7-10 (E)

7. Operation Method

LH71A / LH72

7-2-8. “Tool Master (Tool No. 1)” and “Tool Offset (Tool No. 2 ~)”

(for LH71A lathe applications and LH72)

Tool master (tool No. 1)

A tool master is a datum point used when setting the tool offset.

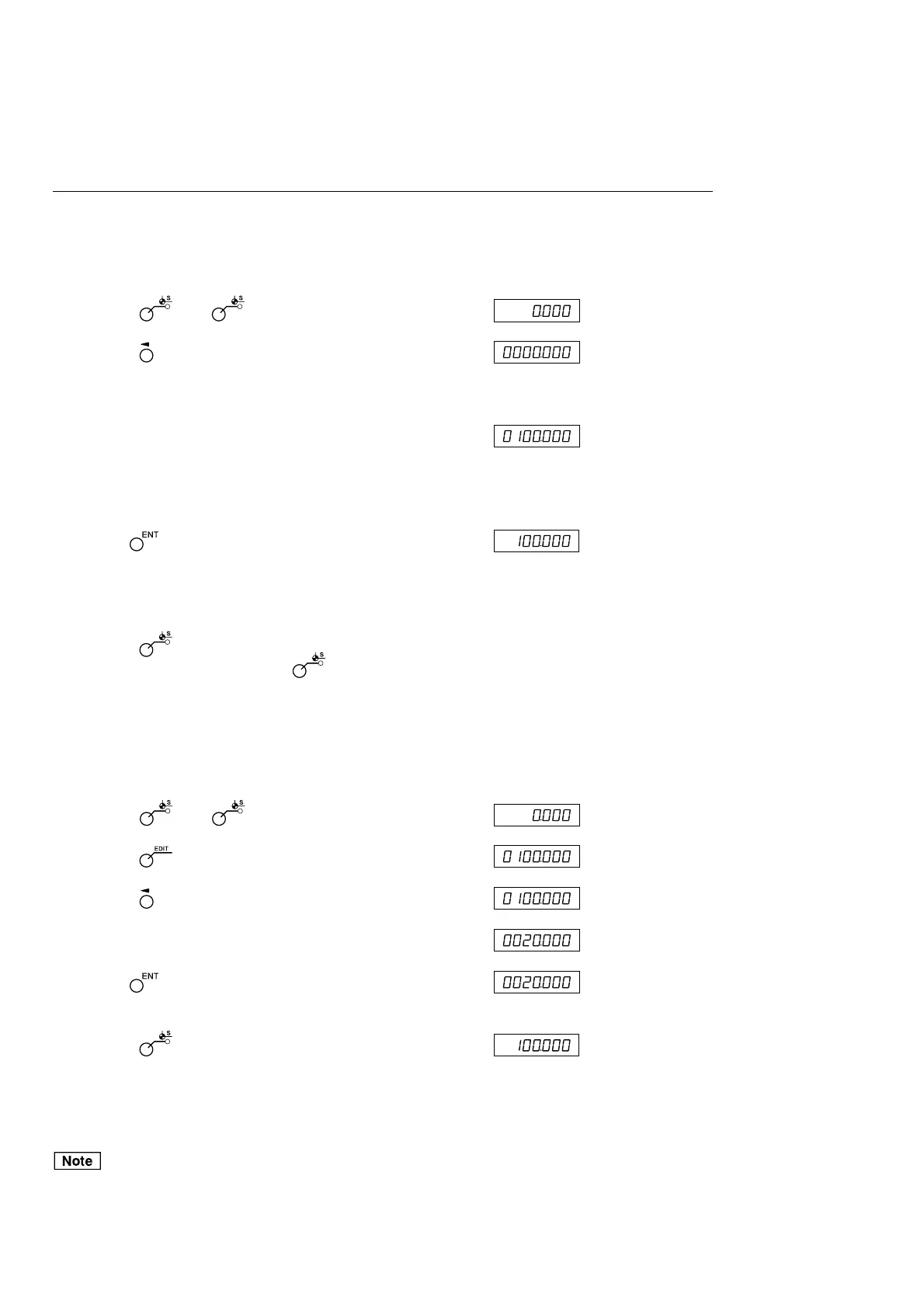

<Setting and calling a tool master> Display

1 Press the key. ( lamp lights up)

2 Press the key corresponding to the axis to be set.

If a tool master is already set, the numerical value of the

previously set tool master is displayed.

3 Use the numeric key to enter the value.

∗ When you want to use a value that was set previously, there

is no need to enter the value using the numeric key. Proceed

to step 4.

4 Use the key to finalize the setting.

The current value becomes the value of the tool master.

When the tool master is set, the set value is stored in the

memory.

