Crankshaft

Removing

1. R emove the cylidner heads and pushrods.

2. R emove the flywheel and flywheel housing.

3. R emove the fan, fan bearing, oil sump, tim-

ing gear housing and intermediate gear.

4. R emove the oil pump and all pistons and con-

necting r ods.

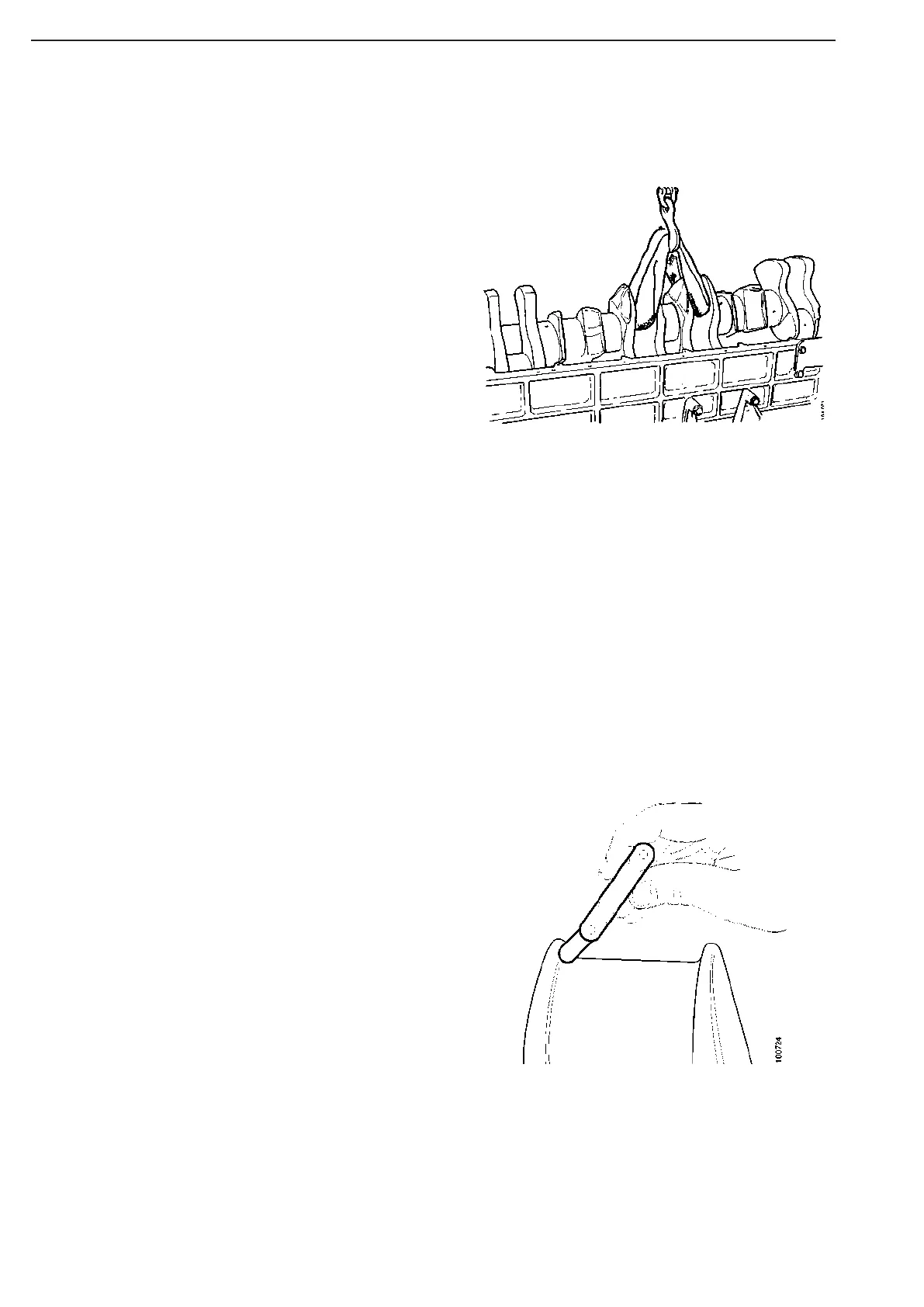

5. R emove al l main bearing caps and carefully

lift out the crankshaft using a lifting strap or

the like which will not damage the shaft jour-

nals.

6. R emove all main bearing halves and thrust

washers on the 7th main bearing.

