NCK start-up

10.6 Parameterization of spindle data

CNC Part 1 (NCK, PLC, drive)

Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

169

Notice

If the spindle encoder is not mounted directly on the spindle and there are speed-

transforming gears between the encoder and spindle (e.g. encoder mounted on motor),

then a reference cam signal connected to the drive module must be used for

synchronization. The control system then automatically resynchronizes the spindle after

each gear stage change. The user does not have to contribute anything here.

In general, backlash, gearbox elasticity and reference cam hysteresis reduce the

accuracy achievable during synchronization.

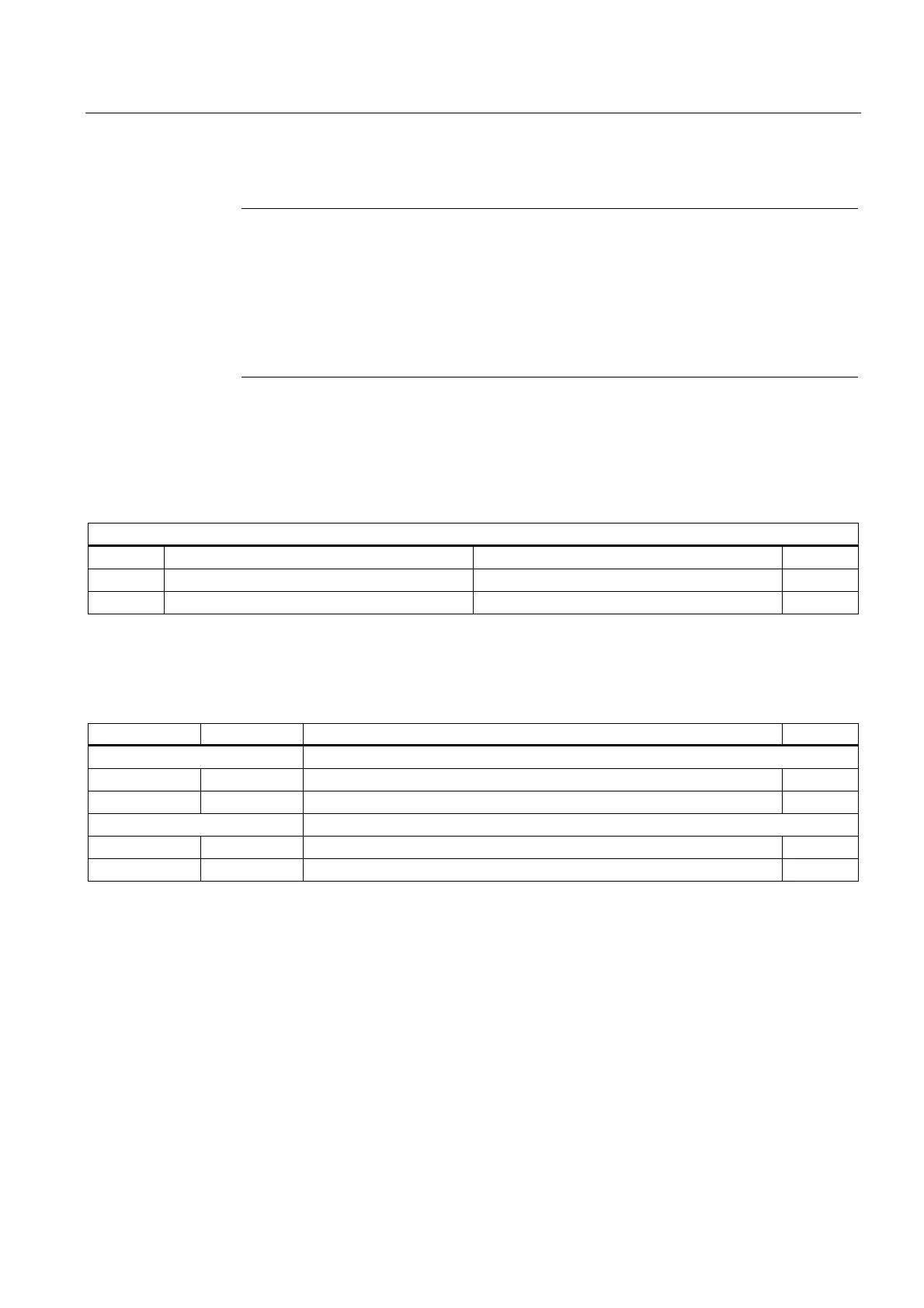

Machine data

Table 10-31 Synchronizing spindle: Machine data

Axisspecific ($MA_ ... )

