Circuit

Breaker

Amps Wire No. Description of Items Protected

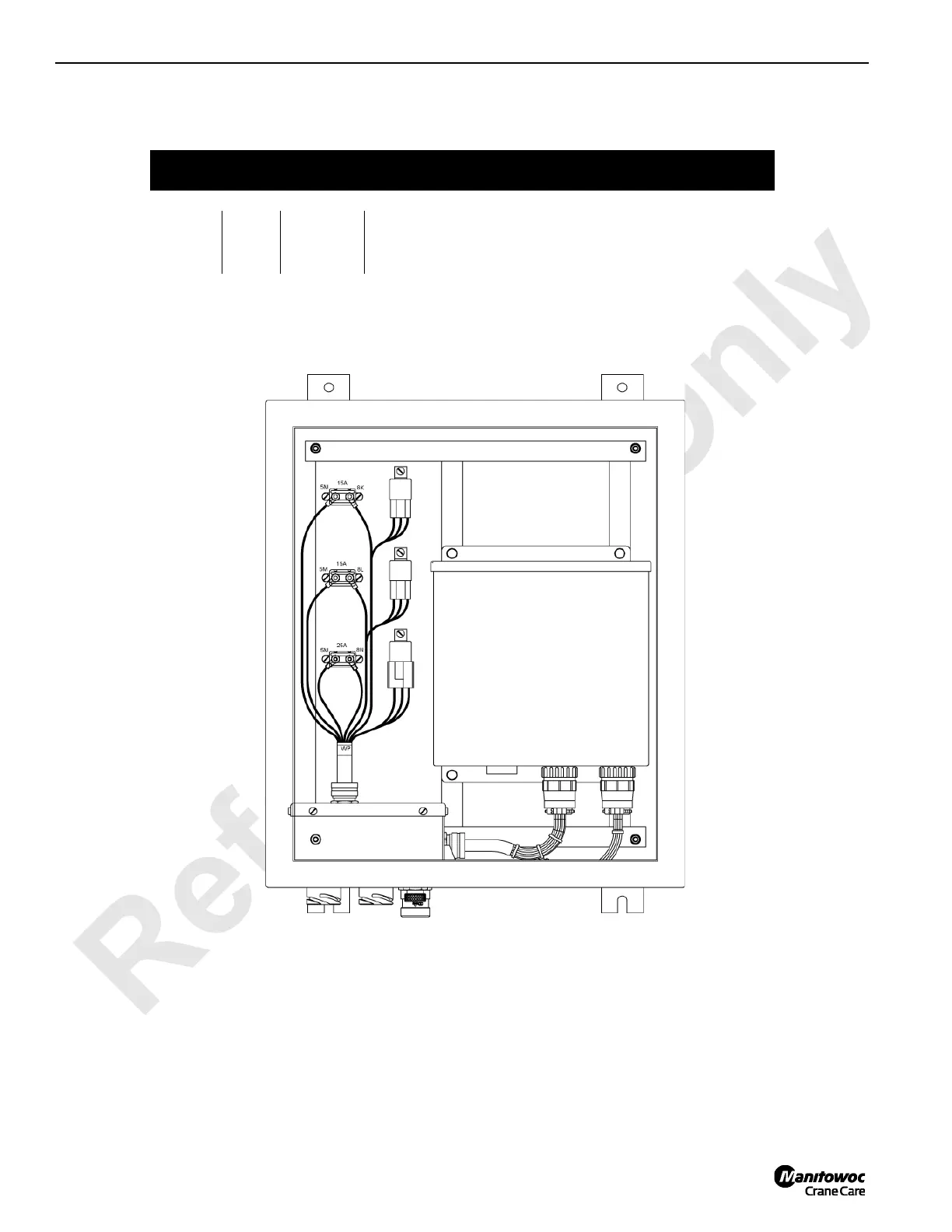

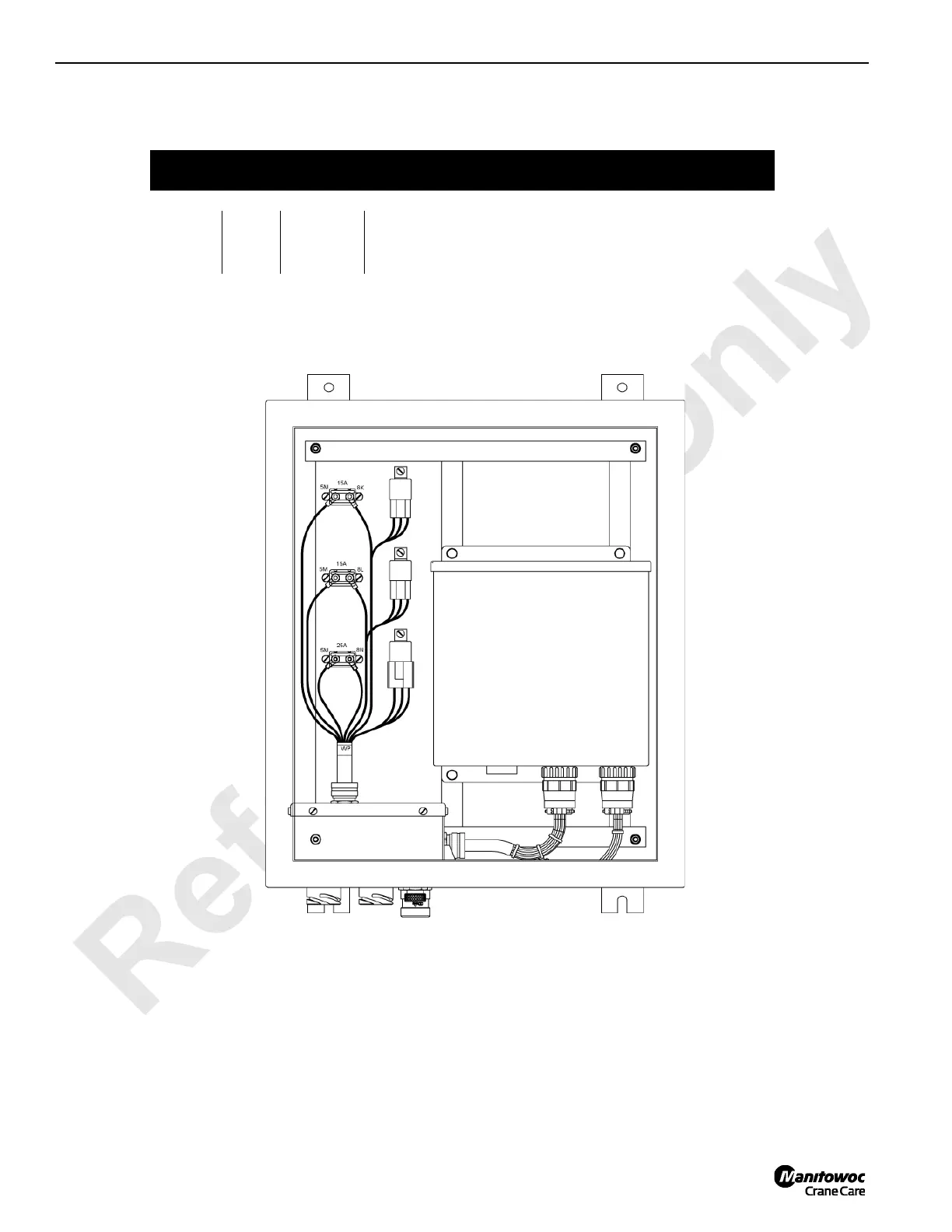

MAX-ER 2000 Enclosure Junction Box

1 15 8K Main Junction Box

2 15 8L Drum 9 Pawl Relays

3 25 8N MAX-ER Programmable Controller

A

1

9

1

0

3

FIGURE 3-7

MAX-ER 2000 Junction Box Enclosure

1

2

3

Main Junction Box

MAX-ER

Programmable Controller

Loading...

Loading...