• Correction can be disabled with SP2-927.

How Correction is Made

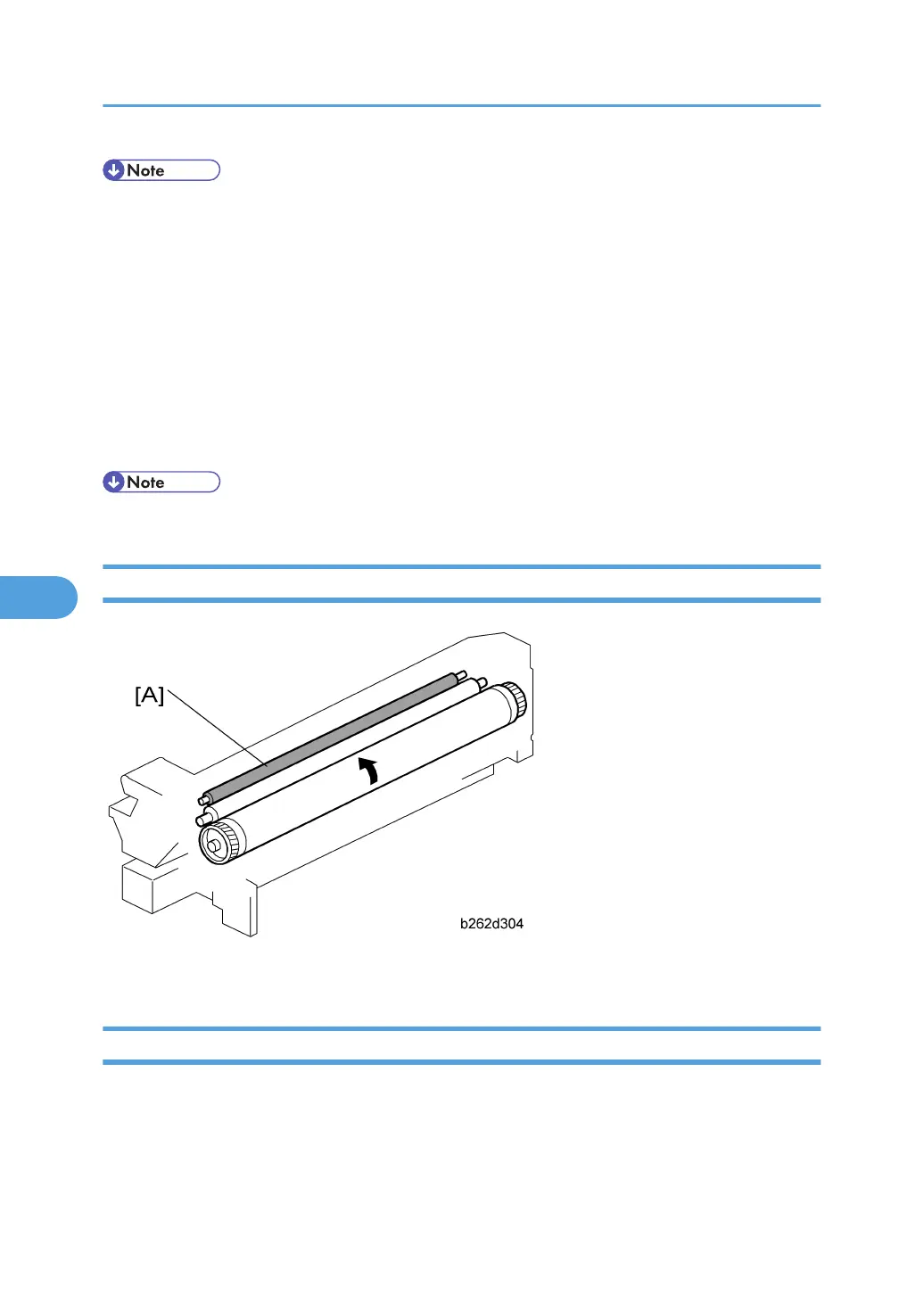

Immediately after creating the ID sensor pattern [A] used for toner density control (* "Toner Density

Control"), the machine generates another pattern [B] for charge voltage correction by intensifying the

development bias (* "Development Bias") to –600 V. The laser remains off, but a small amount of toner

moves to the drum because of the slight charge difference between the drum and development roller. The

ID measures the pattern's density (Vsdp) and the bare drum voltage (Vsg); the FCU compares the difference

and adjusts the roller voltage accordingly.

• If Vsdp/Vsg > 0.95: Change charge roller voltage by +50 V (less negative).

