166

1313

Technical DocumentationTechnical Documentation

3. Corner Load Error Inspection Procedures

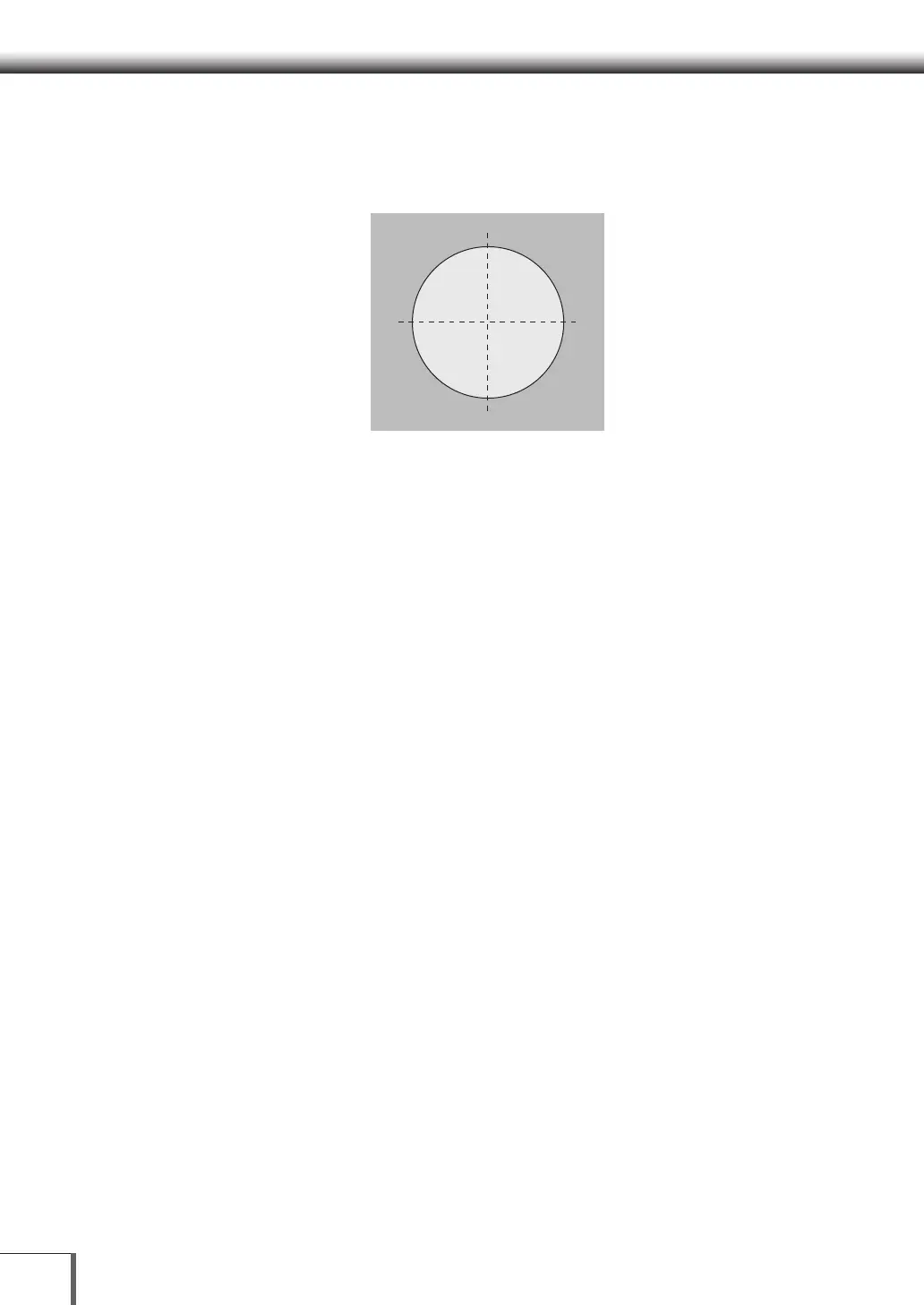

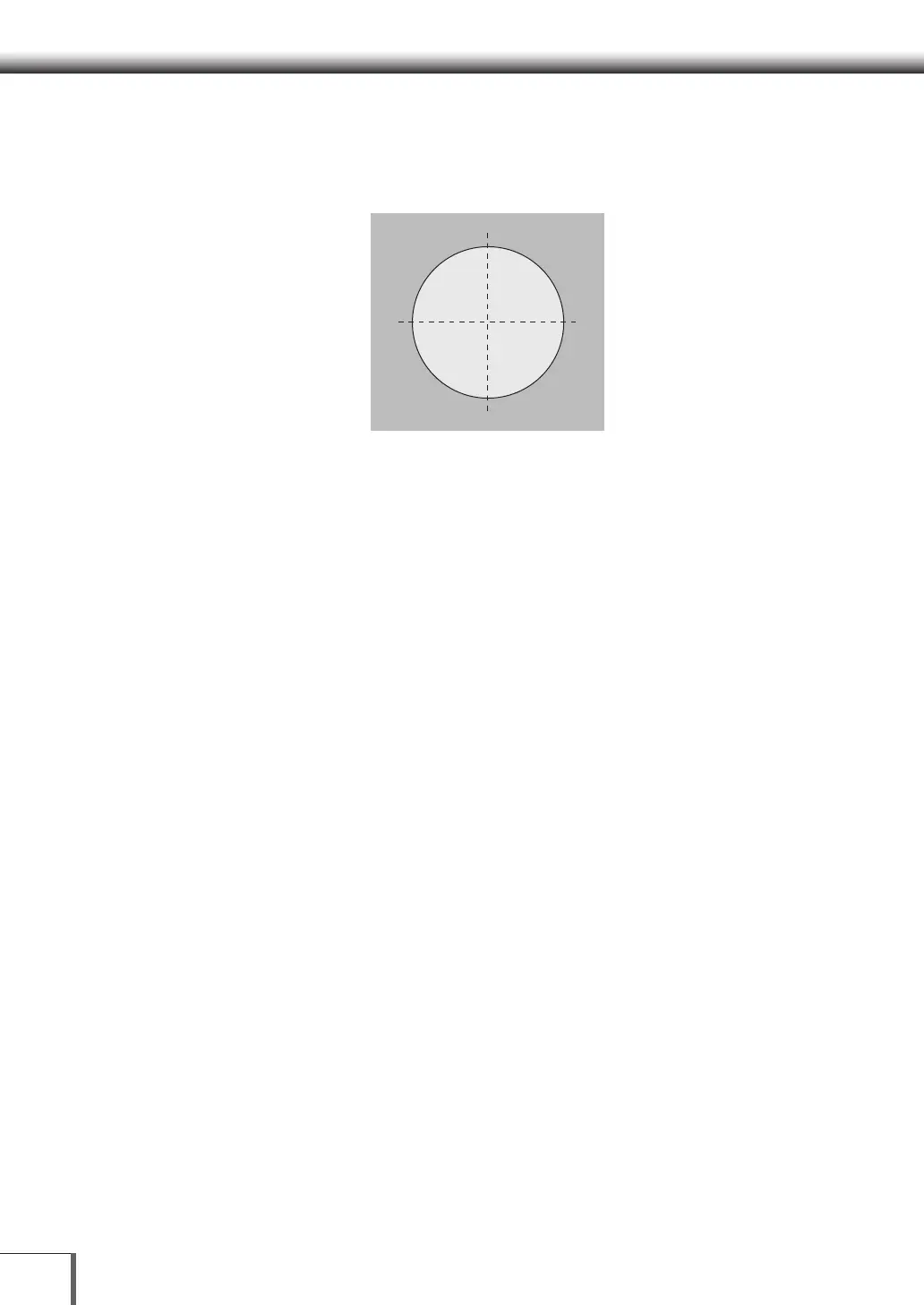

(1) Place a single weight between 1/3 to 1/2 of the capacity in sequence on the pan at the

positions shown in the illustration below, and then record the measurement values.

(Sequence) Center, Front Left, Back Left, Back Right, Front Right, Center

Back

Left

Back

Right

Front

Right

Front

Left

Center

Place the weight in the center of the pan, and then divide the plan into four and place the

weight in the center of each division.

For example, in the event of a circular pan, place the weight half way between the center and

edge of the pan.

(2) If the average value of two values with the weight placed in the center of the pan and the

difference (corner load error) when the weight is placed anywhere other than the center is

within all inspection tolerance values listed in Table 2, they will be given a pass mark. Instead

of using the average value of two values with the weight placed in the center of the pan, it is

acceptable to calculate the corner load error from the difference between the first time the

weight is placed in the center.

4. Instrumental Error Inspection Procedure

(1) Four or more measurement points, including the one close to the capacity, are set. Set these

values while referring to the following.

A) A value divided into the average capacity range, or close to it.

B) A point that replaces the inspection tolerance.

C) The load area considered important by the person requesting the inspection.

(2) Place the weights at locations that correspond with the preset measurement points in the

following sequence, and record the measurement values. Instead of the recording the zero

point measurement value, it is acceptable to only record the measurement value during the

load if the weight is placed on the pan after it has been set at zero for each display.

Zero point

First (minimum) measurement point

Second measurement point

Third measurement point

· · · ·

Maximum measurement point (close to capacity)

Zero point

(3) Subtract the average value of the first and last zero point values from the measurement

values of each measurement point. (Not necessary if the zero point was not measured.)

(4) Calculate the values obtained in the previous step and the difference (instrumental error)

between the rated weight of the weight placed on the pan, and if all values are within

inspection tolerance, they will be given a pass mark.

Loading...

Loading...