ID Sensor Error Analysis (SP2-221)

The image quality may become very bad when the ID sensor does not operate properly. However, there

is no such SC code that indicates ID-sensor malfunction; instead, SP2-221 shows you some information

on the ID sensor. Check this information when the image quality is not very good.

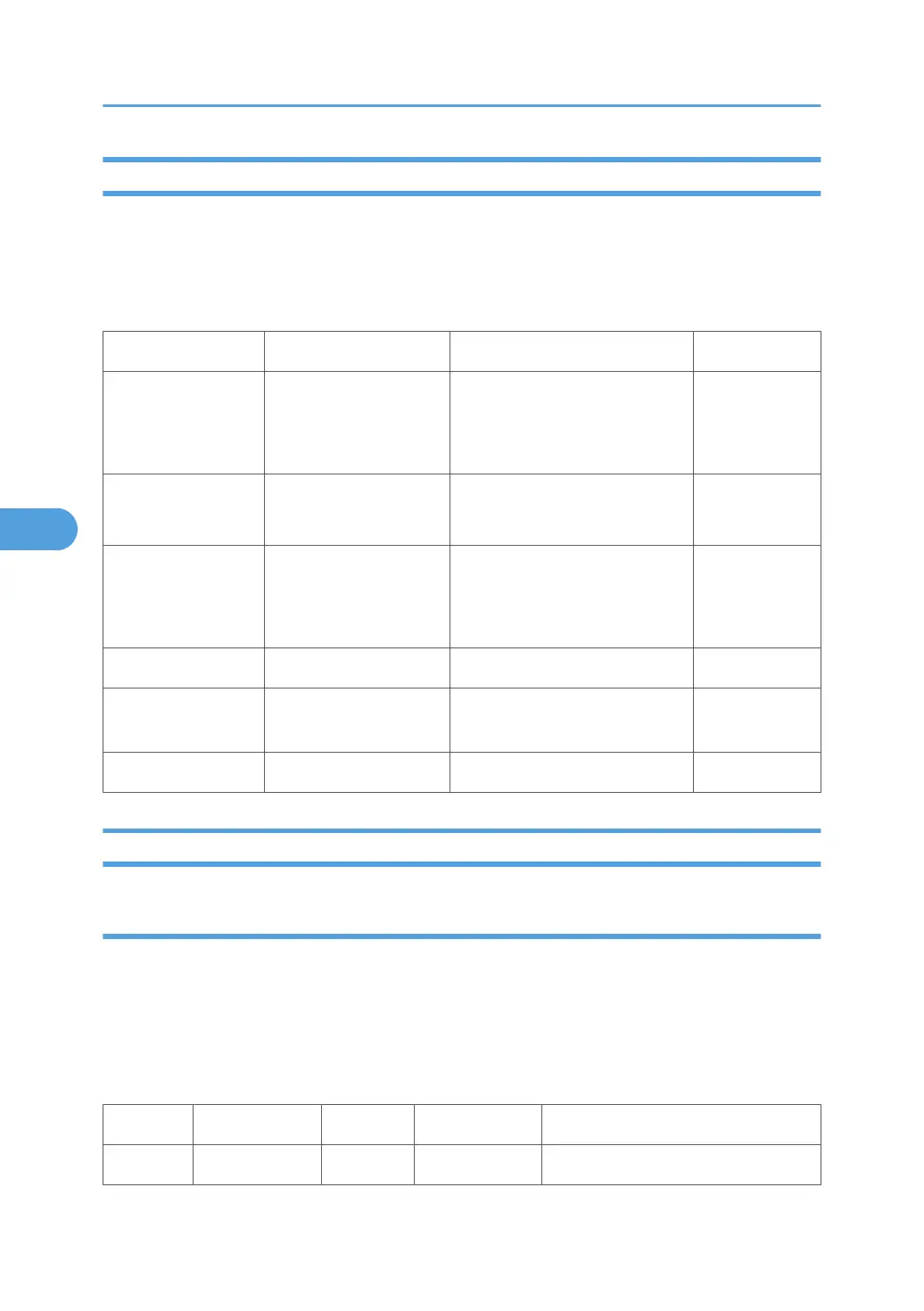

The table lists the information shown with SP2-221 (ID Sensor Error Analysis).