Checking and grinding

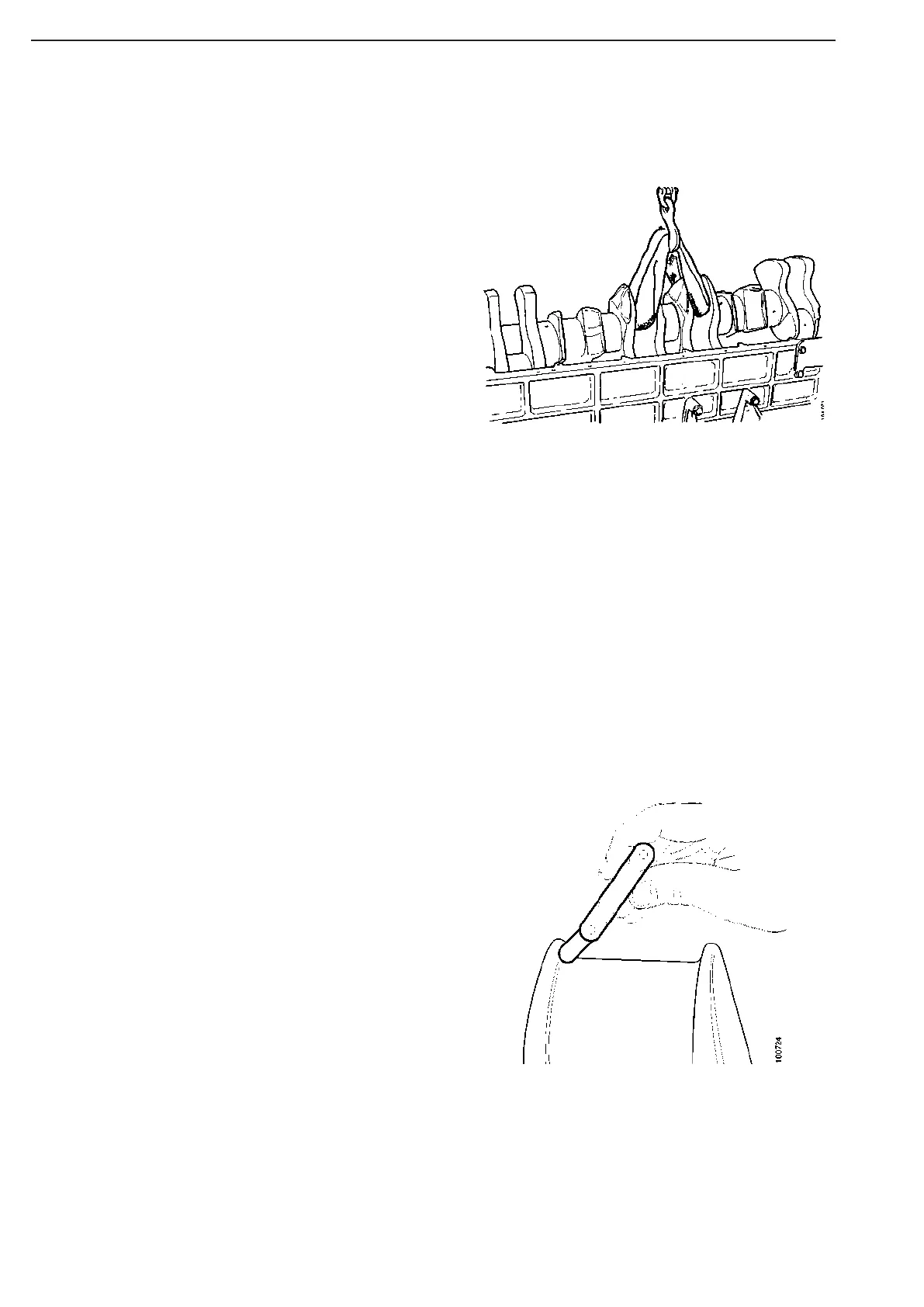

1. Measure the crankshaft pivot pins. Use a

micrometer to take measurements at two

points 90 degrees apart.

If either of these diameters is below the spec-

ified lower limit, regrinding of the crankshaft

or the fitting of a r eplacement crankshaft

should be considered.

The oil pressure should also be taken into

account, which is in turn also affected by

wear in the main and big-end bearings.

2. W hen regrinding, stated undersiz es must be

complied with. T here are bearings adapted to

these dimensions.

It is important that the fillet radius of the

pivot pins is correct.

After grinding the pivot pins, the oil hole ori-

fices at the bearing surfaces should be

rounded and polished.

Loading...

Loading...