NCK start-up

10.5 Parameterize axis data

CNC Part 1 (NCK, PLC, drive)

122 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

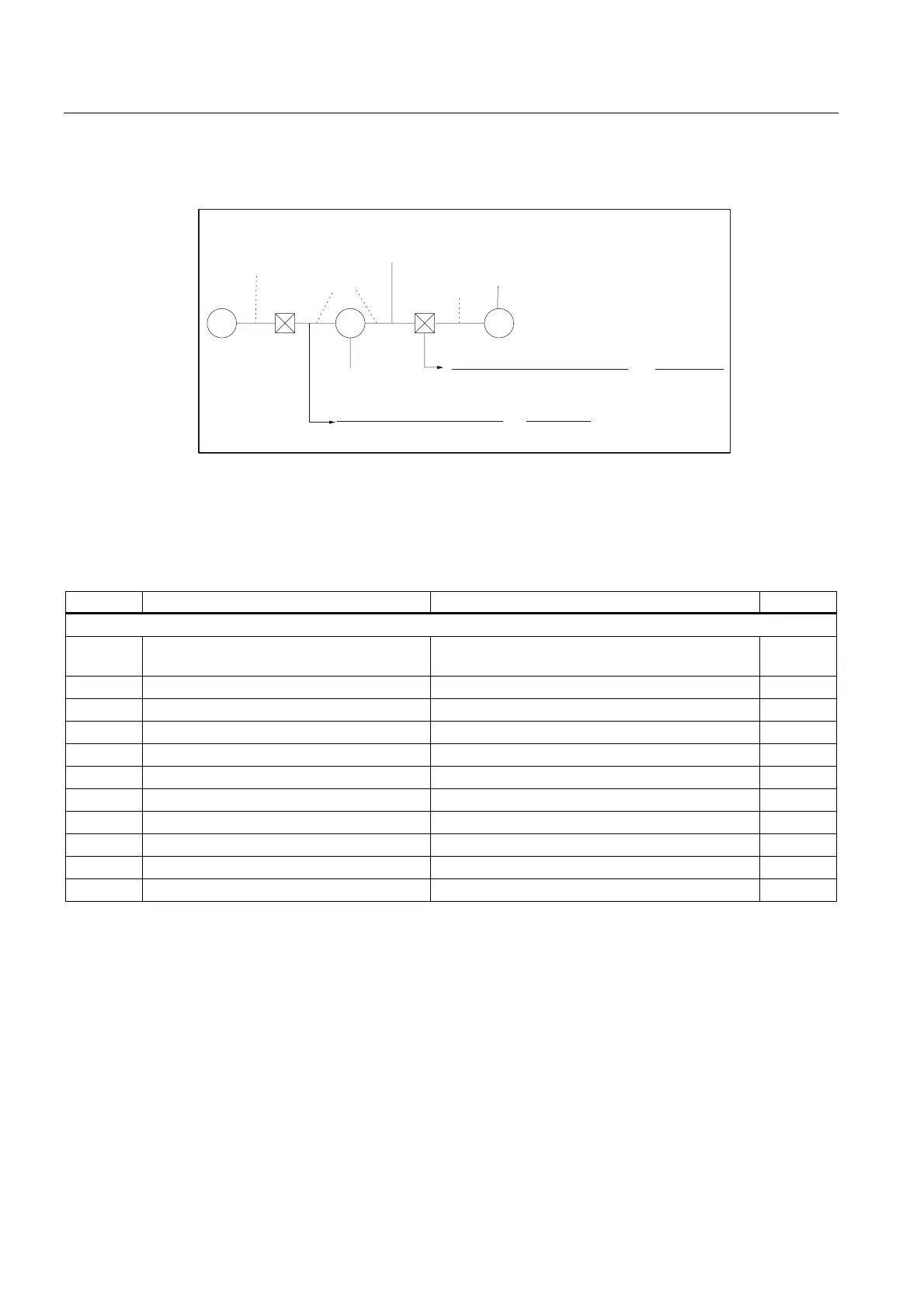

Linear axis with encoder on the machine

(1&B,6B',5(&7

(1&B5(62/

(1&B,6B/,1($5

(1&B7<3(

PRWRUUHYV

/RDGUHYV

/RDGUHYV

HQFRGHUUHYV

QPRWRU

QHQFRGHUV

QORDG

/RDG

JHDUER[

0HDV

JHDUER[

0*

(1&B,6B',5(&7

'5,9(B(1&B5$7,2B'(120

'5,9(B(1&B5$7,2B180(5$

,6B527B$;

/

'5,9(B$;B5$7,2B'(120

'5,9(B$;B5$7,2B180(5$

Figure 10-8 Linear axis with encoder on the machine

Machine data

Table 10-10 Incremental measuring systems: Machine data

Number Identifier Name / remarks Reference

Axisspecific ($MA_ ... )

30240 ENC_TYPE[n] Actual value acquisition modes

1=incremental raw signal encoder

30242 ENC_IS_INDEPENDENT[n] Encoder is independent

30300 IS_ROT_AX Rotary axis R2

31000 ENC_IS_LINEAR[n] Direct measuring system (linear scale)

31020 ENC_RESOL[n] Encoder pulses per revolution

31030 LEADSCREW_PITCH Leadscrew pitch

31040 ENC_IS_DIRECT[n] Encoder is connected directly to the machine

31050 DRIVE_AX_RATIO_DENOM[n] Denominator load gearbox

31060 DRIVE_AX_RATIO_NUMERA[n] Numerator load gearbox

31070 DRIVE_ENC_RATIO_DENOM[n] Denominator of resolver gearbox

31080 DRIVE_ENC_RATIO_NUMERA[n] Numerator of resolver gearbox

Linear measuring system

The diagram below shows the general possibilities of arranging a linear incremental

measuring system with regard to motor and load, as well as the resulting values for the

respective machine data.

Loading...

Loading...