Fundamentals

15.3 Control- and status-word bits for NCK<->drive communication

CNC Part 1 (NCK, PLC, drive)

262 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

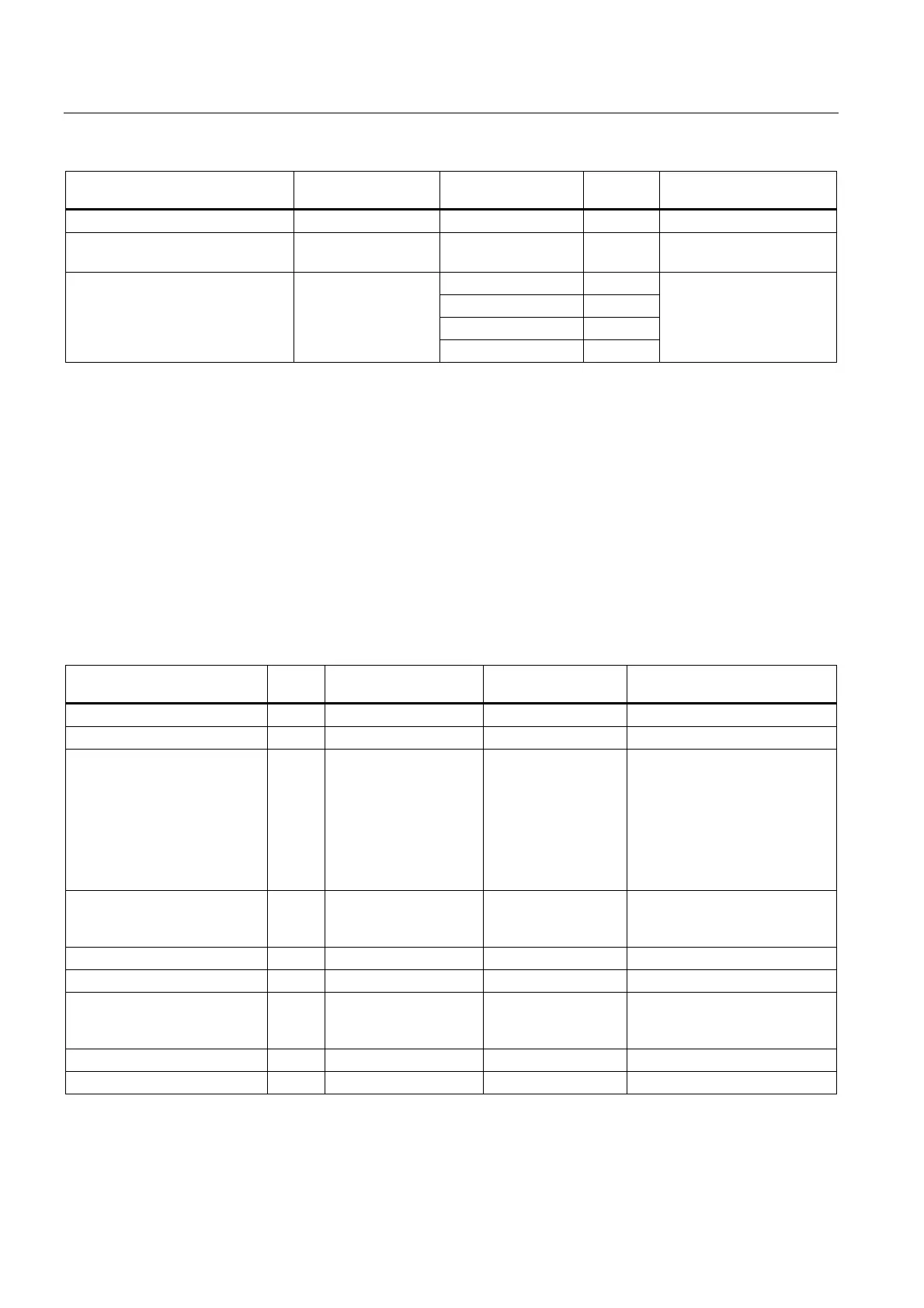

Signal provided by NCK VDI interface (PLC) Remarks Bit in

STW2

Meaning

DB(AX).DBX21.4 Bit B 10 Motor changeover, bit1

Motor selection in progress DB(AX).DBX21.5 11 Motor selection in

progress

12

13

14

Master sign-of-life No signal

15

Master sign-of-life

15.3.2 Drive to NCK

Introduction

The drive transfers the data to the NCK using message frames via a PROFIBUS interface

(internal PROFIBUS). Actual values exist for the speed control and torque and are preceded

by a status word in the message frame.