• If Vsdp/Vsg < 0.90 = Change charge roller voltage by –50 V (more negative).

• The current ID sensor readings can be viewed using SP2-221.

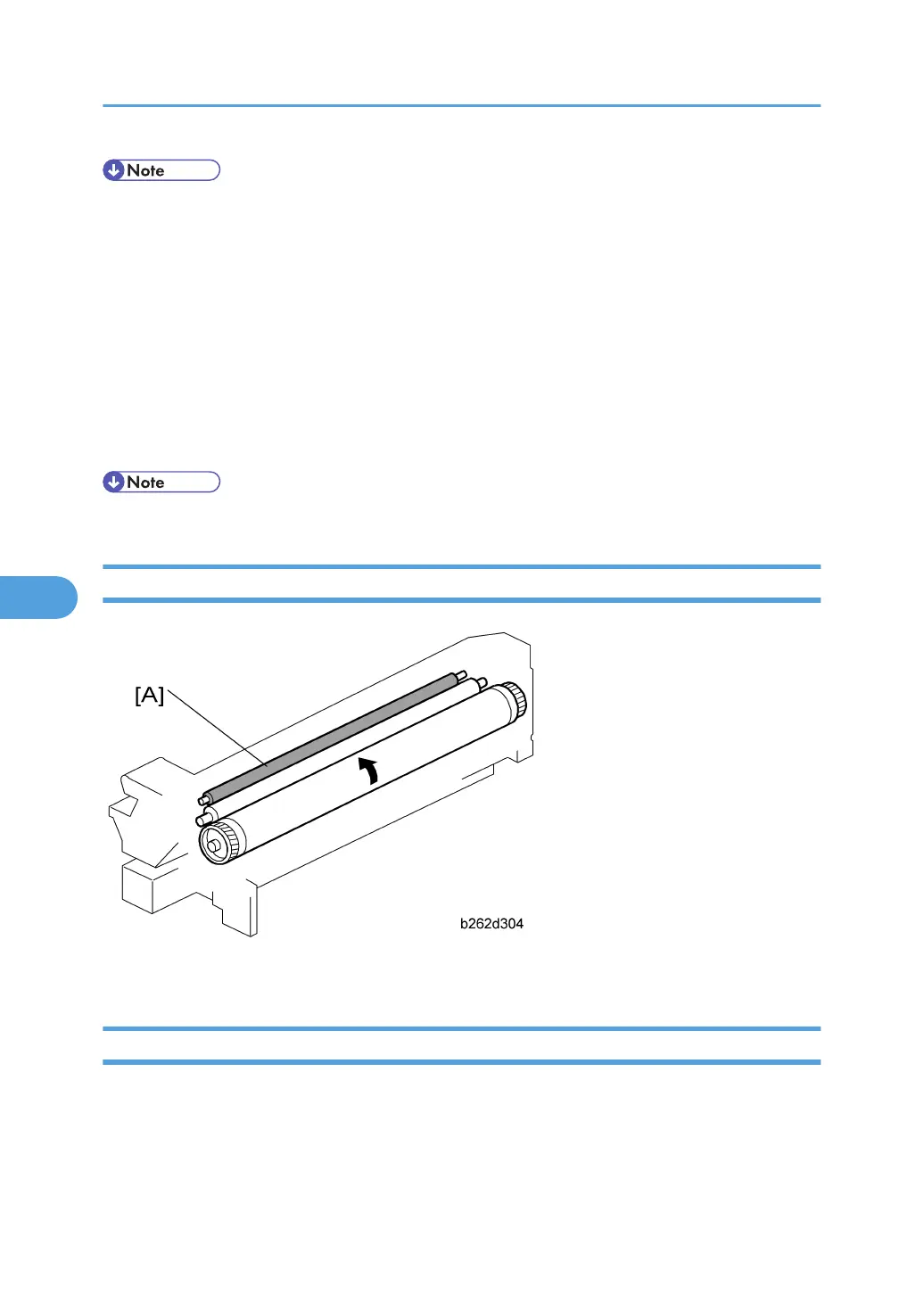

Charge Roller Cleaning

A cleaning roller [A] removes toner and debris that the roller picks up from the drum.

Detection of New PCU

Before starting to use a new PCU, the machine must (a) agitate the toner/developer mix, (b) initialize the

TD sensor, and (c) initialize the PCU counter. This machine automatically detects the presence of a new

PCU and carries out these operations.

6. Detailed Section Descriptions

264

Loading...

Loading...