Section 4 - Alignment & Calibration

4-23

The program rotates the C-arm counter clockwise (i.e., the tank assembly moves away from

the front of the machine). When the C-arm hits the AP mechanical limit the first time,

7.

Press

<ESC>

.

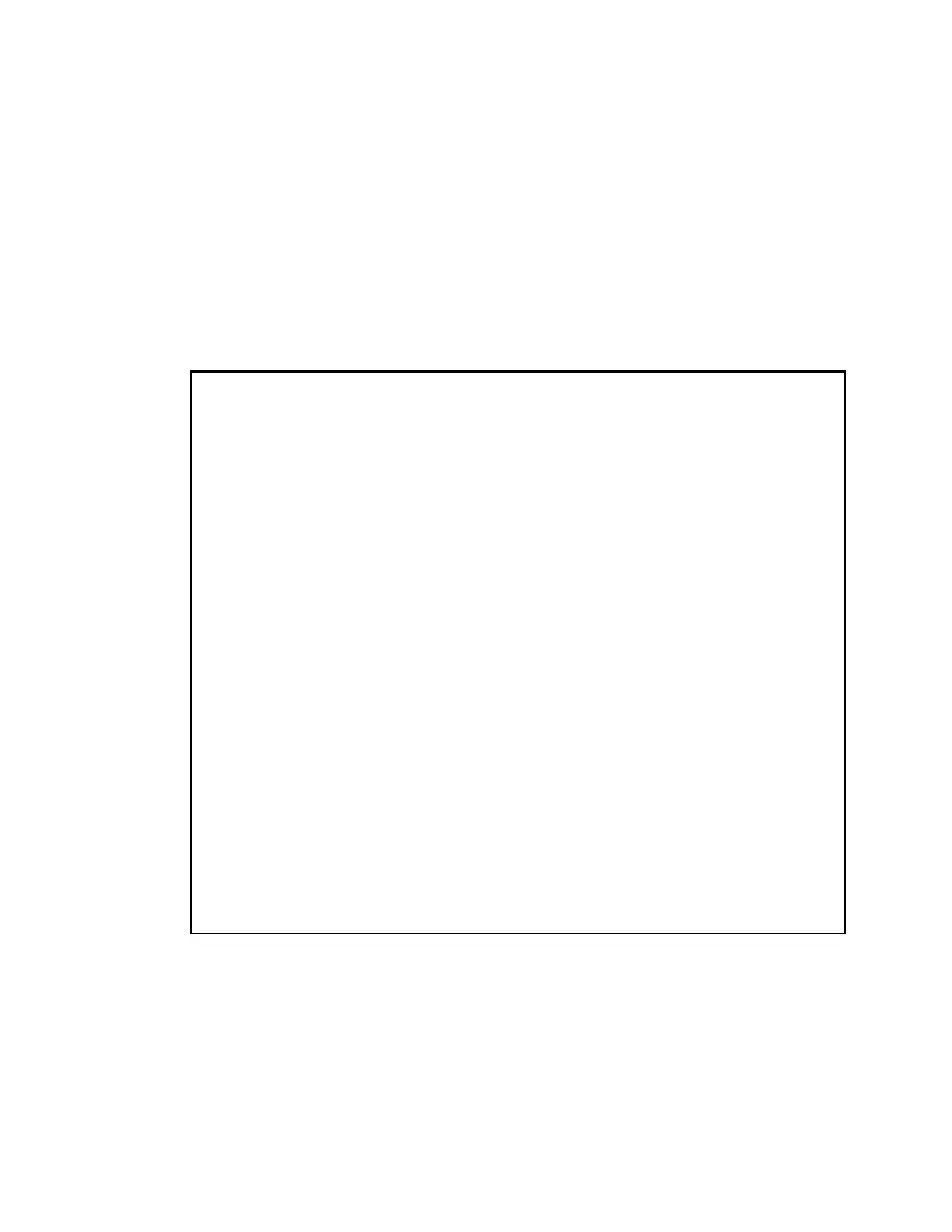

In the right hand column of the display, eight lines from the bottom (and highlighted in the

figure below), is the raw a/d readback of the motor encoder (in the example below, it is

2048). Manually rotate the encoder until the readback is 250±50 (i.e., in the range 200-300)

and then clamp the encoder to the drive shaft, making sure not to over stress the clamp.

