QDR

4500 Technical Manual

6-8

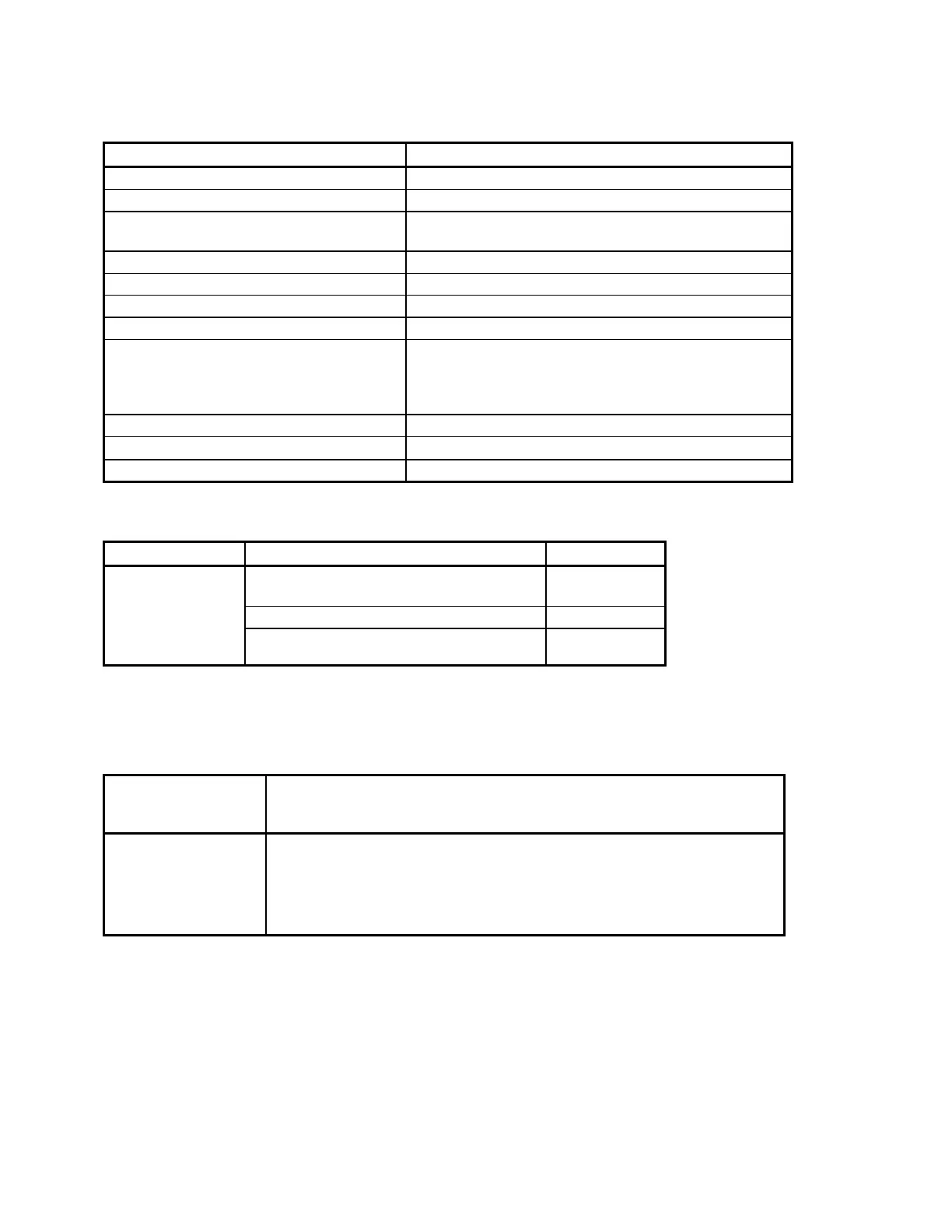

The following suggestions apply to a QDR 4500 system that exhibits no display:

Check... Refer to...

Tube kV peak potential Check Tube kV Peak Potential heading, Section 3

Tube current Check Tube Current heading, Section 3

X-ray production Field Service Preventive Maintenance heading,

Section 7

Signal strength and noise SUSQ in graphic mode,

Filter Drum is turning Figures 5-8, 5-18 through 5-23

Filter Drum belt Figures 5-18, 5-21

Green LEDs on C-Arm Interface board Figure 5-8, Section 8

No display may indicate a bad

Integrator/Multiplexor or Analog to Digital

Converter board

Refer to the Data Acquisition System heading, in

Section 2 of this manual, for block diagrams and

interconnection charts for the Integrator/Multiplexor

and Analog/Digital Converter boards

Check aperture position and aperture belt

Aperture Calibration

heading, Section 4

Also...