34100 REFP_SET_POS Reference point value

34090 REFP_MOVE_DIST_CORR Reference point offset

34200 REFP_MODE Referencing mode

Interface signals

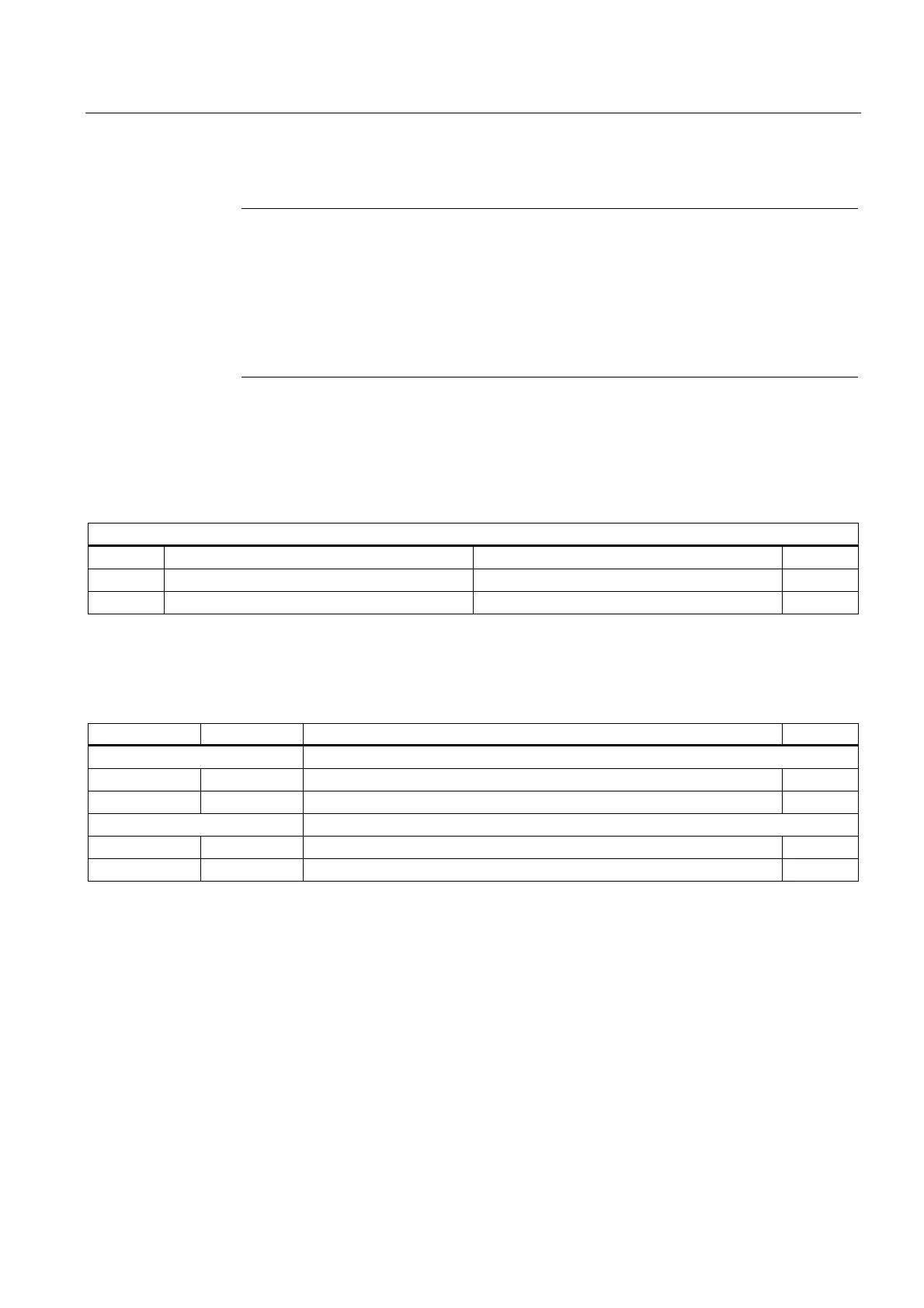

Table 10-32 Synchronizing spindle: Interface signals

DB number Bit, byte Name Reference

Axis-specific Signals from PLC to axis/spindle

31, ... 16.4 Synchronize spindle 1

31, ... 16.5 Synchronize spindle 2

Axis-specific Signals from axis/spindle to PLC

31, ... 60.4 Referenced/synchronized 1

31, ... 60.5 Referenced/synchronized 2

Loading...

Loading...