NCK start-up

10.5 Parameterize axis data

CNC Part 1 (NCK, PLC, drive)

158 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

Notice

The status of the absolute encoder is only automatically reset to 1 = "encoder not

calibrated" by the NCK on gear change:

• MD34210 $MA_ENC_REFP_STATE[n] = 1

In all other cases, it is the sole responsibility of the NCK user to indicate the uncalibrated

state of the absolute value encoder by manually resetting the status to "encoder not

calibrated" and to perform calibration again.

Literature

Function Manual Basic Functions; Reference point approach: Referencing with absolute

encoders

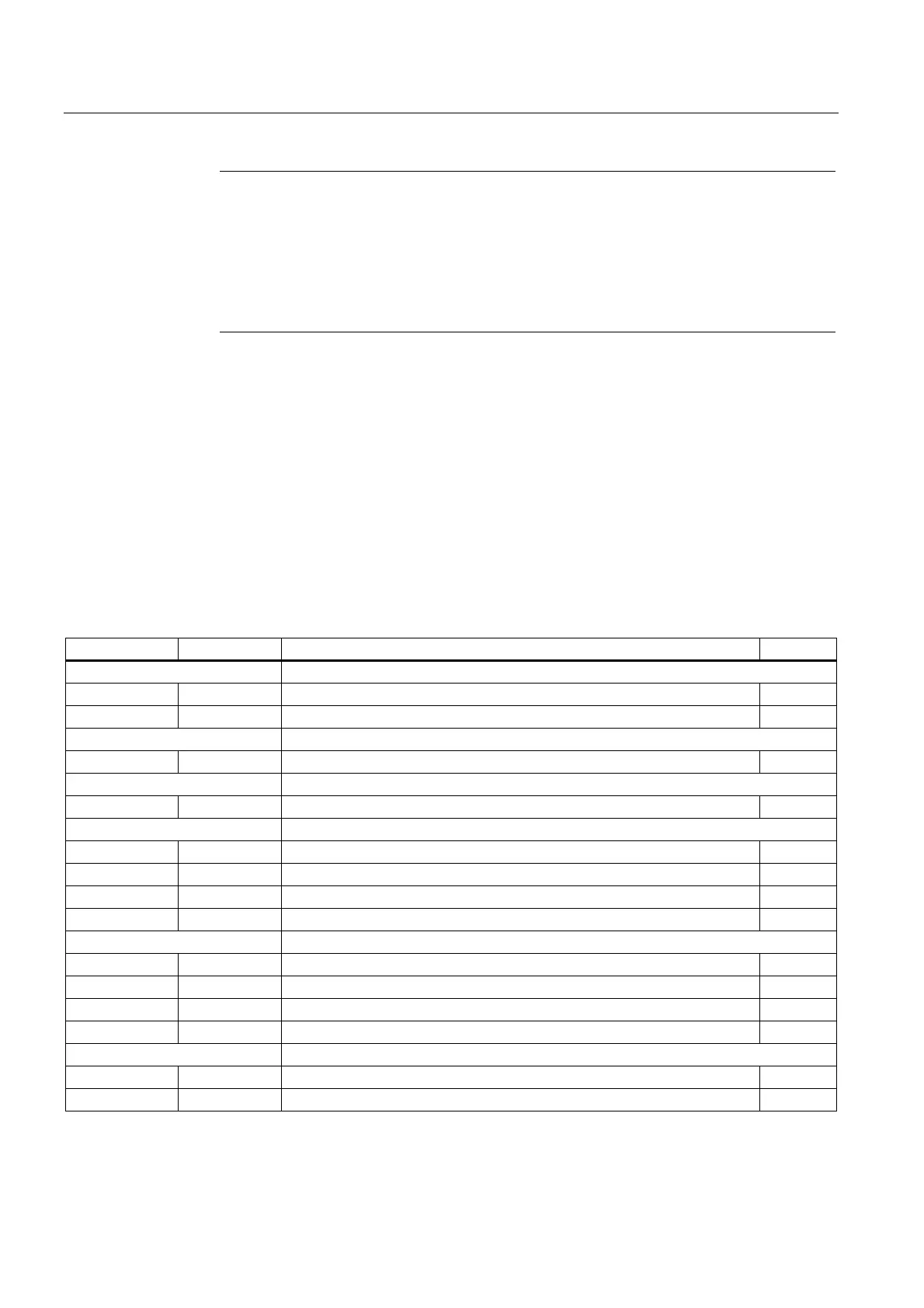

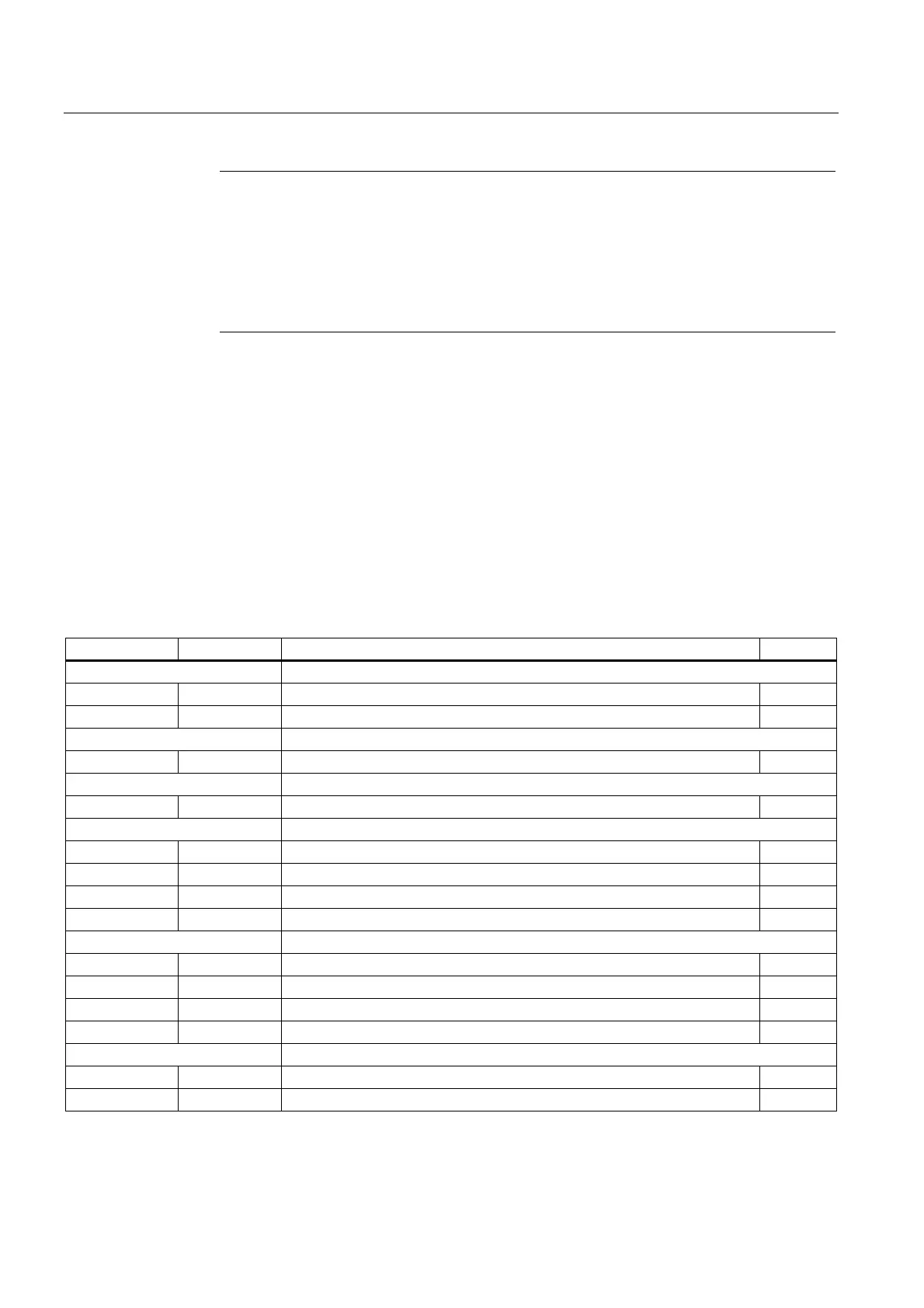

10.5.12.4 Interface signals and machine data

Interface signals

Table 10-25 Referencing: Interface signals

DB number Bit, byte Name Reference

Mode-groupspecific Signals from PLC to mode group

11, ... 0.7 Mode group reset K1

11, ... 1.2 Machine function REF K1

Mode-groupspecific Signals from mode group to PLC

11, ... 5.2 Active machine function REF K1

Channel-specific Signals from PLC to channel

21, ... 1.0 Activate referencing

Channel-specific Signals from channel to PLC

21, ... 28.7 (MMC -> PLC) REF K1

21, ... 33.0 Referencing active

21, ... 35.7 Reset K1

21, ... 36.2 All axes that must have a reference point are referenced

Axis-specific Signals from PLC to axis/spindle

31, ... 1.5/1.6 Position measuring system 1/position measuring system 2 A2

31, ... 2.4-2.7 Reference point value 1 to 4

31, ... 4.6/4.7 Traversing keys minus/plus H1

31, ... 12.7 Reference point approach delay

Axis-specific Signals from axis/spindle to PLC

31, ... 60.4/60.5 Referenced, synchronized 1/Referenced, synchronized 2

31, ... 64.6/64.7 Traverse command minus/plus H1

Loading...

Loading...