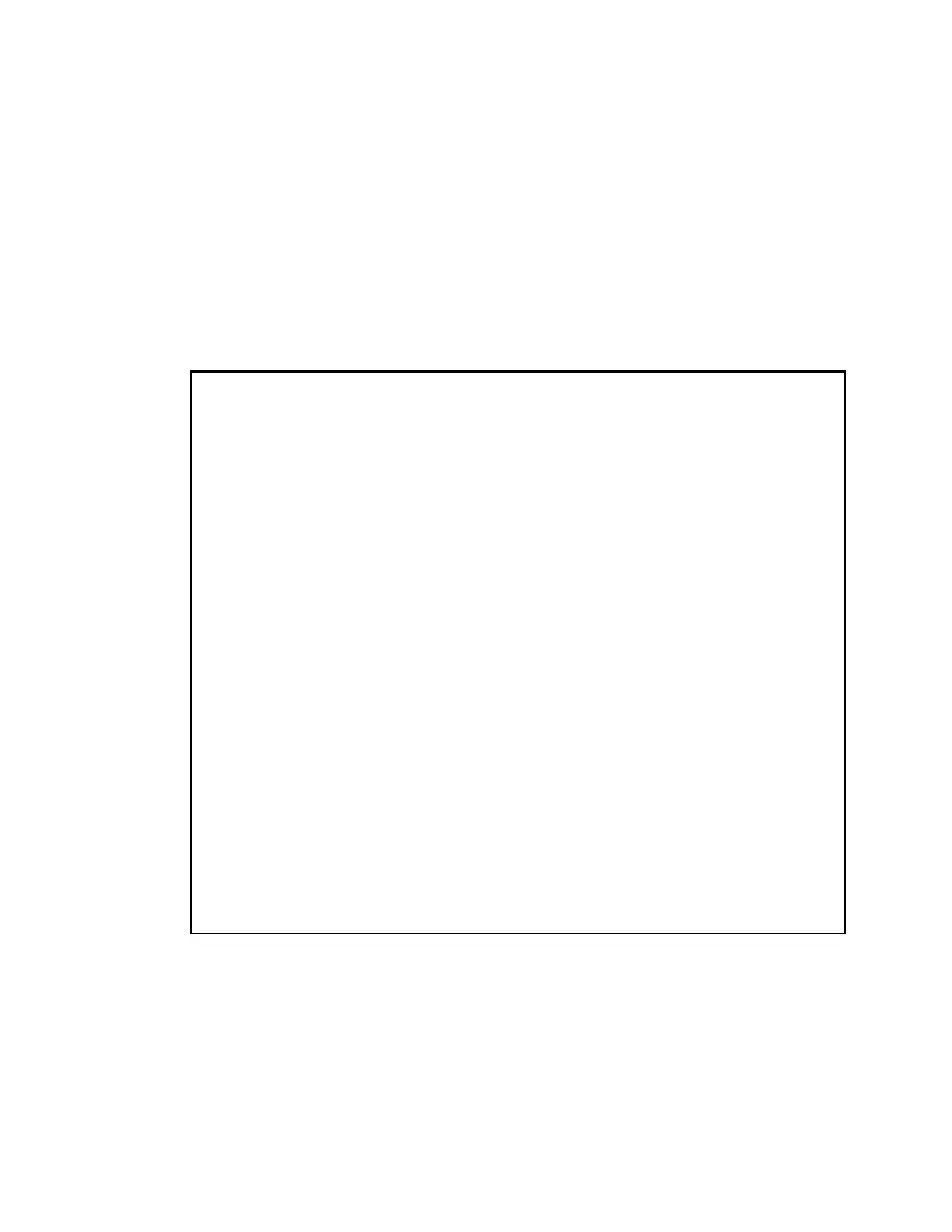

Before repeating the calibration procedure, rotate the C-arm back to approximately 0º by

8.

Typing the command MOVE_REL 1470

MotionState NONE OnLine 1

DeviceState E_OK EmergencyStop 0

MotionError E_OK InterlockInhibit 0

PosMotionSwitch 0 CollisionImminent 0

NegMotionSwitch 0 LocalMotionEnable 0

PosLimitSwitch NONE C/C Version 0.00

NegLimitSwitch NONE # C/C Interrupts 1619(0)

Position 1836 # DOS Interrupts 265

MoveState DONE StepStatus 0

FirstRate 33 AccelType 0

FinalRate 331 Direction 1

HoldPower OFF HoldPower 0

StepPower MEDIUM StepPower 2

AccelDistance 0 InputSwitches 3

AccelType 0

Position 2048

MinMotion 0 NegLimitPosition 250

MotionDetect 0 PosLimitPosition 3831

PosLimitPosition 5063 FirstRate 300

NegLimitPosition -1420 FinalRate 3000

PositionAverage 1 AccelSteps 0

DriverVersion 3.41 NumberOfSteps 50000

DeviceVersion 2.03 RateScaleFactor 1

MOTOR$AR> E_OK

Wait until the rotation completes and then repeat the calibration procedure above but now,

when the C-arm hits the AP mechanical stop,

9.

Press

<Enter>

.

The program prompts

Loading...

Loading...