SHOP MANUAL MT26/31 - 12.2004SHOP MANUAL MT26/31 - 12.2004

GENERAL

CH 0 PAGE 16 CH 0 PAGE 17

GENERAL

SHOP MANUAL MT26/31 - 12.2004SHOP MANUAL MT26/31 - 12.2004

GENERAL

CH 0 PAGE 16 CH 0 PAGE 17

GENERAL

Apply thread locking (see table for sealing/locking

compounds) to important bolts. Prior to coating with sealing or locking compound, wash the bolt with light oil/

trichlorethylene or other fluid recommended by the manufacturer.

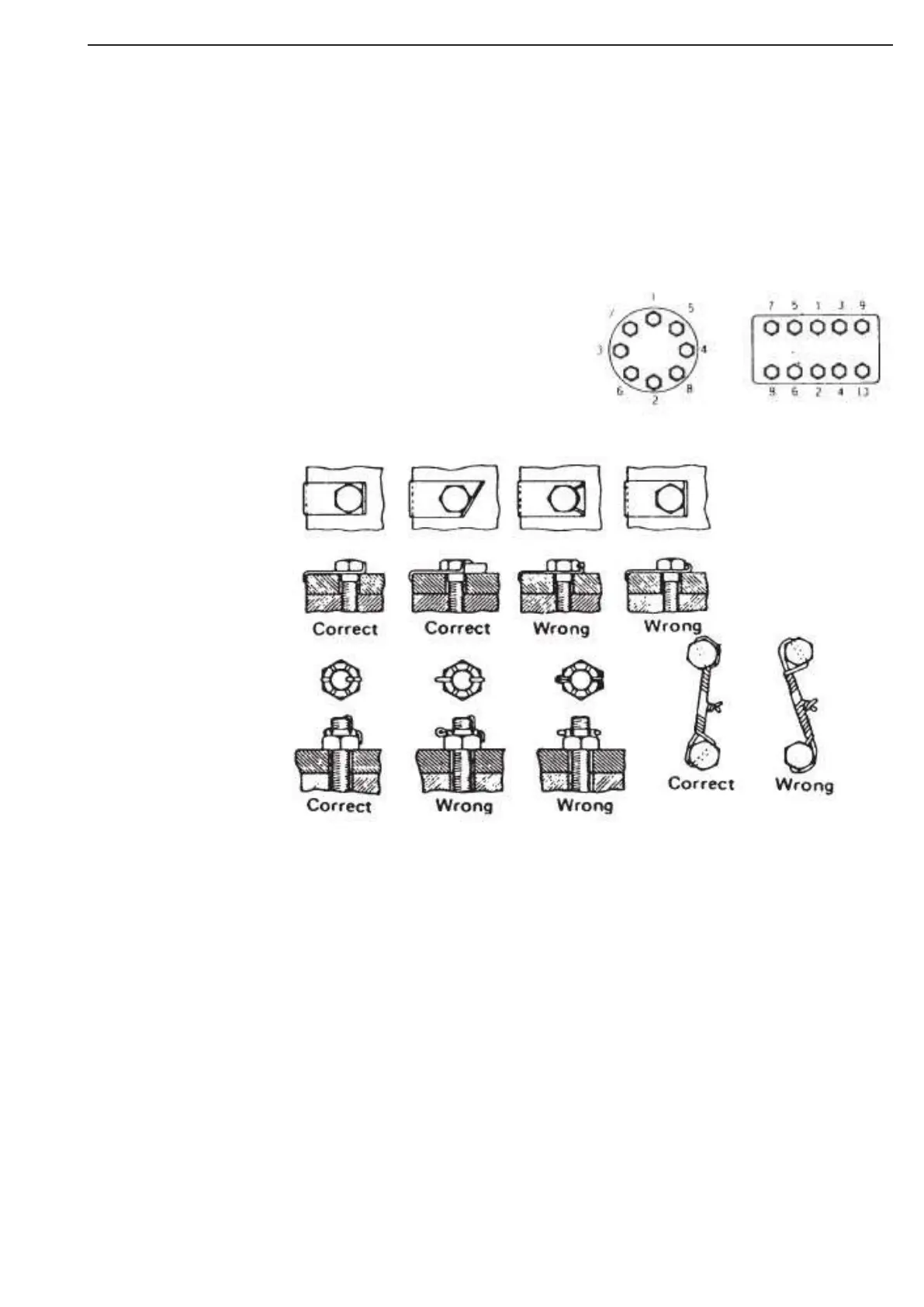

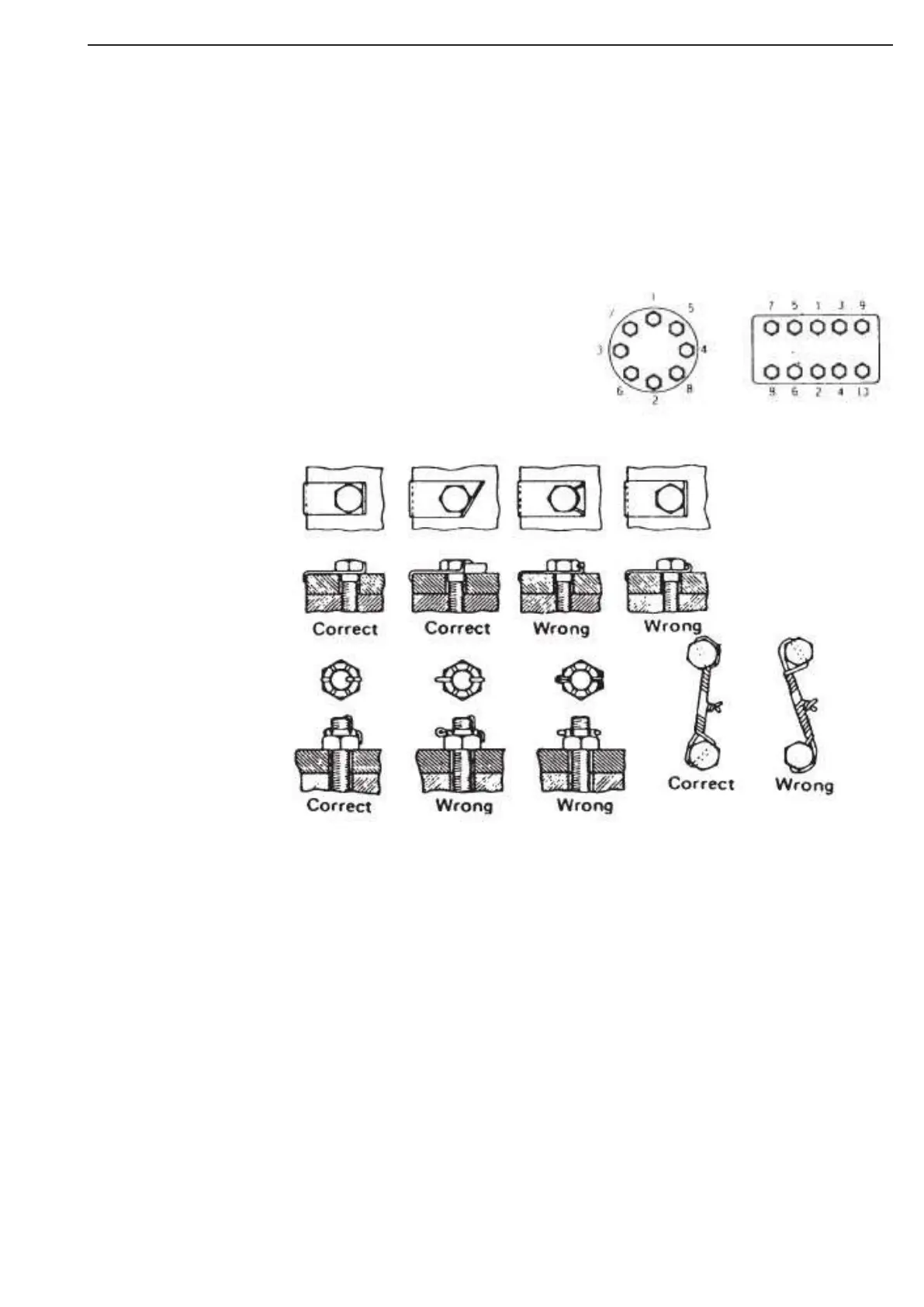

Tighten bolts in the prescribed sequence figures evenly to the specified torque.

• Be careful not to tighten bolts excessively. See next page for recommended values!

• Be sure to align match marks if provided.

• Keep the working area, tools, worker’s hands,

etc. clean during assembly operation.

• Coat the surfaces of parts to be press-fitted wit

Molykote grease.

Loctite 242/243 ........................ Middle strength (for locking of screws, bolts and nuts).

Loctite 270/2701 ...................... High strength (for locking of screws, bolts and nuts).

Tree bond 1374..........................High strength (for locking of screws, bolts and nuts).

Loctite 603 ............................... High strength (for locking of bearings bushings, etc.).

Loctite 638 ............................... Extra high strength (for locking of bearings, bushings, etc.).

Loctite 574 ............................... Master gasket as liquid gasket.

Loctite 7063 ............................. For cleaning of surfaces prior to lubrication or gluing.

Molycote 321R*:........................Anti-obstruction and running-in lubricant.

Würth 210/Loctite 8201 ............Anti-corrosion spray for electrical wires and components.

0.2.19.1 Types of sealing-/locking Compounds

and Lubricants used during Assembly

Loading...

Loading...