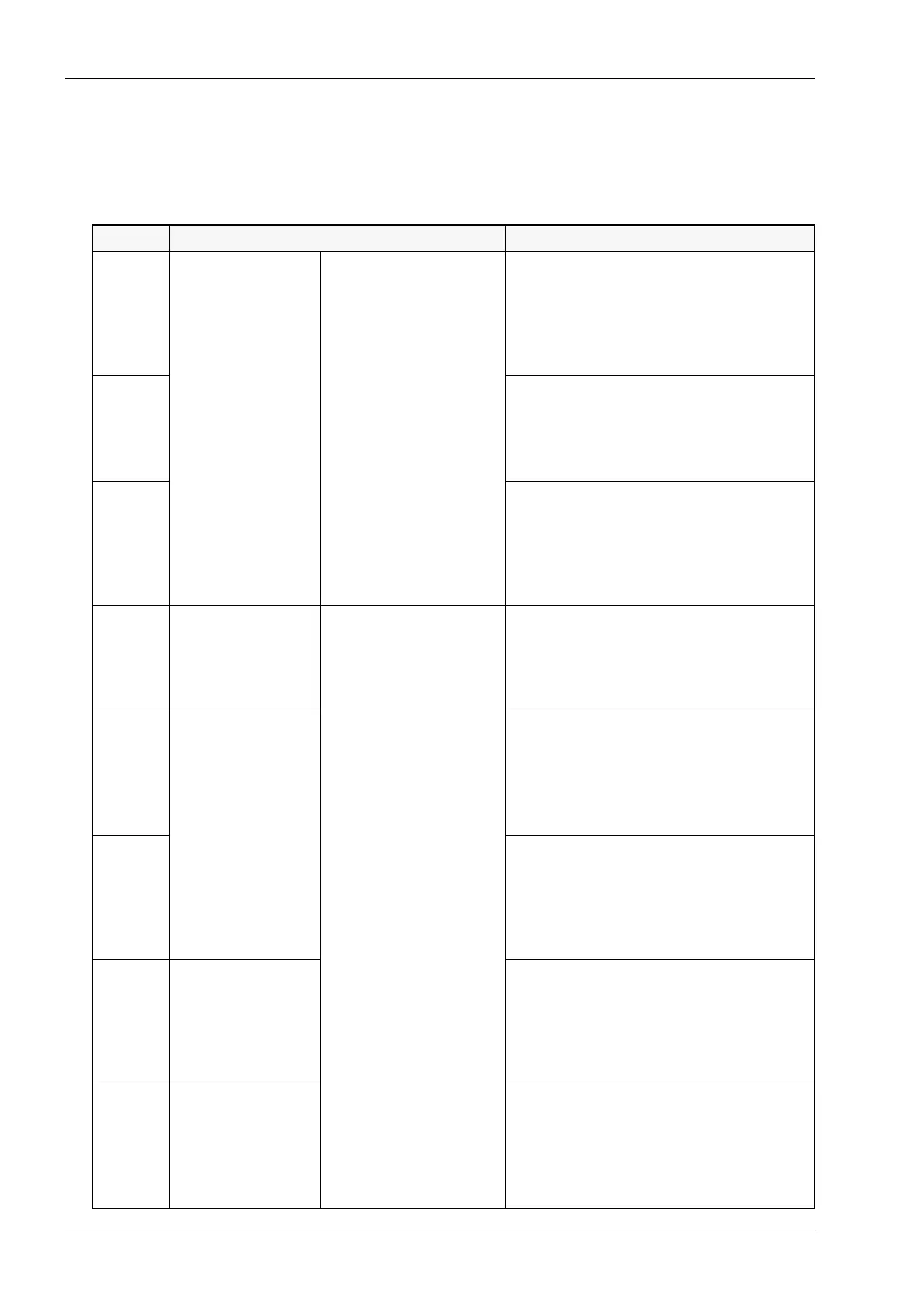

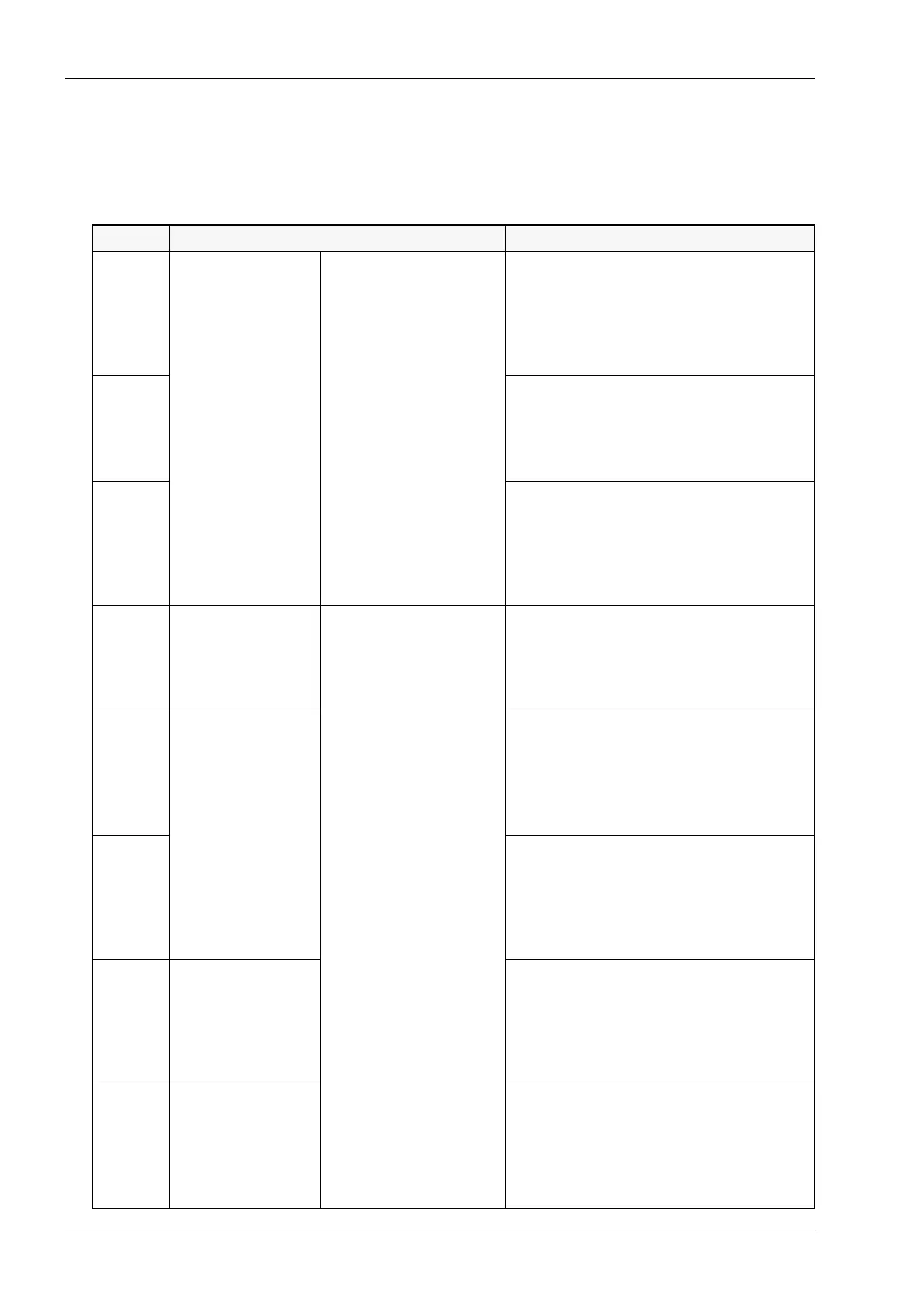

1 ERROR MESSAGES Chapter C: ERROR MESSAGES

76 Planmeca ProOne Technical manual

1 ERROR MESSAGES

1.1 Motorized motion related (E02-XXX)

Code Explanation Comments

E02-004 Lift motor Drive current Overcurrent (> 3.5 A) detected in the lift

motor upwards movement.

The movement has been stopped. Check

that the upwards movement is not

prevented. Then check the lift motor cable.

If necessary, then replace the CPU PCB.

E02-005 Overcurrent (> 2 A) detected in the lift motor

downwards movement.

The movement has been stopped. Check

the lift motor cable. If necessary, then

replace the CPU PCB.

E02-006 Undercurrent (< 0.3 A) detected in the lift

motor.

Too low current detected in the lift motor

and the column cannot be moved. Check

the lift motor cable. If necessary, then

replace the CPU PCB.

E02-007 Linear motor Timeout Timeout at linear motor.

Check that the mechanism is not stuck.

Then check the linear motor start limit

sensor and cable. If necessary, then

replace the CPU PCB.

E02-008 Temple support

motor

Timeout at temple support motor (open limit

sensor).

Check that the mechanism is not stuck.

Then check the temple support motor open

limit sensor and cable. If necessary, then

replace the CPU PCB.

E02-009 Timeout at temple support motor (close limit

sensor).

Check that the mechanism is not stuck.

Then check the temple support motor close

limit sensor and cable. If necessary, then

replace the CPU PCB.

E02-010 Rotation

motor

Timeout at rotation motor.

Check that the mechanism is not stuck.

Then check the rotation motor limit 1 and

limit 2 sensors and cables. If necessary,

then replace the PSU assembly and

perform the filament definition again.

E02-011 Collimator

motor

Timeout at collimator motor.

Check that the mechanism is not stuck.

Then check the collimator motor start limit

sensor and cable. If necessary, then

replace the PSU assembly and perform the

filament definition again.

Loading...

Loading...