Run the hardware checker SQCHECK, 080-0476, F/S Tools disk

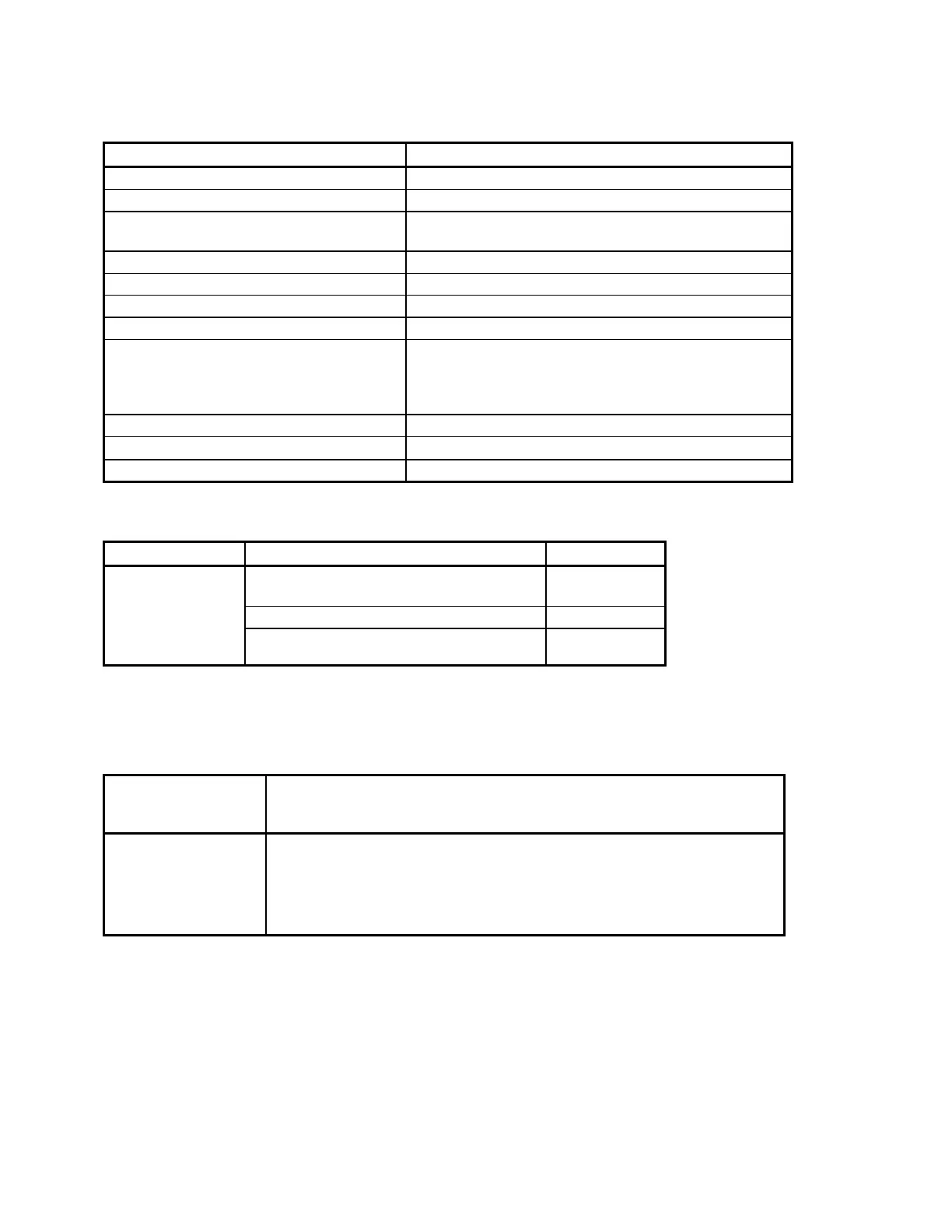

TARGETING/LASER PROBLEMS

If... Check... Refer to...

Object being

scanned appears

Detector array. It may be too far forward

or back inside the upper arm assembly.

Figure 5-10

to the left or right

Laser alignment Page 4-22

of the scan

window

Run...

BIGFLAT

DATA COMMUNICATIONS PROBLEMS

Data communications problems occur between the computer and the scanner. Refer to the

following table:

Error messages

usually include the

keywords:

Check the:

Message

Packet

Sent

•

Received

Digital Signal Processor PCB. If IC is not seated properly, replace the

board.

Data, power, and ribbon cables for proper seating.

•

Device states in the SQDRIVER for errors. If a device is stated as

“E_TIMEOUT”, it is suspect.

Loading...

Loading...