Subject to modifications

User Manual

Operation Instructions

2.1A-30008-A04

Page 13 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Pump elements with fixed lubrication output, continuation

Check valve

1164b95

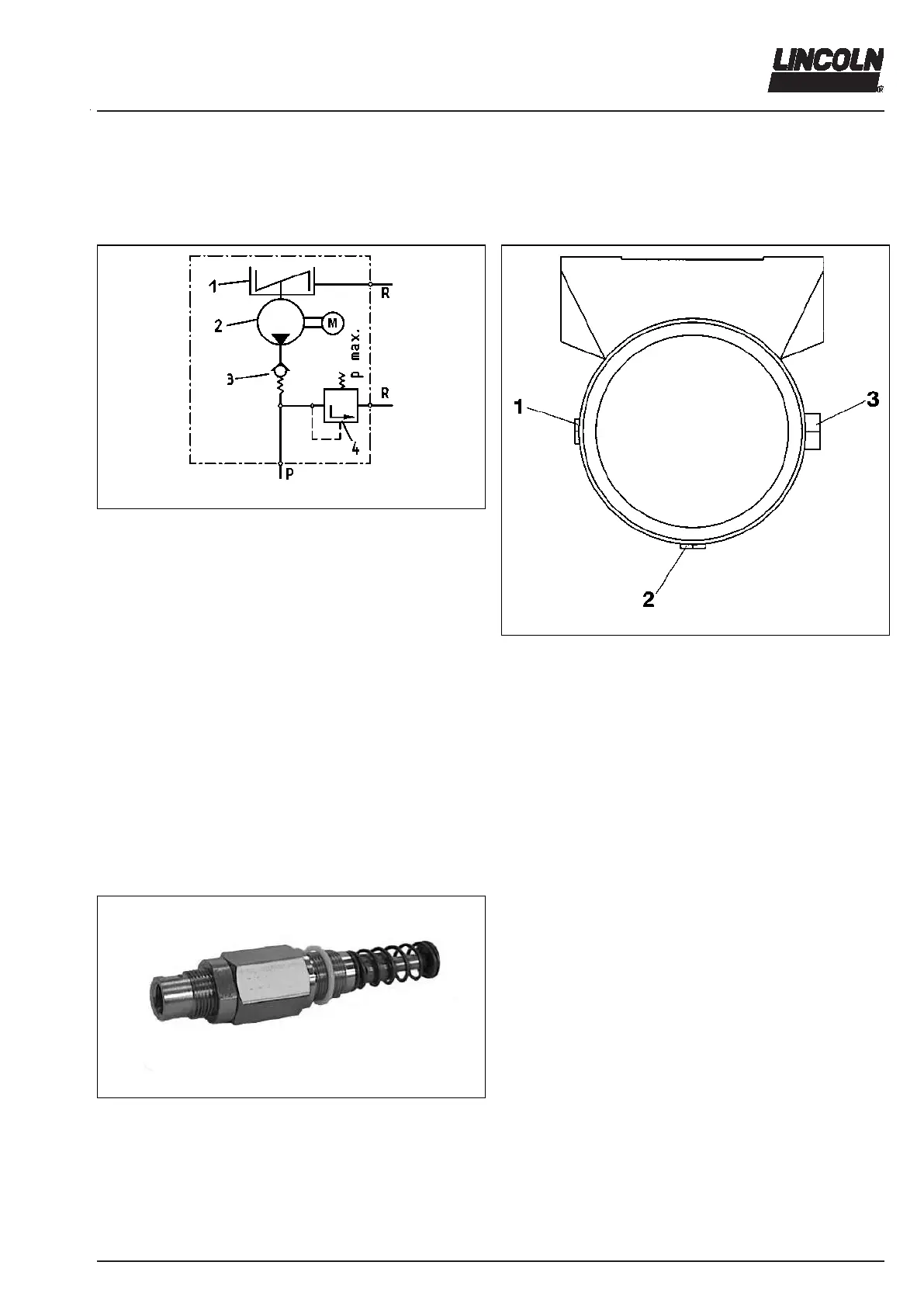

Fig. 11 Hydraulic diagram of the pump

1 - Reservoir with stirring paddle

2 - Pump

3 - Check valve, spring-loaded

4 - Pressure relief valve

R - Return line

p - Pressure line

The check valve

- closes the pressure line during suction stroke.

- prevents the lubricant from flowing back to the housing

or reservoir.

Arrangement of the pump elements

1163a95

Fig. 12 Arrangement of the pump elements

If several pump elements are to be installed, the installa-

tion arrangement shown in Fig. 12 must be adhered to.

