POSSIBLE CAUSES

Faulty relief valve, auxiliary disable valve, proportional control valve or

control valve section; Cylinder failure; Pump is bad.

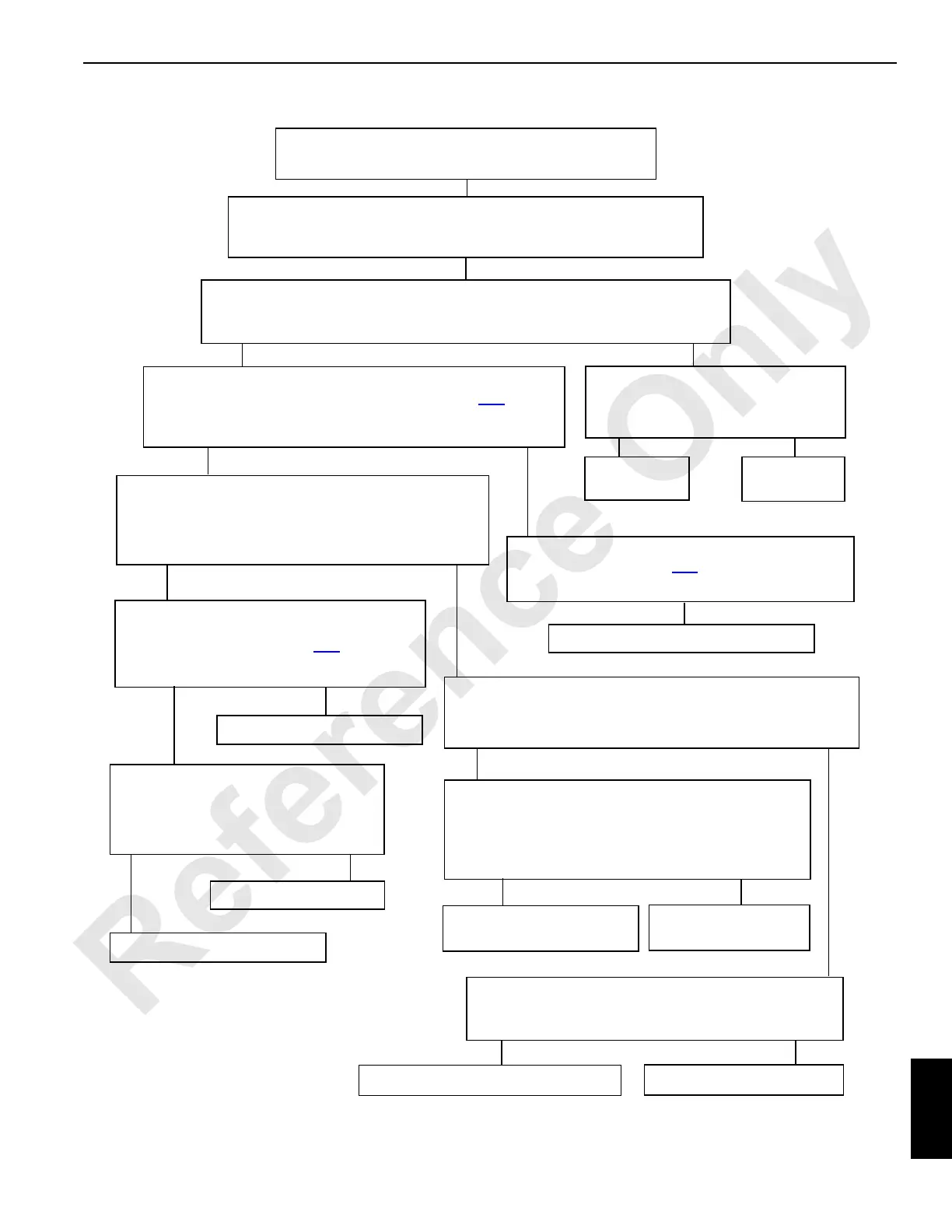

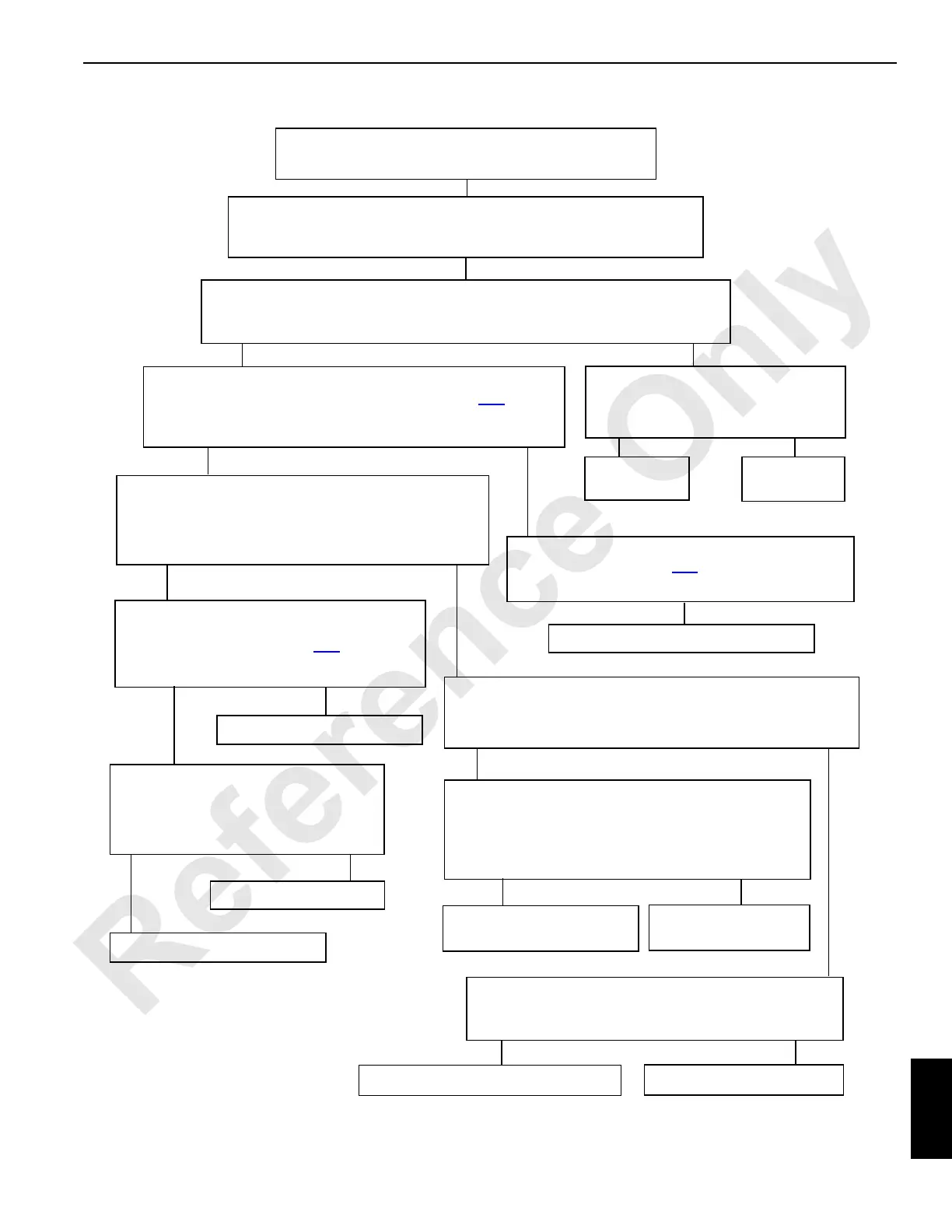

PROBLEM 27

Boom handling cylinders will not extend or retract.

CHECKS

Check for 12 volts at auxiliary disable valve when enabling cylinders.

No Volts12 Volts

Check for 3,500 psi at auxiliary system disable valve while enabling any

upper valve assembly control in retract direction. (See Tes t

25.)

3,500 psi or more

3,500 psi or less

Check diagnostic display screen (bank 3) for

change of 4 when enabling cylinders.

Check disable

valve wiring.

Consult dealer /

factory.

Change

No Change

3,500 psi or less

3,500 psi or more

3,500 psi or less

Check for 3,500 psi at auxiliary system disable valve while

enabling any other adapter frame valve section in retract

direction.

Adjust auxiliary system disable valve and check pressure.

(See Tes t

25.)

Replace auxiliary system disable valve.

Enable boom handling cylinder extend and retract solenoid valves

and check that voltage is present.

Voltage

No Voltage

Disconnect adapter frame valve assembly from proportional

flow control valve and plug valves. Check pressure at

auxiliary system disable valve.

3,500 psi or less

3,500 psi or more

Repair or replace proportional

flow control valve.

Repair or replace adapter

frame control valve.

Check for 12 volts at boom handling cylinder switch wire #55.

Voltage

No Voltage

Replace appropriate diode to wire #89D1.

Replace appropriate switch.

Replace counterbalance valve.

Repair or replace cylinder.

Yes

No

Exchange boom handling counterbalance

valve cartridges. Does problem cylinder

operate when enabled.

Repair or replace valve section.

3,500 psi or more

3,500 psi or less

Check for 3,500 psi at auxiliary system disable valve

while enabling boom handling cylinder control in

retract direction. (See Te s t

25.)

Loading...

Loading...