POWER TRAIN 2250 SERVICE/MAINTENANCE MANUAL

7-20

Published 11-06-15, Control # 040-13

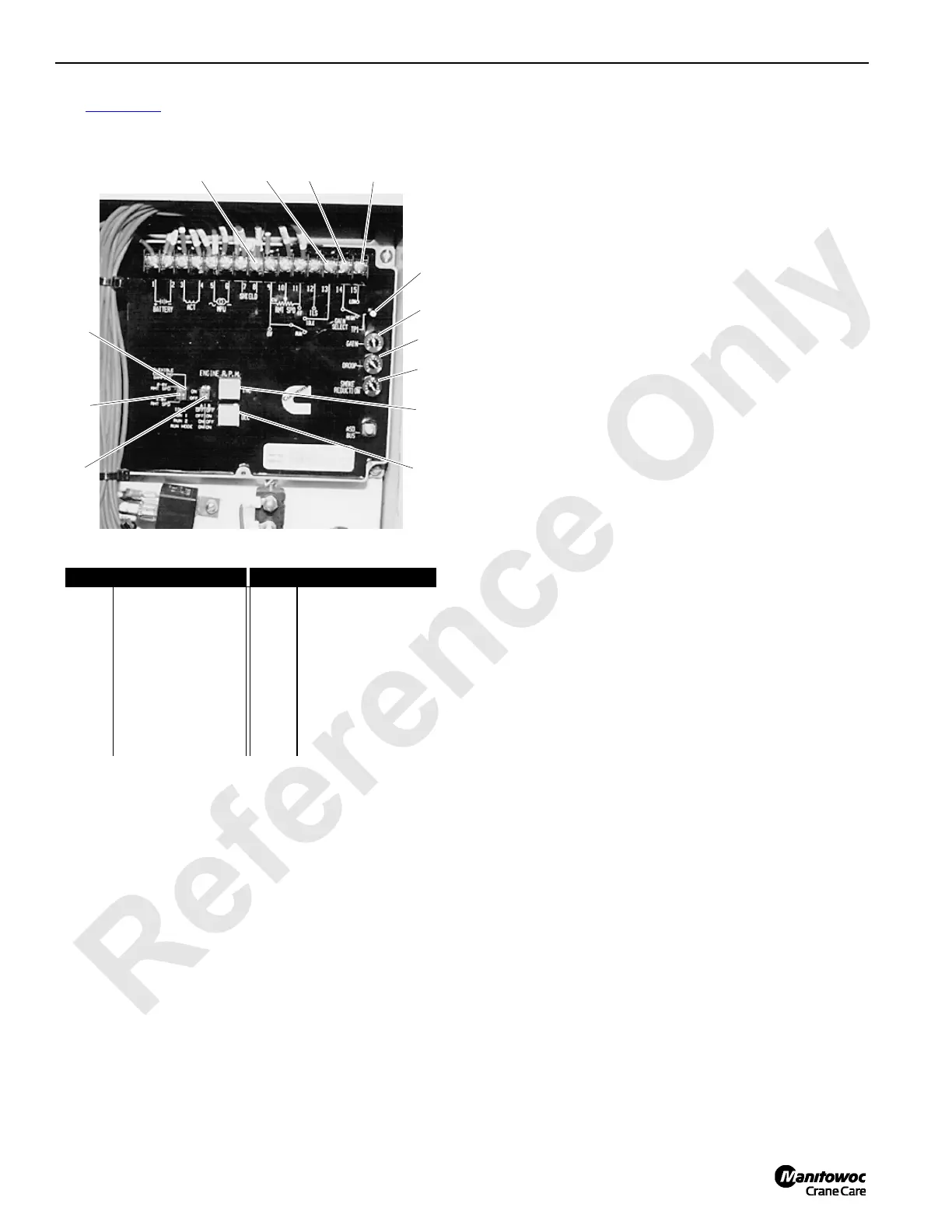

See Figure 7-25 while performing the fuel control adjustment

steps.

The engine clutch must be engaged for all steps. It is

normal for the idle speed to be as high as 1,500 rpm when

engine clutch is disengaged.

If the specified engine speeds cannot be obtained during the

adjustment steps, the engine speed sensor (on engine

flywheel housing) may not be adjusted. To adjust engine

speed sensor:

• Turn sensor out several turns.

• Turn sensor in until it lightly bottoms out against a

flywheel gear tooth.

• Turn sensor out 1/2 turn.

• Securely tighten jam nut to lock sensor adjustment.

1. In cab, move hand and foot throttles to low idle.

2. Stop engine.

3. Open cover on junction box.

4. Remove jumper wire between terminals #14 and #15, if

there is one.

5. Set potentiometers to following positions:

a. Gain potentiometer to mid-position (50). This setting

should prevent the engine from surging.

b. Droop potentiometer fully counterclockwise (0).

c. Smoke potentiometer fully counterclockwise (0).

6. Set Flexible Coupling Damping switch to on position.

7. Set RMT SPD switch to 4-8V position.

8. Set A/B switches to RUN 1 position — A switch off and

B switch on. This is the controlled low idle setting.

9. Start engine (hand throttle fully forward and foot throttle

fully raised to low idle).

10. Scroll to engine speed on digital display screen. See

digital display to monitor engine speed during remaining

adjustment steps.

11. Using ENGINE RPM buttons in junction box, press INC

(increase) or DEC (decrease) button to set engine

speed as close to 1,000 rpm without going over.

12. Stop engine.

13. Set A/B switches to RUN 2 position — A switch on and B

switch off.

14. Start engine and run it at full throttle (hand throttle fully

back or foot pedal fully down).

15. Press INC or DEC button to set engine speed as close to

2,100 rpm without going under.

16. Stop engine.

17. Set A/B switches to RUN MODE position — A switch on

and B switch on.

18. Test hand and foot throttles for proper full throttle

operation, as follows:

a. With

hand throttle pulled back fully (foot throttle up

fully), engine speed must be as close to 2,100 rpm

without going under.

b. With foot throttle pressed down fully (hand throttle

forward fully), engine speed must be as close to

2,100 rpm without going under.

c. Repeat steps 13 – 18b until speed in RUN 2 position

matches speed in RUN MODE as closely to 2,100

rpm without going under.

d. If proper speed cannot be obtained, check foot

throttle linkage adjustment.

FIGURE 7-25

Junction Box on Front of Engine

P131

Item Description Item Description

1 Terminal 9 8 Smoke Reduction

Potentiometer

2 Terminal 13 9 INC Button

3 Terminal 14 10 DEC Button

4 Terminal 15 11 A/B Switches

5 Terminal TP-1 12 RMT SPD Switch

6 Gain Potentiometer 13 Flexible Coupling

Damping Switch

7 Droop Potentiometer

1

2

3

4

5

6

7

8

9

10

11

12

13

Loading...

Loading...