If there is only one pump element, it can be installed in

any position. Standard position is no. 3.

If there are two elements, install one in position 3 and the

other in position 1.

Pump elements with adjustable lubricant output

4158a99

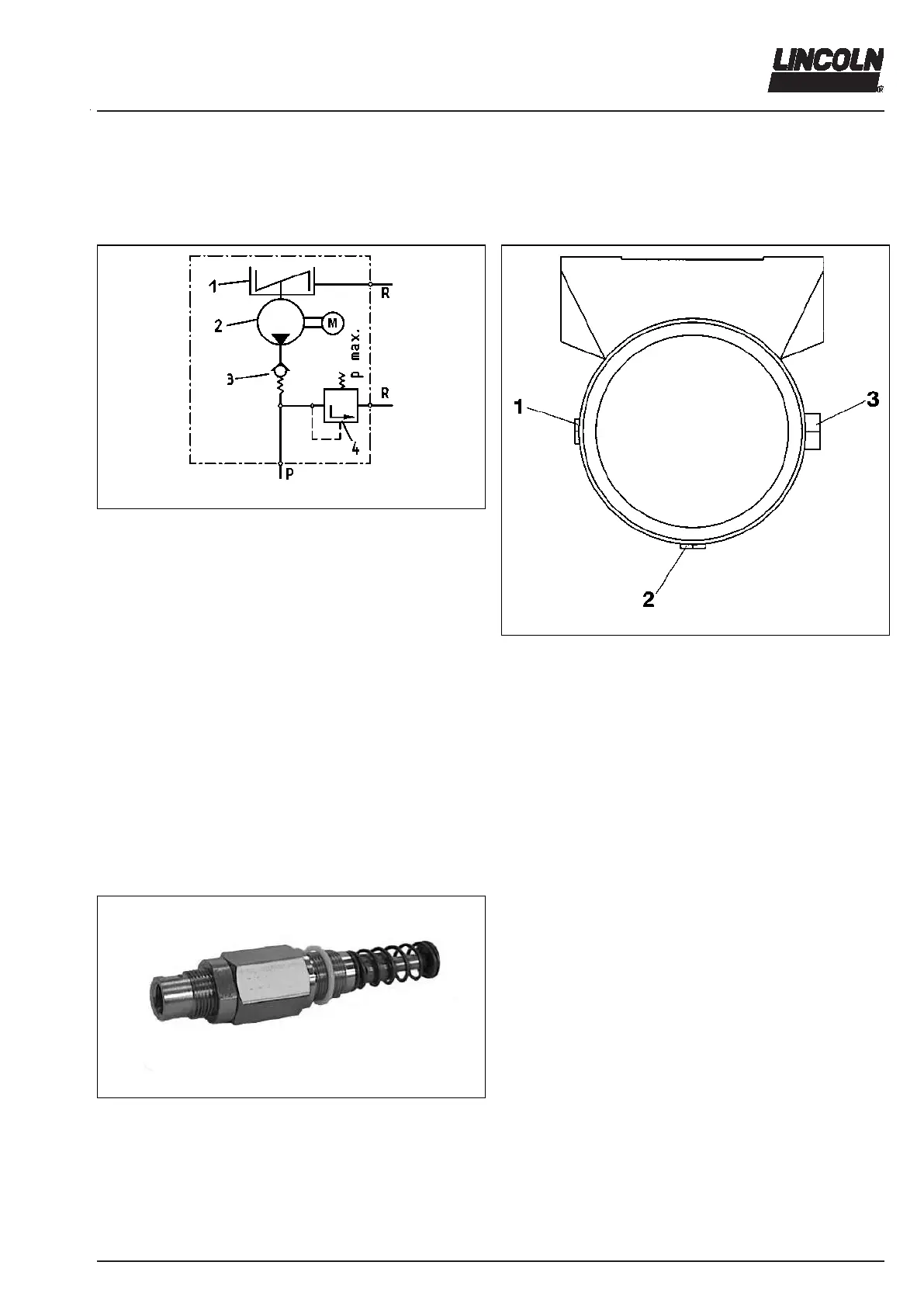

Fig. 13 Adjustable pump element

The mode of operation (suction and supply phase) is the

same as that of the pump elements with an invariable lu-

bricant output.

Lubricant outputs are adjustable from 0.04 to

0.18m

3

/stroke, or 0.7 to 3cm

3

/min.

The pump elements are factory-set to the maximum lubri-

cant output; the adjusting dimensions “S” should be

29 ± 0.1 mm (see fig. 14, page 14).

Loading...

Loading...