ECODRIVE03 Drive Controllers ECODRIVE03 DKC**.040, DKC**.100, DKC**.200 4-45

X1, Connections for Control voltage

Technical description of connector

Ap5264f1.FH7

123 4

567 8

Fig. 4-48: Connector X1

Type No. of pins Design

Spring contact 2 x 4 Bushing on connector

Fig. 4-49: Design

Cross section

single wire

[mm ²]

Cross section

multi core wire

[mm ²]

Cross section

in AWG

Gauge no.:

0,2-2,5 1,5-2,5 16-12

Fig. 4-50: Connection cross section

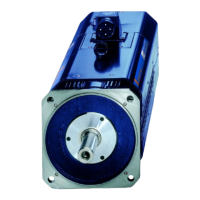

24V control voltage supply (+24V and 0V)

AP5121F1.FH7

+24V

+24V

0V

0V

X1

2

1

3

4

5

8

7

6

device-external device-internal

connection for control voltage

connection for control voltage to additional DKCs

Fig. 4-51: Connections for control voltage

Ap5139f1.fh7

X1

X1

123 4

567 8

24V

123 4

567 8

to additional

devices

Fig. 4-52: Looping through control voltage

Example for application: see page 16-6.

Voltage at X1/1 against X1/2:

Current or power consumption X1/1:

See page 4-13

"Control voltage connection for

DKC"

egnar egatlov dewolla aiV:noitcetorp egatlov esreveR

using internal protection

diodes

Max. allowed current load when looping

through the control voltage via X1.1/2 to

X1.5/6:

DC 10 A

Technical data for control voltage supply: see page 4-13 Control voltage

connection for DKC.

Illustration:

Design:

Connection cross section:

Connection

+24V and 0V:

Connection loads

+24V and 0V:

customerservice@hyperdynesystems.com | (479) 422-0390

Loading...

Loading...