NCK start-up

10.6 Parameterization of spindle data

CNC Part 1 (NCK, PLC, drive)

168 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

Interface signals

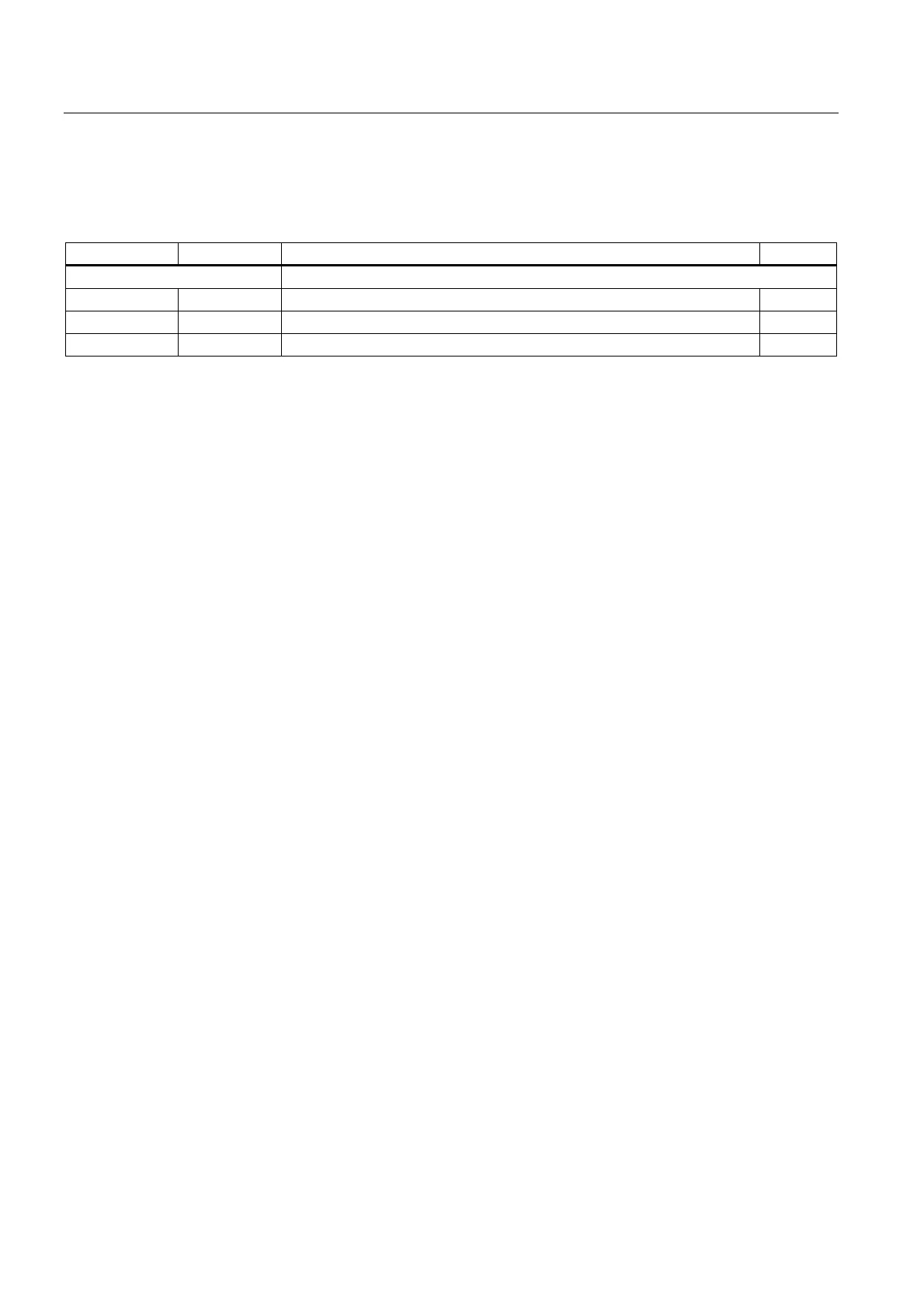

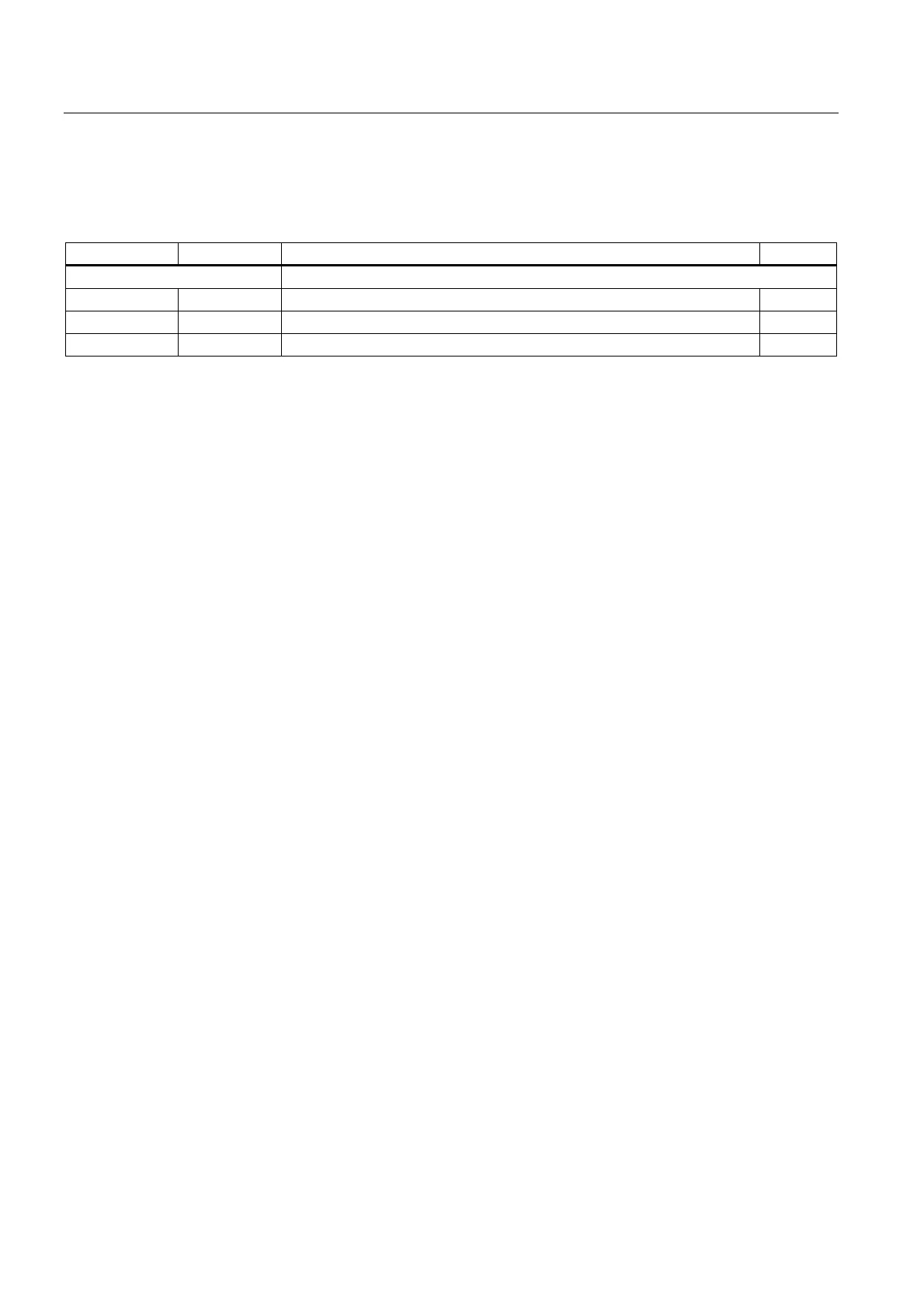

Table 10-30 Spindle positioning: Interface signals

DB number Bit, byte Name Reference

Axis-specific Signals from axis/spindle to PLC

31, ... 60.6 Position reached with exact stop "fine"

31, ... 60.7 Position reached with exact stop "coarse"

31, ... 84.5 Positioning mode

10.6.6 Synchronizing spindle

To allow the spindle to be positioned from the NCK, its position has to be adjusted using the

measuring system. This operation is called "synchronization".

As a rule, synchronizing is done to the zero mark of the connected encoder or to a reference

cam as zero mark substitute.

Machine data

• MD34100 REFP_SET_POS (reference point value)

defines the actual position of the spindle at the zero mark position.

The machine data

• MD34090 REFP_MOVE_DIST_CORR (reference-point offset)

is used to enter the zero mark offset.

Machine data

• MD34200 ENC_REFP_MODE (Referencing mode)

specifies via which signal the synchronization takes place:

1 = encoder zero mark

2 = reference cam

When is synchronization necessary?

The spindle will be synchronized:

• after the NC has powered up when the spindle is moved using a programming command

• after a request for resynchronization by the PLC

NST DB31,... DBX16.4 (resynchronize spindle 1)

NST DB31,... DBX16.5 (resynchronize spindle 2)

• after each gear stage change for an indirect measuring system

MD31040 ENC_IS_DIRECT (direct measuring system) = 0

• when the encoder limit frequency falls below the programmed value after a speed has

been programmed which is above the encoder limit frequency.

Loading...

Loading...