(E) 12-1

LH71A / LH72

12. Specifications

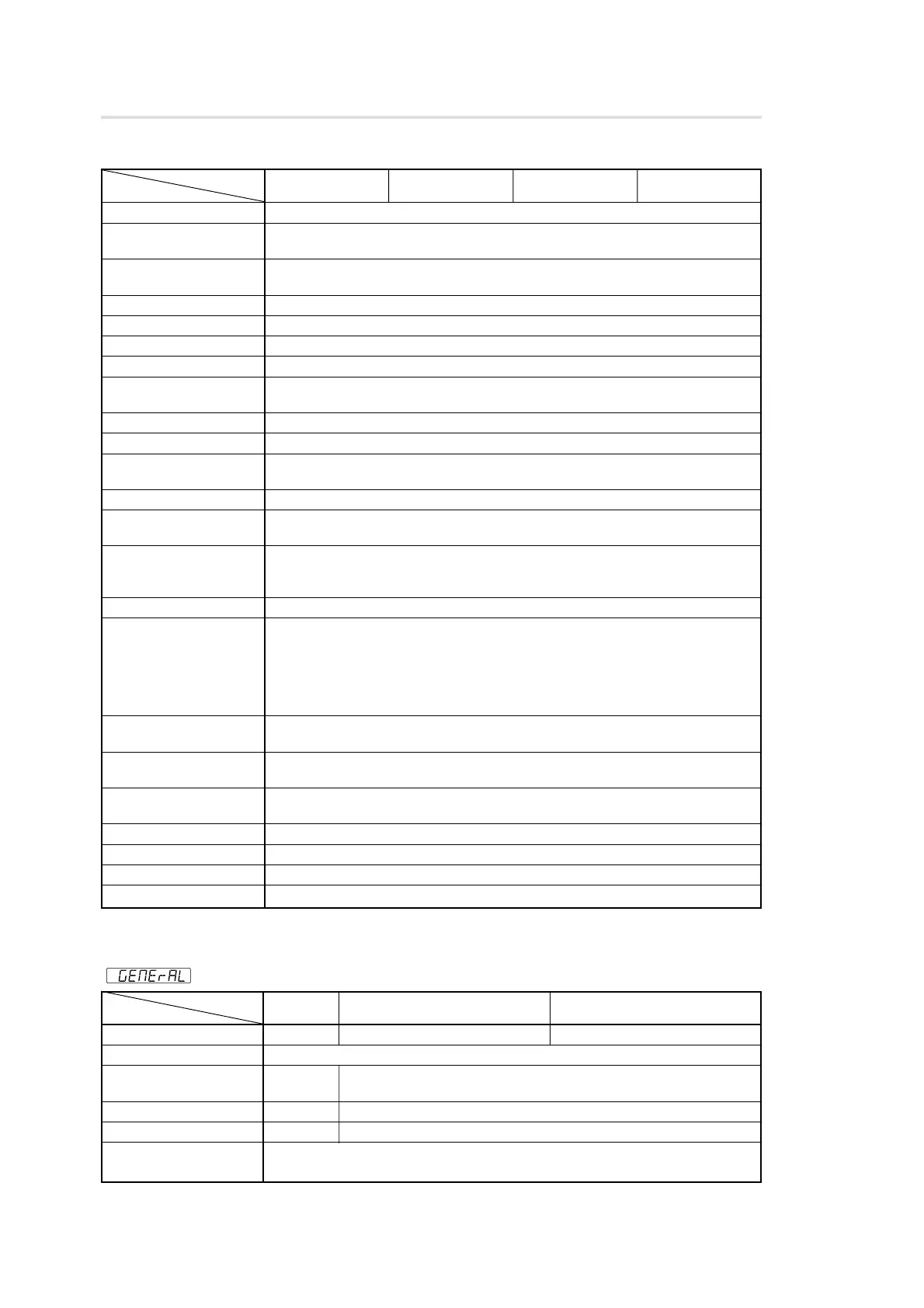

Common Specifications

Function

Model name

LH71A-1 LH71A-2 LH71A-3 LH72-3

Display 7 digits and minus display, Color amber

Connectable measuring unit

GB-ER, SJ300 series, SJ700A, PL20C series (Direct)

DG-B (Necessary to use the conversion adaptor which is sold separately.)

Measuring unit input Standard: 0.1 µm, 0.5 µm, 1 µm, 5 µm, 10 µm, 1 s, 10 s, 1 min, 10 min

resolution Expanded: 100 µm, 50 µm, 25 µm, 20 µm, 2 µm, 0.05 µm and 1 degree can be added.

Display resolution

Measuring unit input resolution or higher and diameter display (except for angle display)

Input signal A/B quadrature signal, Z signal (Conforms to EIA-422.)

Minimum input phase difference

100 ns

Quantization error ±1 count

Alarm display

Measuring unit disconnected, Excess speed, Maximum display amount exceeded,

Power failure, Error in stored data

Reset Resettable by key switch or remote reset.

Preset It is possible to store/call 3 kinds of numbers.

Reference point detection

The reference point of the measuring unit can be detected, and the datum point

can be relocated (during connection of measuring unit with a reference point)

Data storage The value displayed before the power was turned off and setting values are stored

Linear error compensation

A fixed compensation is applied to the measuring unit’s count value.

Compensation amount Standard: ±600 µm/m (Expanded: ±1000 µm/m)

Segmented error

The movement range of the measuring unit with a reference point can be divided into a

compensation

maximum of 32 sections, and error compensation is performed for each of these sections.