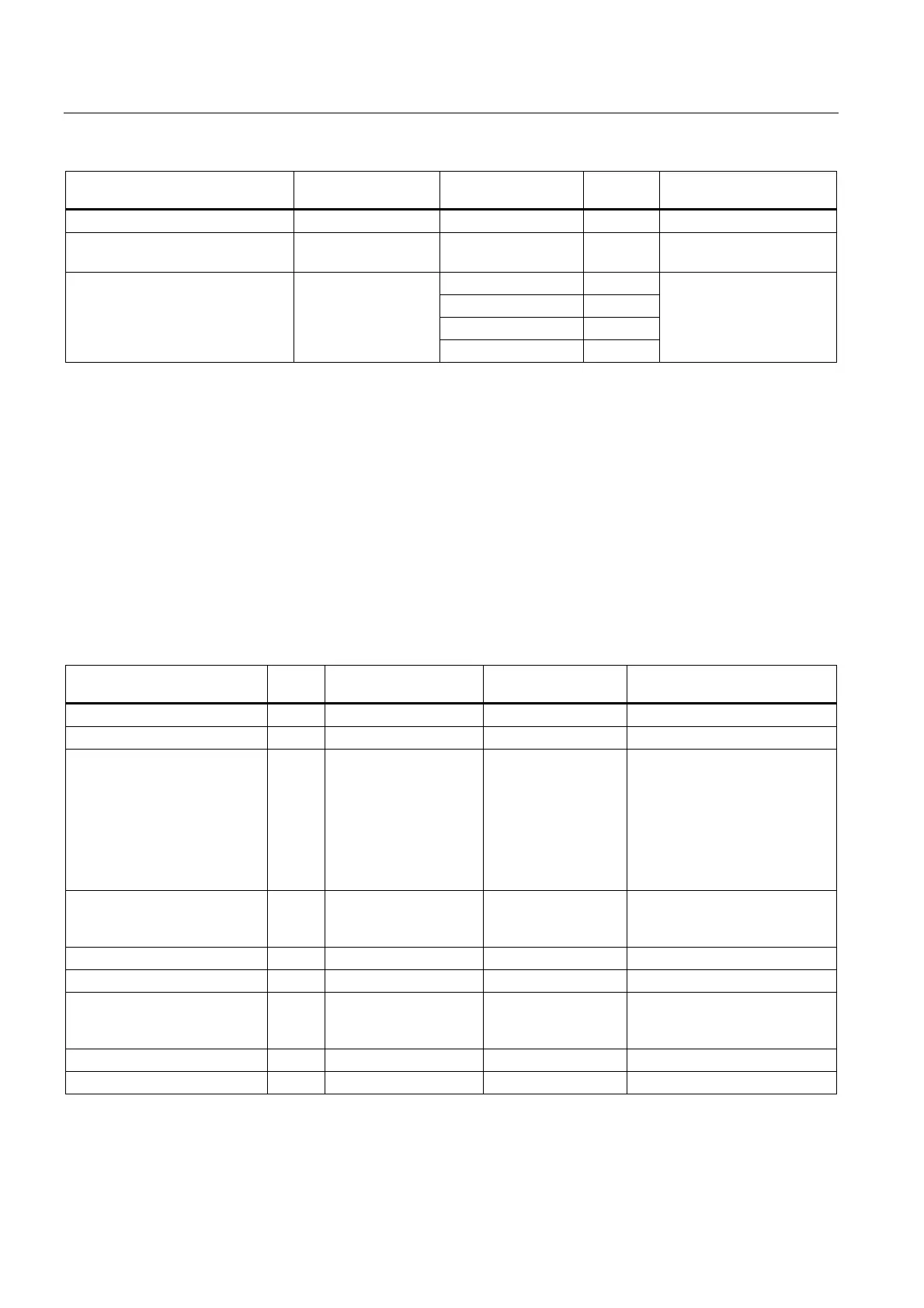

PLC interface for ZSW1

Meaning Bit in

ZSW1

Remarks VDI interface (PLC) Signal processing in the NCK

Ready to start 0 No signal

Ready-to-operate/no fault 1 No signal

Status, controller enable 2 For a combination Bit2

from ZSW1 = 0 and

simultaneously

Bit11 from the MedW =

1,

the drive is in

autonomous drive

status.

DB(AX).DBX92.4

Fault active 3 No signal Alarm 25201/25202, is used to

activate error deletion on the

NCK.

No OFF2 pending. 4 No signal Not used

No OFF3 is active 5 No signal Not used

Power-on inhibit 6 No signal Used on the NCK to generate

the "Acknowledge fault

memory" signal.

Warning present 7 No signal No evaluation

nset = nact 8 No signal No evaluation

Loading...

Loading...