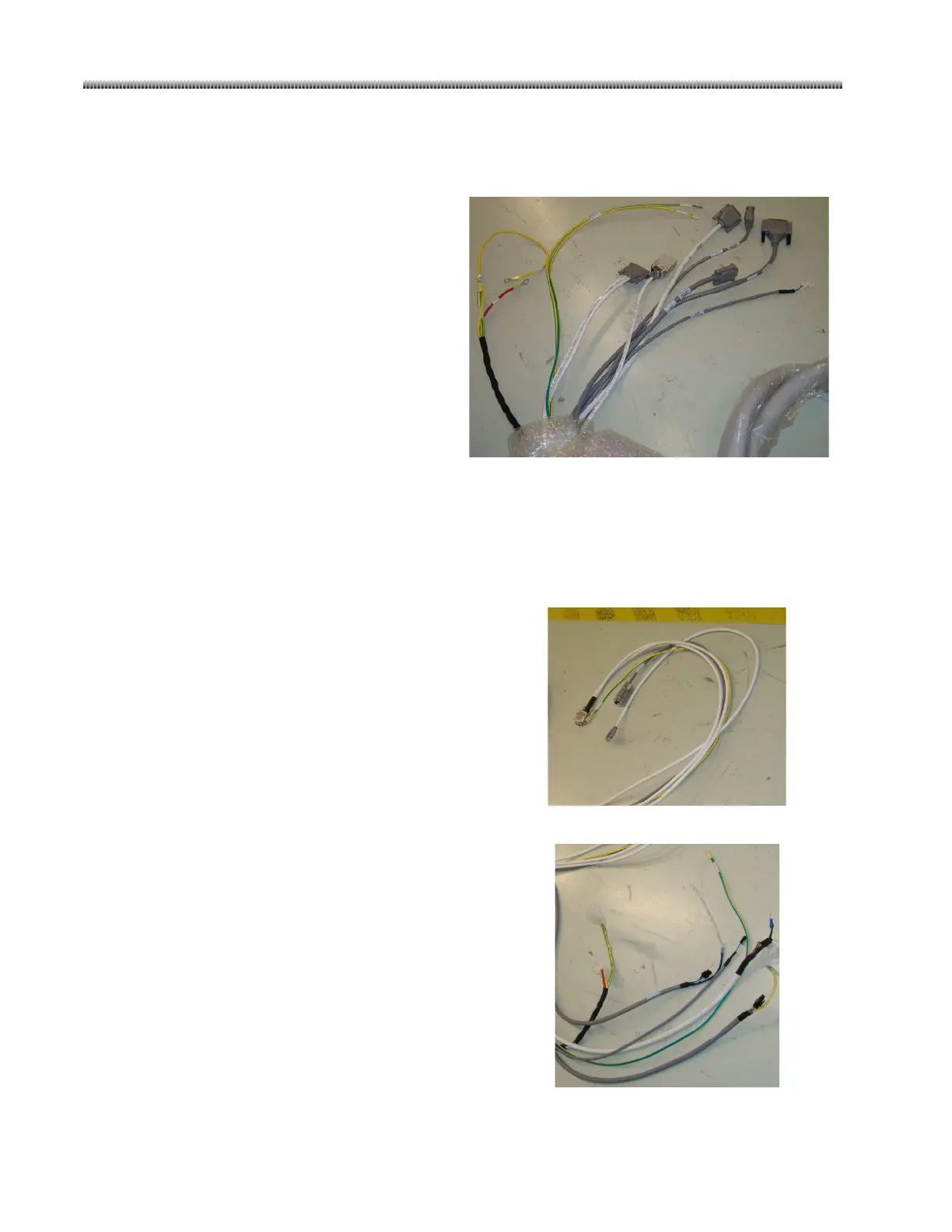

J10

J11

Removable Filter Proximity SW

Removable Filter Proximity SW

Loading...

Loading...