5 Press the key.

The system exits the tool master. ( lamp goes out)

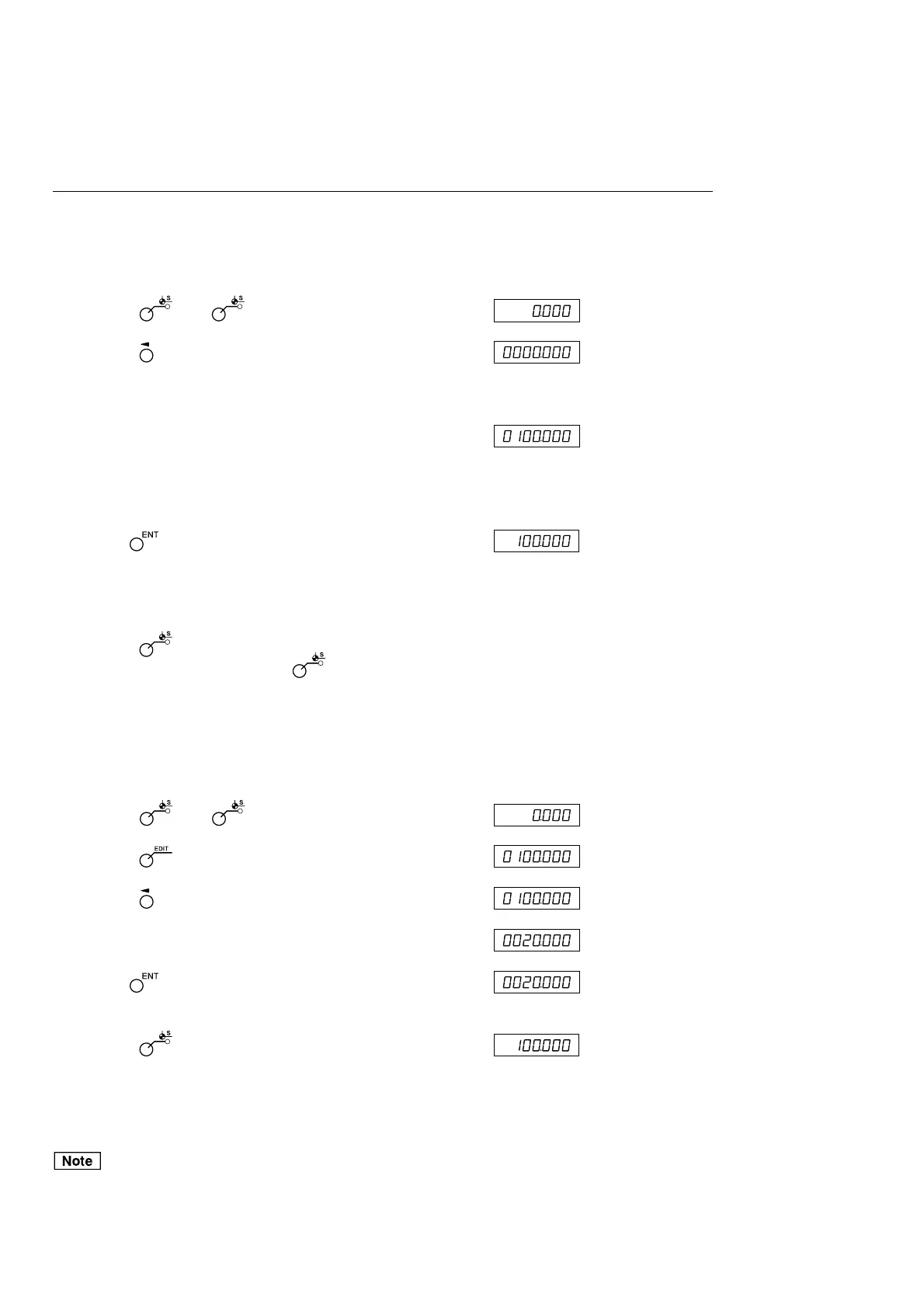

<Editing a tool master>

You can edit a stored tool master.

Display

1 Press the key. ( lamp lights up)

2 Press the key.

3 Press the key corresponding to the axis to be edited.

4 Use the numeric key to enter the value.

5 Use the key to finalize the setting.

(Tool master value 20 is stored in No. 1.)

6 Press the key.

Tool master editing is completed.

∗ When using an edited tool master, carry out <Setting and

calling a tool master>.

ABS indicator remains on during datum point mode.

The tool master (No. 1) is used as the basis of linear compensation.

(Position of tool master value 0 = Compensation amount 0)

(The tool master

value for each axis

is displayed.)

(Example: 100.000)

(Example: 20.000)

(Current value

display)

(Current value

display)

Loading...

Loading...