Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655-

Ch 1 page 121

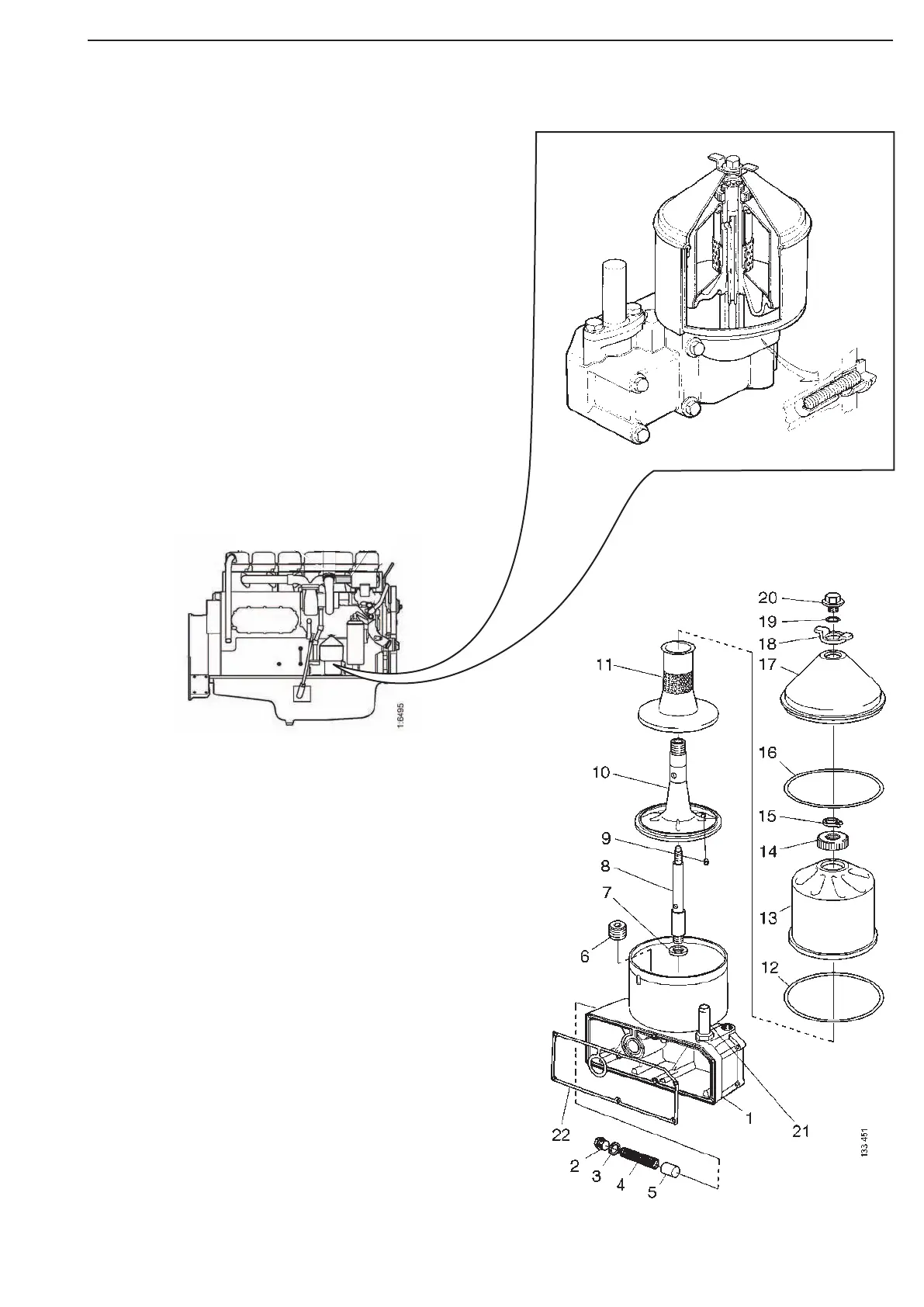

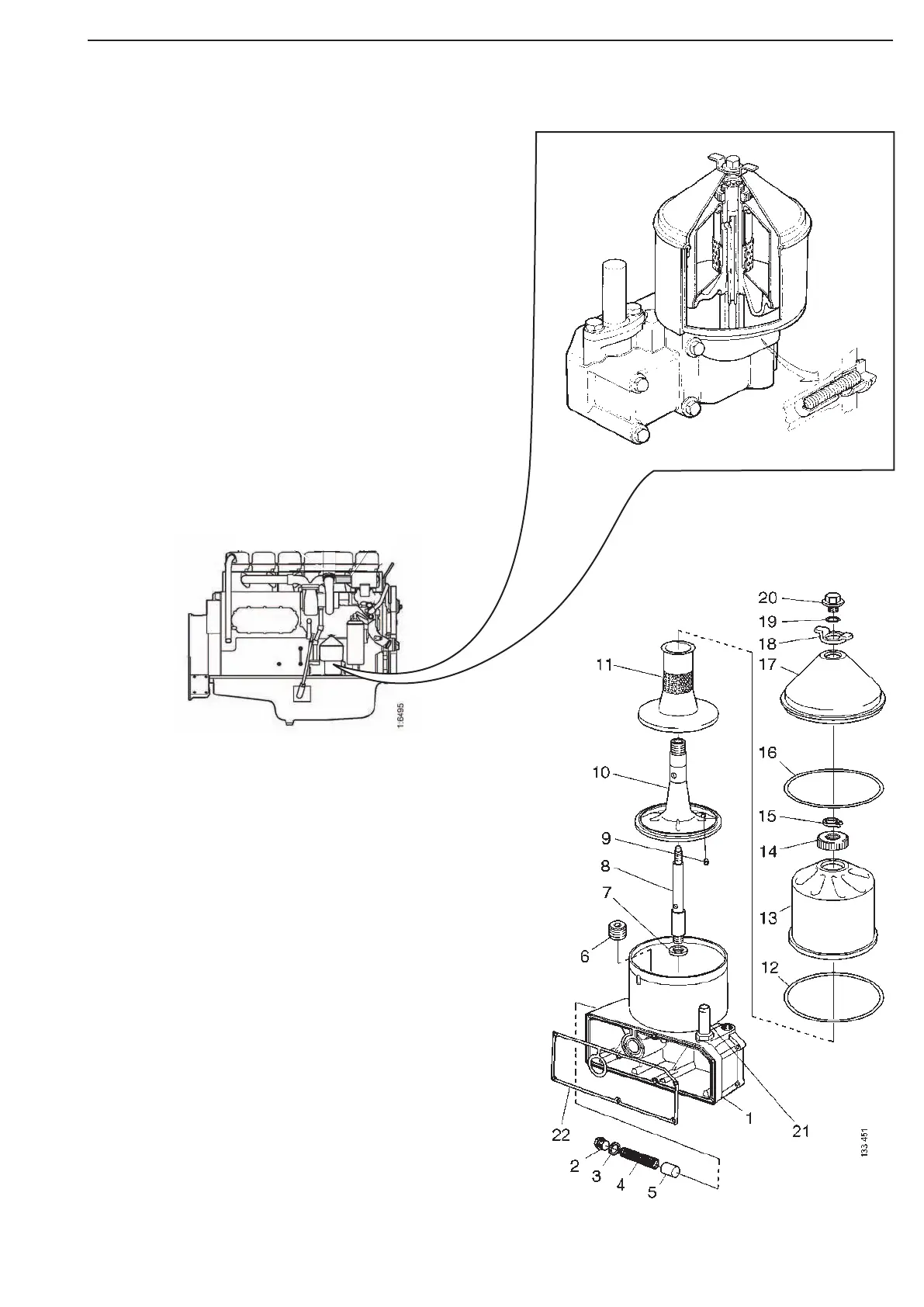

Some of the oil passes from the main passage

in the oil cooler cover to the centrifugal cleaner

and then, after cleaning, flows back to the sump.

Surplus oil is drained back to the sump via an

overflow valve. This ensures that the pressure in

the oil system is not too high.

The centrifugal cleaner’s rotor is caused to spin

by the force of the oil which squirts out through

two nozzles at the bottom of the rotor.

Dirt particles are slung against the wall of the

rotor by centrifugal force and fasten there as a

coating.

The rotor should be dismantled and cleaned at

definite intervals according to the inspection pro-

gramme included in the operator’s manual.

Centrifugal oil cleaner

1. Housing

2. Plug

3. Gasket

4. Spring

5. Piston

6. Plug

7. Washer

8.Shaft

9. Nozzle

10. Rotor

11. Strainer

12. O-ring (change when cleaning)

13. Rotorbowl

14. Nut

15. Snap ring

16. O-ring (change when cleaning)

17. Cover

18. Lifting eye

19. O-ring

20. Lock nut

21. Nipple

22. Gasket

DC12 50

A 04 P

6510525

6 510 525

Loading...

Loading...