Compensation amount: ±600 µm (at each section)

Scaling Scaling factor: 0.100000 to 9.999999

Machining coordinates can be programmed (number of program steps: 850 max.)

1. Manual programming by key switch

Program

2. Automatic programming by playback

3. Mirror image during program execution

4. A canned cycle (bolt hole, line hole, simple R cutting) can be inserted in the program.

(LH71A only)

Angle display

Can be displayed as an angle value when the Digiruler is pasted to the arc surface,

and the diameter and Digiruler resolution are entered

Sleep

The display is turned off when no operations are made for a preset time.

(The time can be set.)

Power supply DC 12 V Rating 0.75 A Max. 1 A

AC 100 to 240 V ±10% (When using AC adaptor which is sold separately.)

Power consumption Max. 32 VA (connected at AC power supply)

Operating temperature range

0 to 40°C (no condensation)

Storage temperature range –20 to 60°C (no condensation)

Mass Approx. 1.5 kg

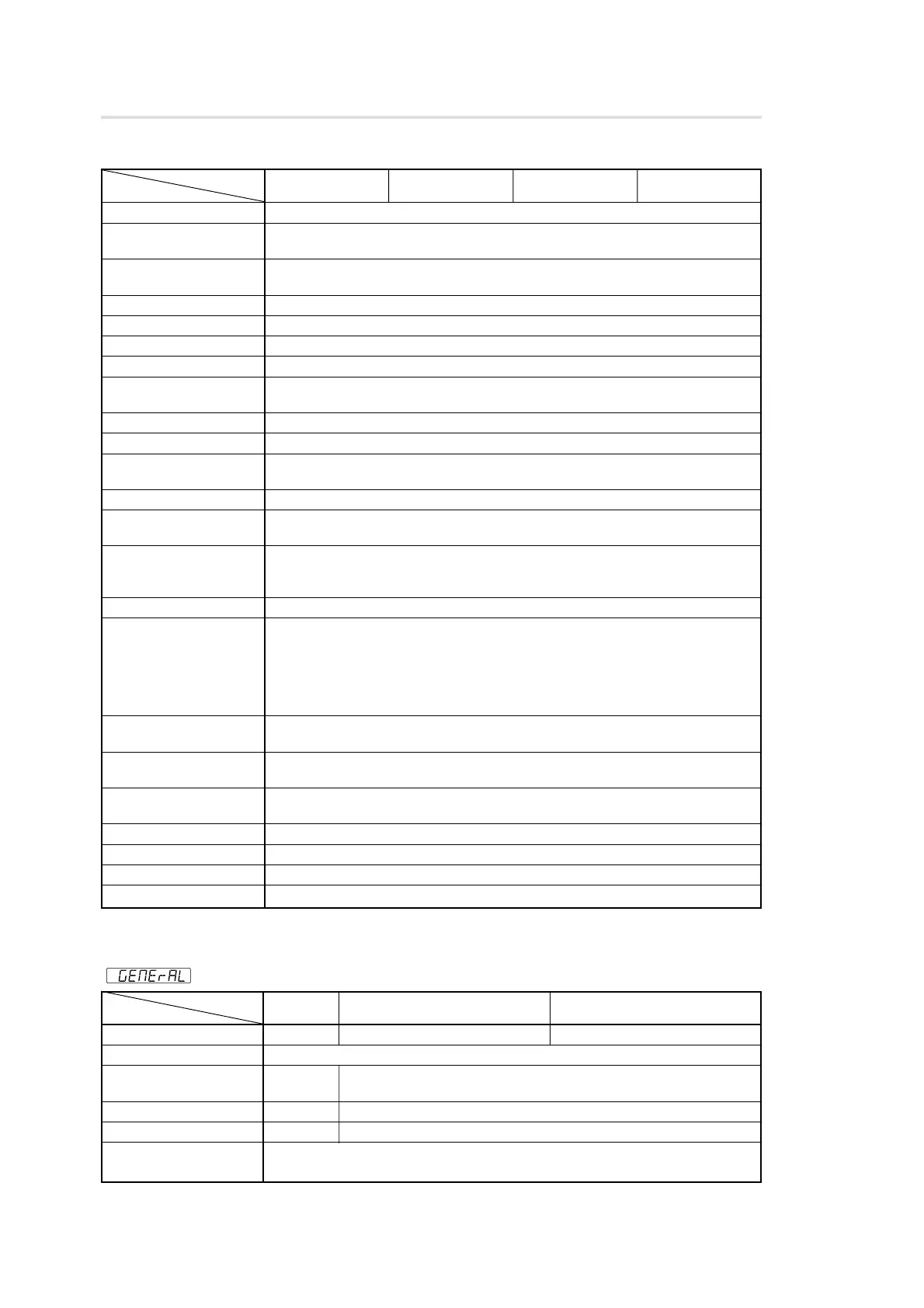

When the LH71A general-purpose applications or milling machine function are selected

( setting in the model type selection mode of the basic settings)

Function

Model name

LH71A-1 LH71A-2 LH71A-3

Display axes 1-axis 2-axis 3-axis

Multi datum point 150

Bolt hole circle –

Displays coordinates for opening equidistant holes along the

perimeter of a designated diameter

Simple R cutting – Display coordinates for simple R cutting

Line hole –

Displays coordinates for opening equidistant holes along a designated straight line

Touch sensor Combined with the touch sensor (sold separately), the datum plane can be detected, etc.

1. Hold function 2. Load function 3. Centering function

Loading...

Loading...