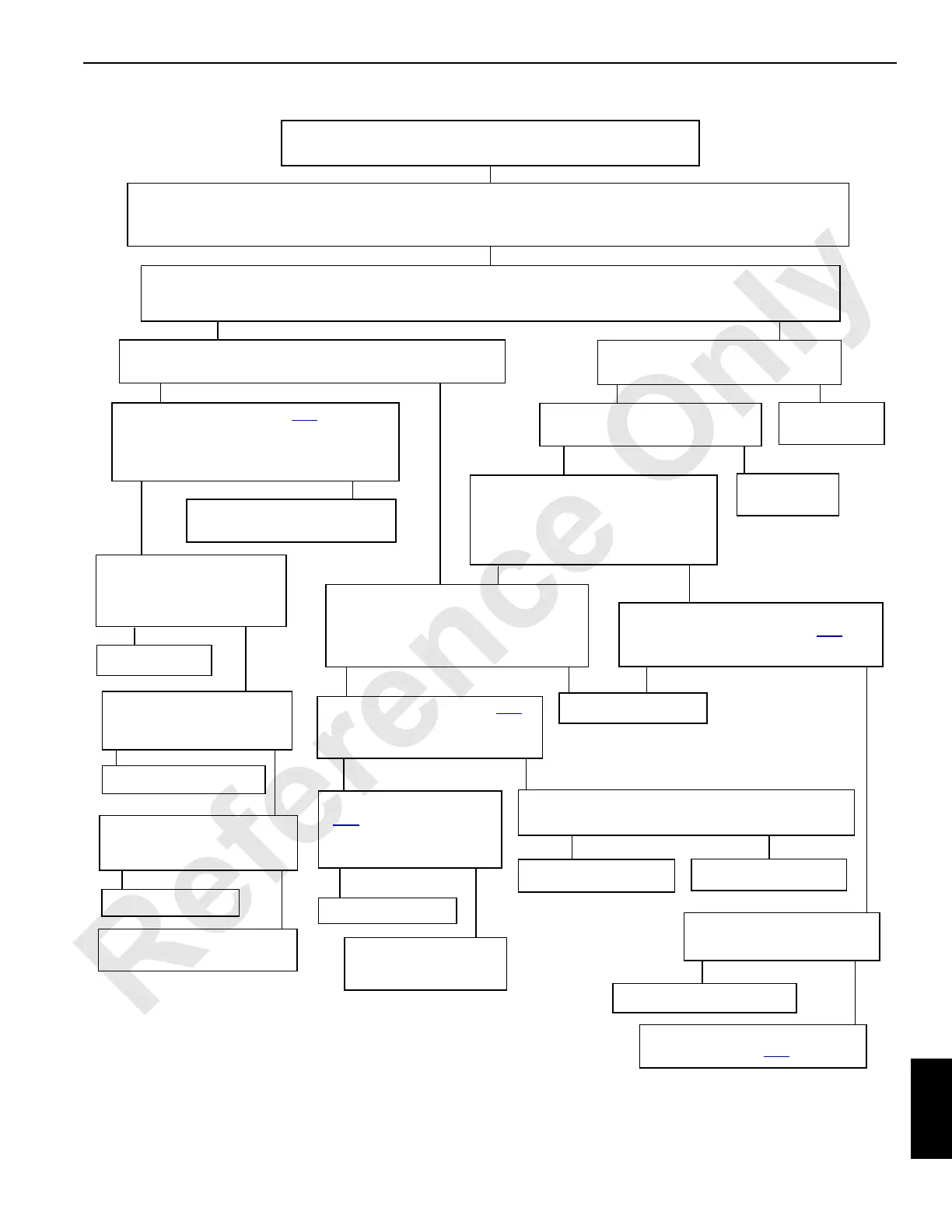

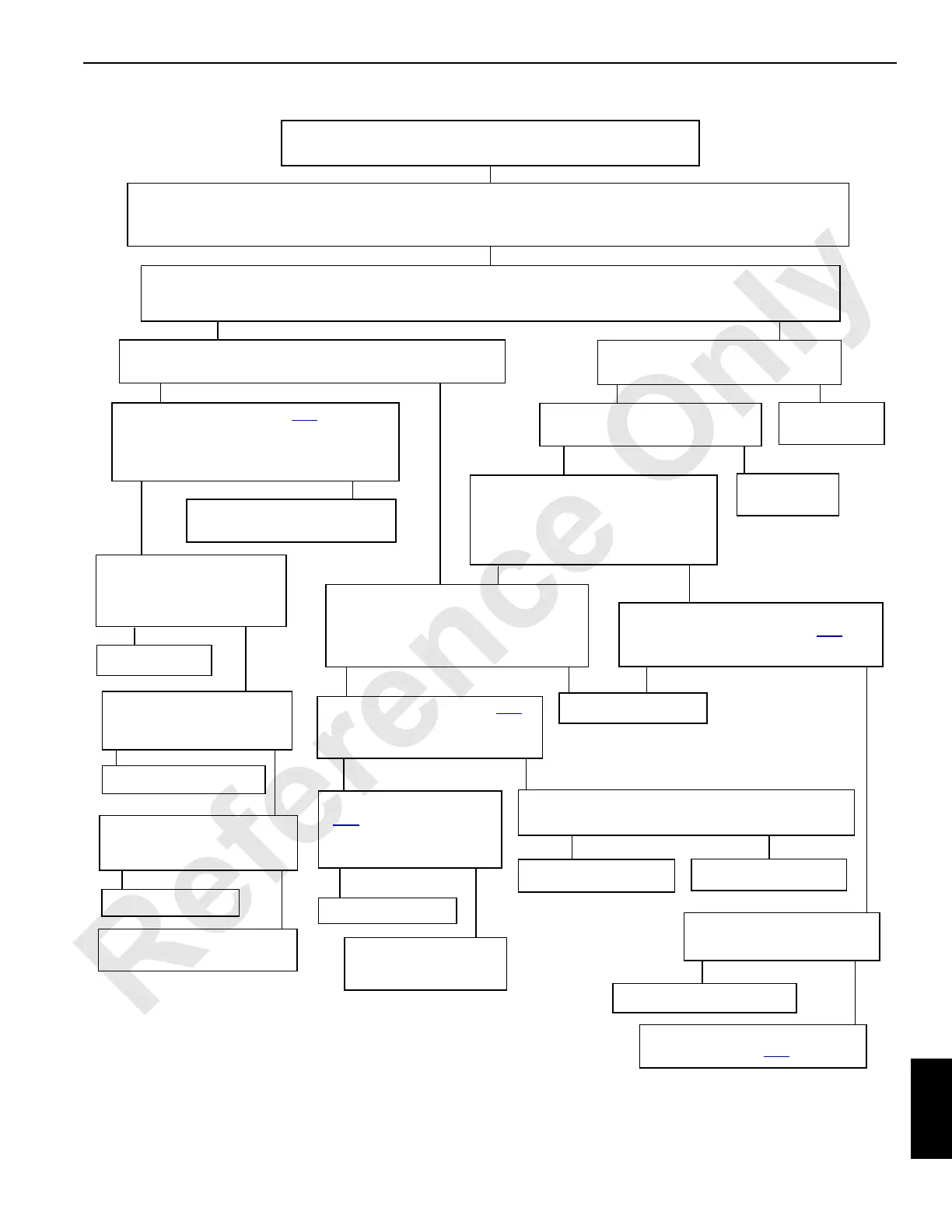

PROBLEM 9

Crawlers will not travel in either direction (one or both tracks).

POSSIBLE CAUSES

Brake valve worn; Control handle worn; EDC bad; No voltage from handle to PC controller; No voltage out of PC controller to pump

EDC; Low brake pressure; Wiring or switch is bad; Pump, motor or gearbox is worn.

CHECKS

Diagnostic display TRACK screen (bank 7) displays 1 when problem handle is moved in problem direction?

Yes No

Engine loads when moving problem handle in either direction?

Is travel brake switch in OFF position?

No

Yes

NoYes

Use test plug adapter. (See Te st

10.) Is 12

volts present at hydraulic brake solenoid

(84E), when problem handle is moved?

No

Yes

Is 12 volts present at brake switch?

Move switch to

OFF position.

Yes No

Repair or replace wiring or switch.

Consult dealer/factory.

When moving problem handle in both

directions, does TRACK diagnostic screen

(banks 1 or 2) obtain 100% handle control

in each direction?

NoYes

Replace switch,

fuse or wiring.

Does track turn while moving

handle and actuating manual

override on brake valve?

No

Yes

When moving problem handle in both

directions, does TRACK diagnostic

screen (banks 3 or 4) obtain 100% pump

control in each direction?

NoYes

Voltage at handle (83P or 84P) is greater

than 0 with handle moved? (See Tes t

13.)

No

Yes

Replace solenoid.

Is pressure at brake more than

300 psi?

No

Yes

Manually stroke pump (See Tes t

11.) Does pump pressurize?

Consult dealer/factory.

NoYes

Repair brake or gear box.

Is system charge pressure more

than 300 psi?

Replace brake valve.

Re-adjust charge pressure

relief or replace pump.

NoYes

Use test plug adapter. (See

Tes t

5.) Is voltage present at

pump EDC?

NoYes

Replace pump EDC.

Repair or replace wiring

or consult dealer/factory.

Isolate pump. Does manually stroked pump pressurize?

Repair or replace motor.

Repair or replace pump.

NoYes

Is 10 volts at handle (87FA)?

No

Yes

Repair or replace handle.

Repair or replace fuse (F16) and/or

wiring. (See Te s t

12.)

Loading...

Loading...