Section 7 - Preventive Maintenance

7-3

1. Clean the AY and the TX guide rails using a dry, clean cloth.

Note:

DO NOT use a solvent such as alcohol or WD-40. If a solvent is needed to remove dirt

and/or gum buildup on the rail, be sure to thoroughly dry the rail before moving the

bearings. The solvent may harm the bearing grease.

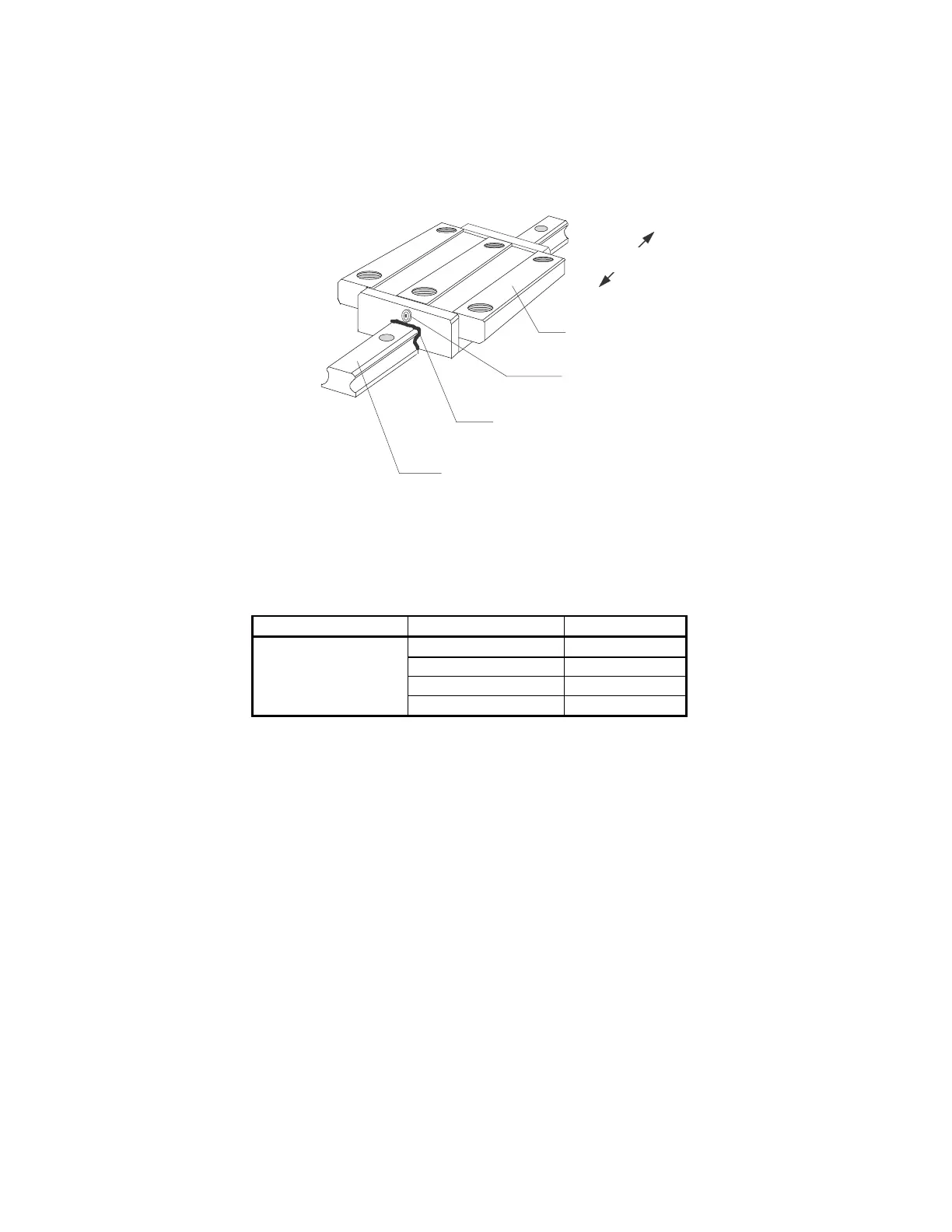

Seal

Guide Rail

Guide Bearing

Motion

Grease Fitting

Figure 7-1. Guide Bearing and Rail

2. Grease the guide bearings.

Note:

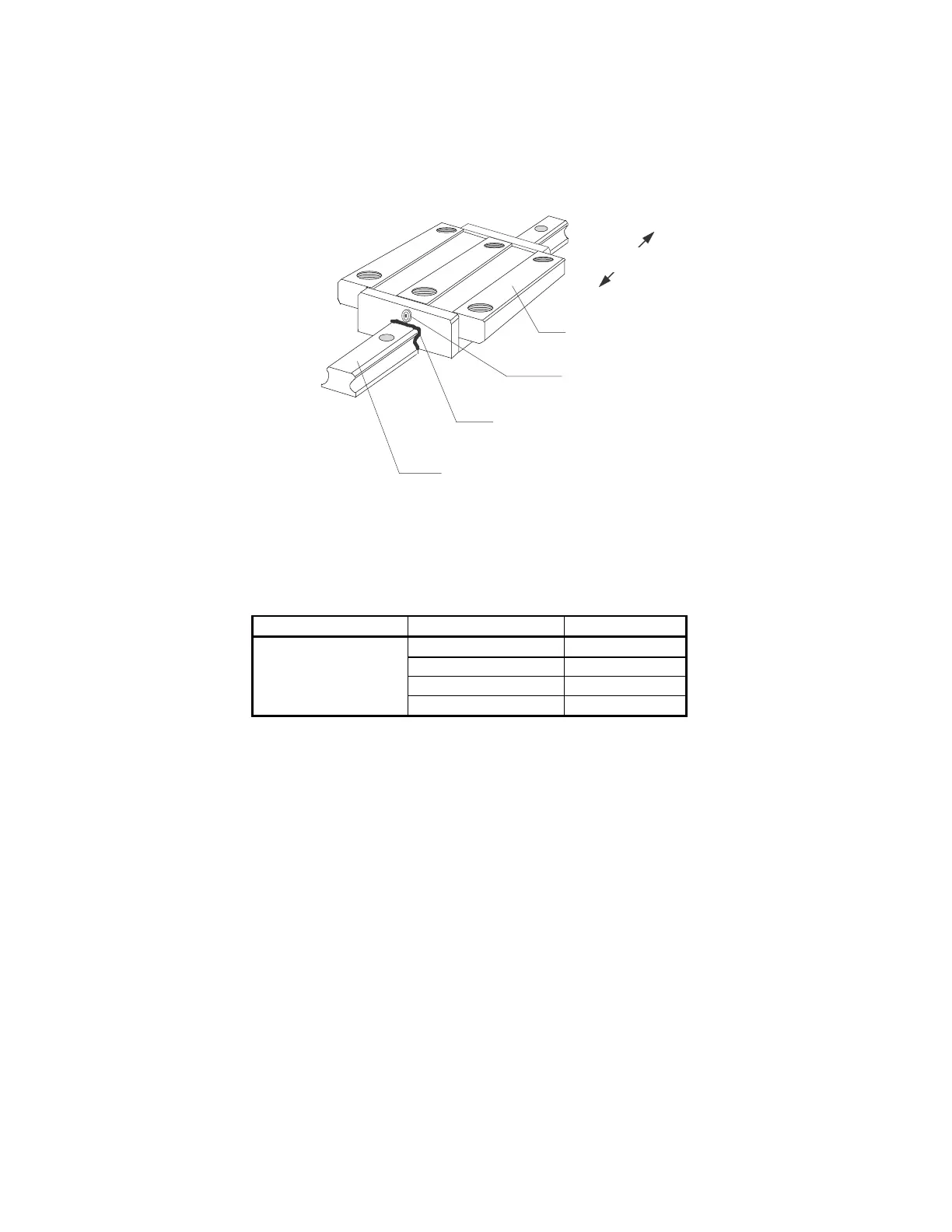

The bearings must be greased every 100km (62mi) of travel, depending on usage. This

may range between one and two years. The following table lists more information about

the grease to be used.

Generic Brand Names Manufacturer

EP-2 Lithium Beacon 325 ESSO

soap-based grease Alvania Grease RA Shell

Mobilux Grease No. 2 Mobil

Isoflex Super LDS 18 Kluber

Consult Field Service Headquarters for more information on obtaining the proper

tools, material, and procedure.

Loading...

Loading...