Fundamentals

15.3 Control- and status-word bits for NCK<->drive communication

CNC Part 1 (NCK, PLC, drive)

260 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

15.3 Control- and status-word bits for NCK<->drive communication

15.3.1 NCK to drive

Introduction

The NCK transfers data to the drive using message frames via a PROFIBUS interface

(internal PROFIBUS). Setpoints exist for speed control and torque and are preceded by a

control word in the message frame.

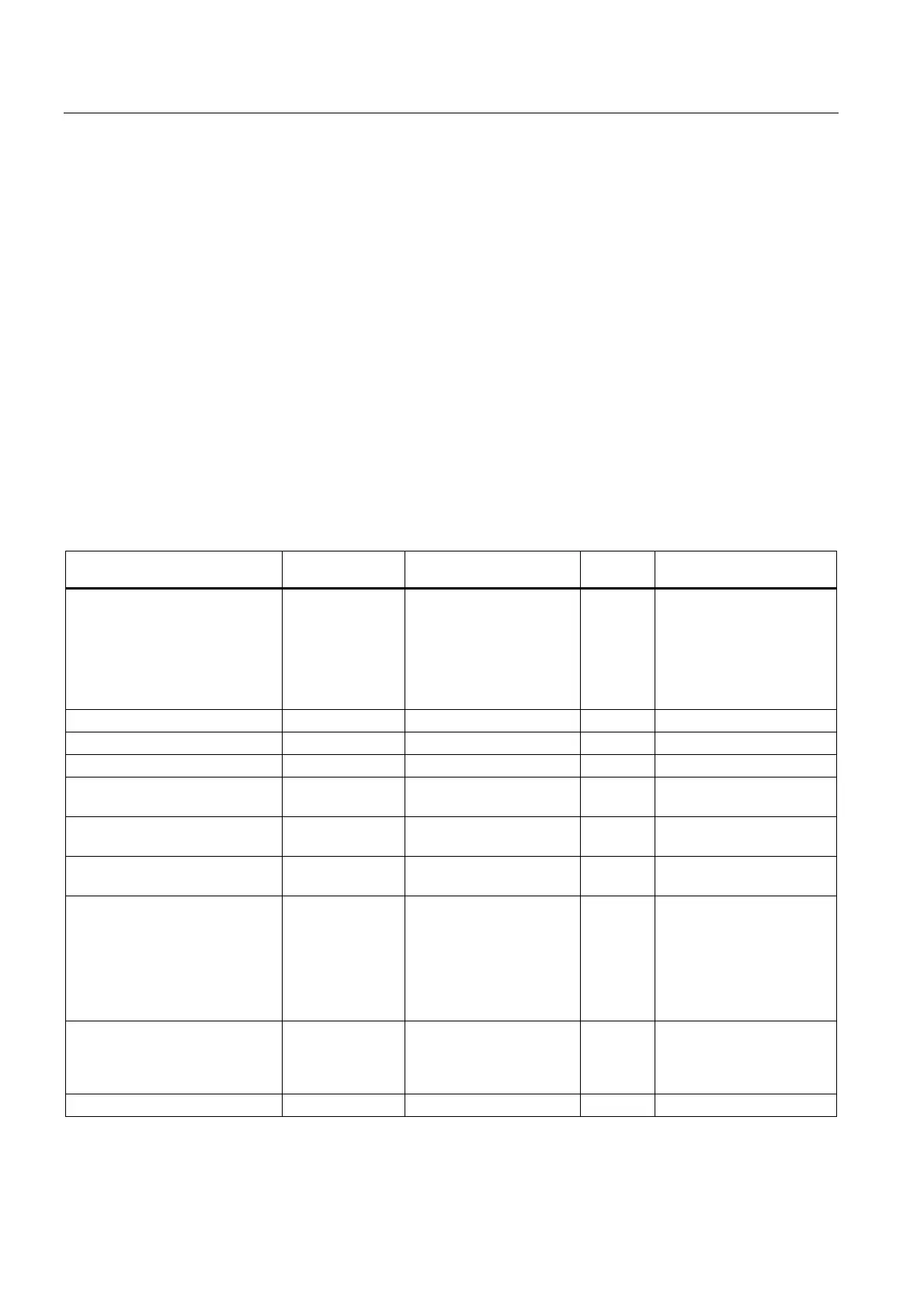

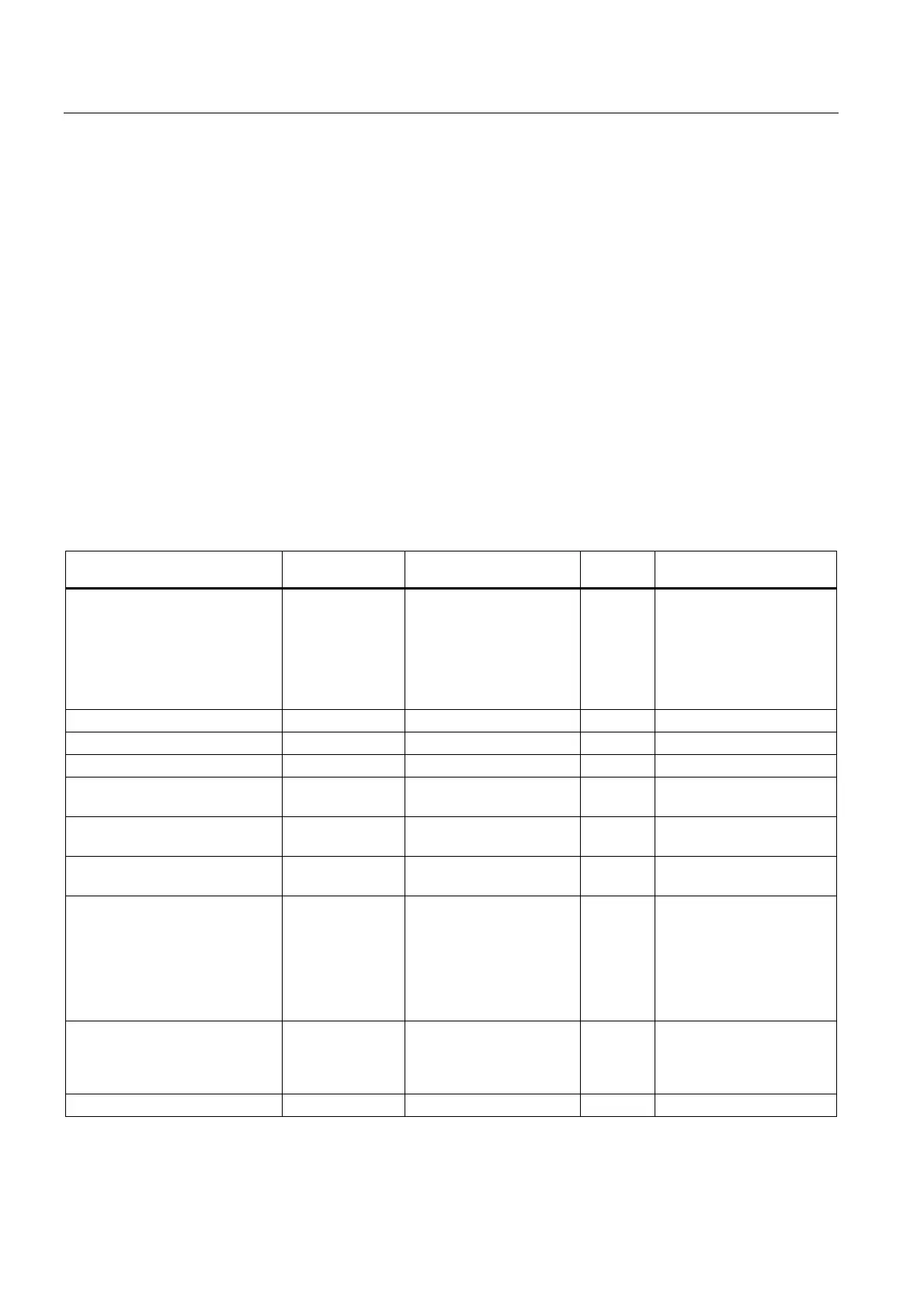

PLC interface for STW1

Signal provided by NCK VDI interface

(PLC)

Remarks Bit in

STW1

Meaning

Axis controllable from NCK:

• Servo enable

• Measuring system selected

and OK

• Pulse enable

• …

DB(AX).DBX2.1

DB(AX).DBX1.5/6

DB(AX).DBX21.7

0 OFF1

Always "1", "TRUE" No signal 1 OFF2

Always "1", "TRUE" No signal 2 OFF3

VDI signal pulse enable DB(AX).DBX21.7 3 Enable inverter

RFGIS DB(AX).DBX20.1 4 Ramp-function generator

enable

RFGIS DB(AX).DBX20.1 5 Ramp-function generator

Start

NCK controlled parallel to

STW1 bit0

6 Setpoint enable

(DriveReset) is generated by:

• "RESET signal" or CANCEL

KEY, if a simultaneous drive

fault is present (ZSW1.bit3 or

ZSW1.bit6)

No signal Signal "OFF1" is

automatically set to

FALSE internally,

simultaneously to

"DriveReset" (user must

NOT manipulate the servo

enable separately!).

7 Reset fault memory

Selection of NC function

generator (via PI service from

HMI)

No signal The user cannot influence

the function generator

selection via the VDI

interface.

8 Activate function generator

Always "0", "FALSE" No signal Signal not used 9 Reserved

Loading...

Loading...