4-40 ECODRIVE03 DKC**.040, DKC**.100, DKC**.200 ECODRIVE03 Drive Controllers

4.2 Electrical connections - independent of the drive

controller type

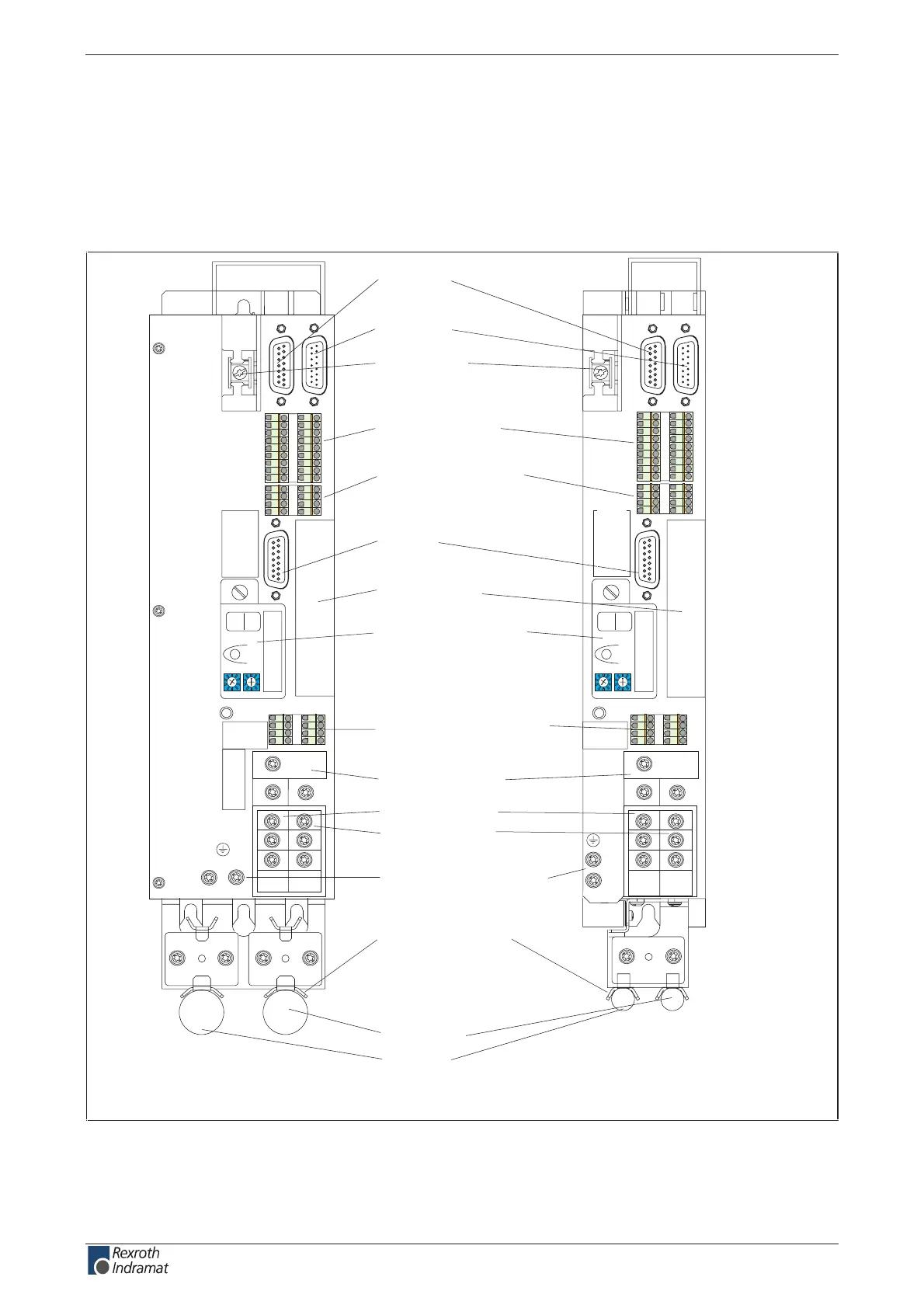

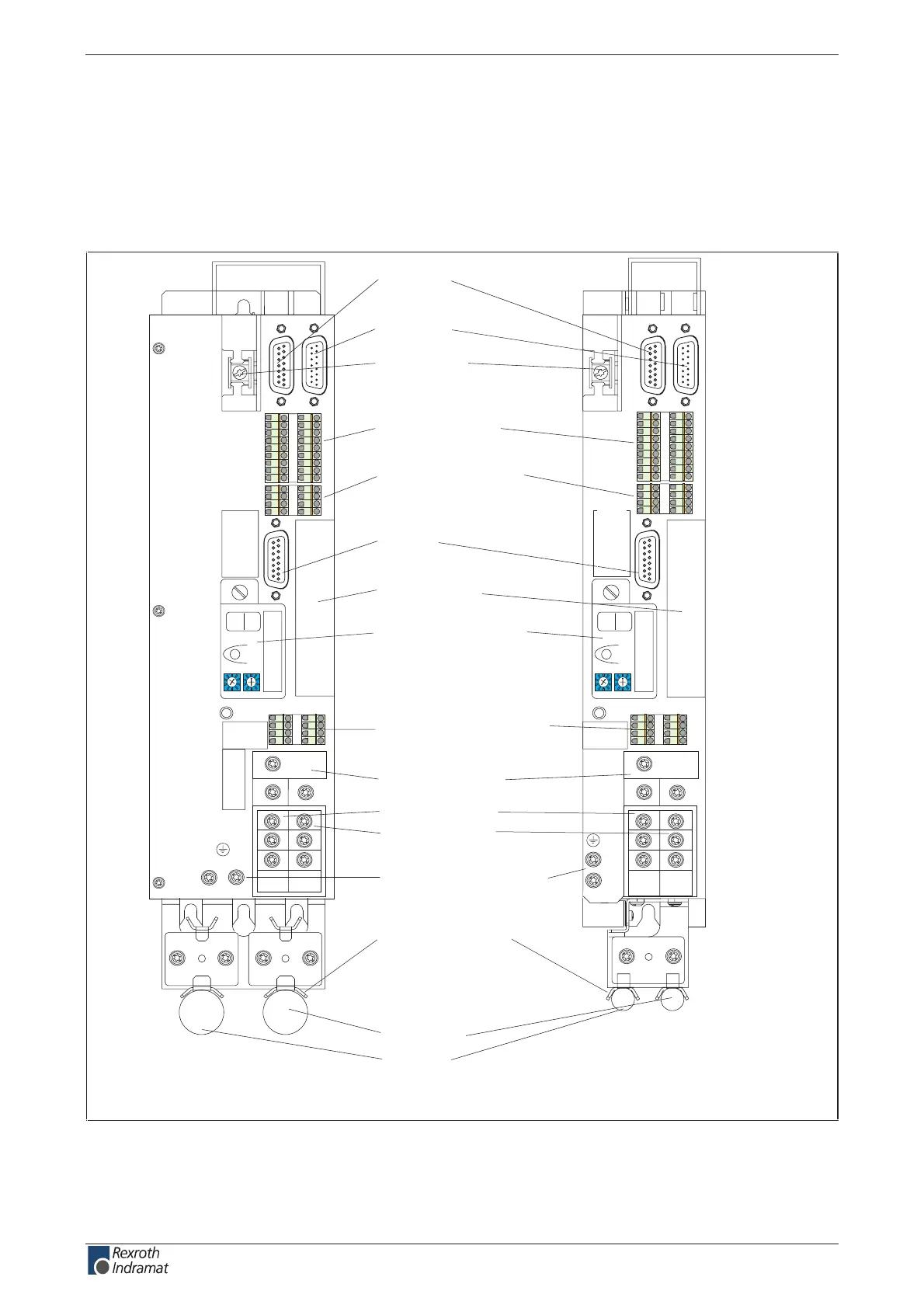

A look at the drive controller and connector designations

Front view

X3:

digital and analog

in-/ outputs

X1:

control voltage supply

and control signals

X2:

RS232/

RS485

X6:

motor temperature monitoring

holding brake

X5:

DC bus connection

mains connection

motor connection

X4:

encoder 1

X8:

encoder 2

DKC**.3-100-7-FW

DKC**.3-040-7-FW

FA5026f1.fh7

motor cable

line input

Barcode

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

H1

S1

S3 S2

Barcode

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

H1

S1

S3 S2

Barcode

Typenschild

Barcode

Typenschild

123 4 5 6 7 8 9 1 2 3 4

10 1112 131415161718

5 6 7 8

123 4 5 6 7 8 9 1 2 3 4

11121314 15161718

5 6 7 8

123 4

567 8

123 4

567 8

XE2

XE1

XE1XE2

XS1:

cable clamp

shield connections

- complete shield motor cable

- holding brake

- motor temp. monitoring

L+

L-

L1

L2

L3

A1

A2

A3

L+

L-

L1

L2

L3

A1

A2

A3

XS2:

cable clamp

shield connections

device-typical

interface

X7:

programming module

(rmware, parameter)

H1 - diagnosis indicator

S1 - fault clearance button

S2, S3 - adress switch

XE1: protective conductor

connection (motor)

XE2: protective conductor

connection (mains)

Fig. 4-43: Front view DKC**.3-040-7-FW and DKC**.3-100-7-FW with

Connectors

customerservice@hyperdynesystems.com | (479) 422-0390

Loading...

Loading...