SP Error condition Possible cause Remarks

SP2-221-1 Vsg

(VG in the display)

Vsg < 2.5V or

(Vsg – Vsp) < 1.00V

• ID sensor defective

• ID sensor dirty

• Drum not charged

-

SP2-221-2 Vsp

(VP in the display)

Vsp > 2.5V or

(Vsg – Vsp) < 1.00V

• Toner density very low

• ID sensor pattern not created

-

SP2-221-3 Power

(PW in the display)

Vsg < 3.5V

when maximum power

(979) is applied

• ID sensor defective

• ID sensor dirty

• Drum not get charged

Power source

for the ID-sensor

light

SP2-221-4 Vsdp No Error Conditions -

SP2-221-5 Vt

Vt > 4.5V or

Vt < 0.2V

• TD sensor defective -

SP2-221-6 Vts - - -

Memory Clear

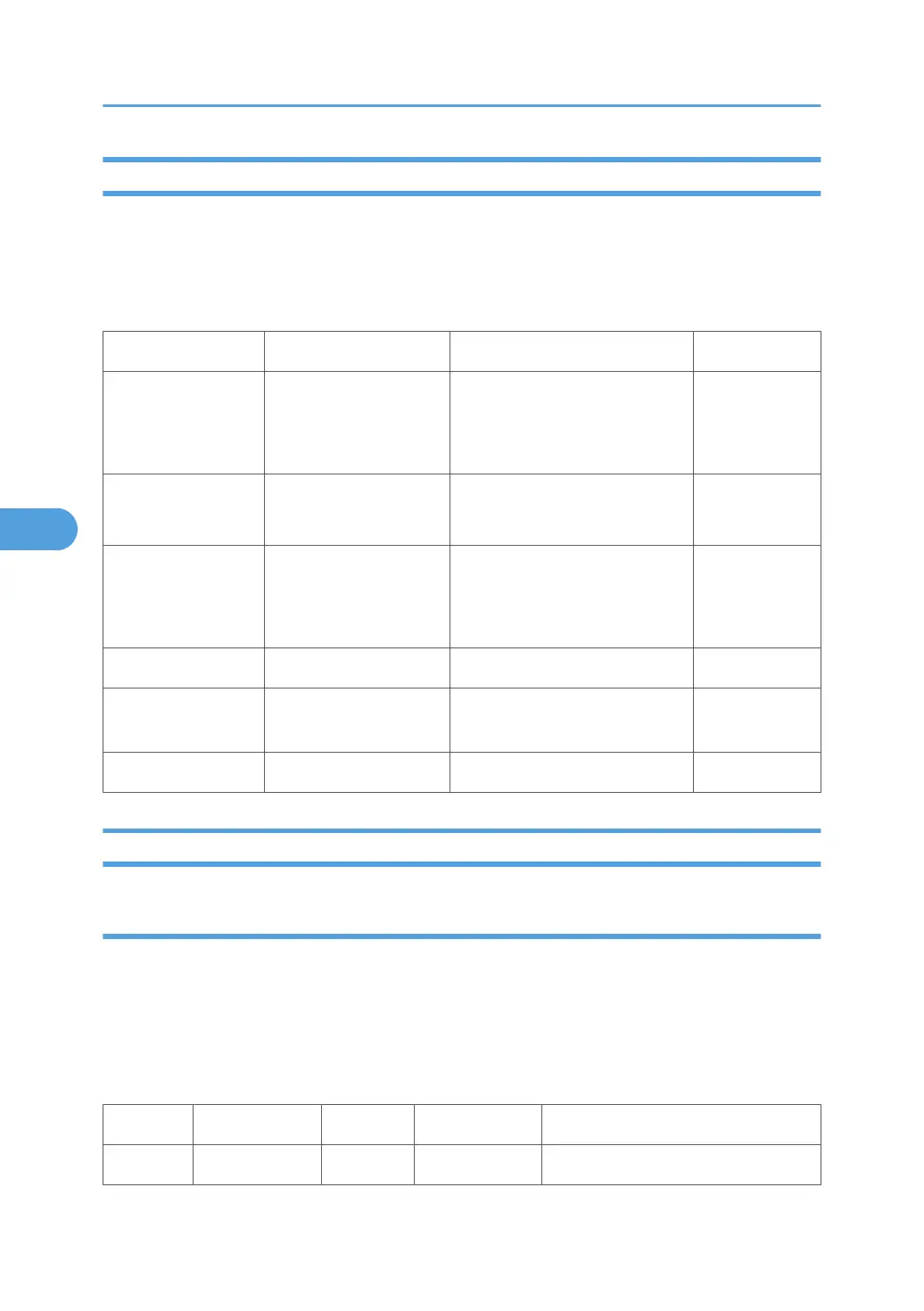

GW Machine

The GW machine (the machine with the optional controller box) stores the engine data in the NVRAM on

the BICU, and stores the other data in the NVRAM on the optional controller. To distinguish between the

engine data and the other data, see SP5-801-003 through 015. This service program (SP5-801) handles

the controller data. Any data that is not handled by SP5-801 is the engine data. The data in the BICU

NVRAM (engine data) is cleared by SP5-998-001 while the data in the controller NVRAM (controller

data) is cleared by SP5-801-xxx (for exceptions, see "Exceptions" as described below).

Machine Data NVRAM Cleared by Remarks

GW

Engine data BICU SP5-998-001 Any data other than controller data

5. Service Tables

218

Loading...

Loading...