NCK start-up

10.5 Parameterize axis data

CNC Part 1 (NCK, PLC, drive)

134 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

Checking the loop gain

If a K

V

factor is already known for a machine type in question, this can be set and checked.

For checking, reduce the acceleration of the axis in

• MD32300 MAX_AX_ACCEL (Axis acceleration)

to make sure that the drive does not reach its current limit when accelerating and

decelerating.

The K

V

factor must also be checked for high speeds of the rotary axis and spindle (e.g., for

spindle positioning, tapping).

The approach behavior at various speeds can be checked by means of a storage

oscilloscope or the HMI Advanced servo trace software. The speed setpoint is recorded for

this purpose.

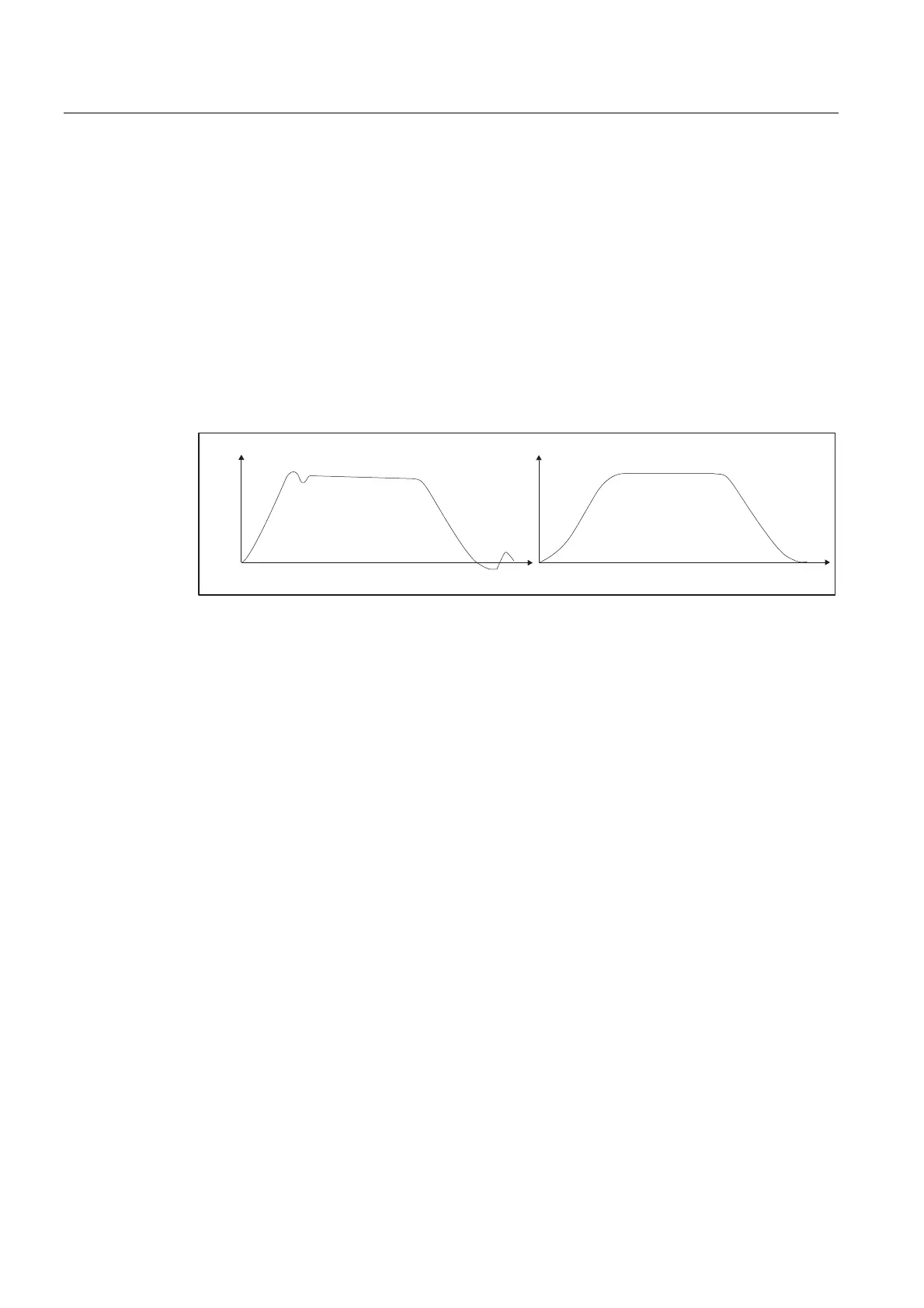

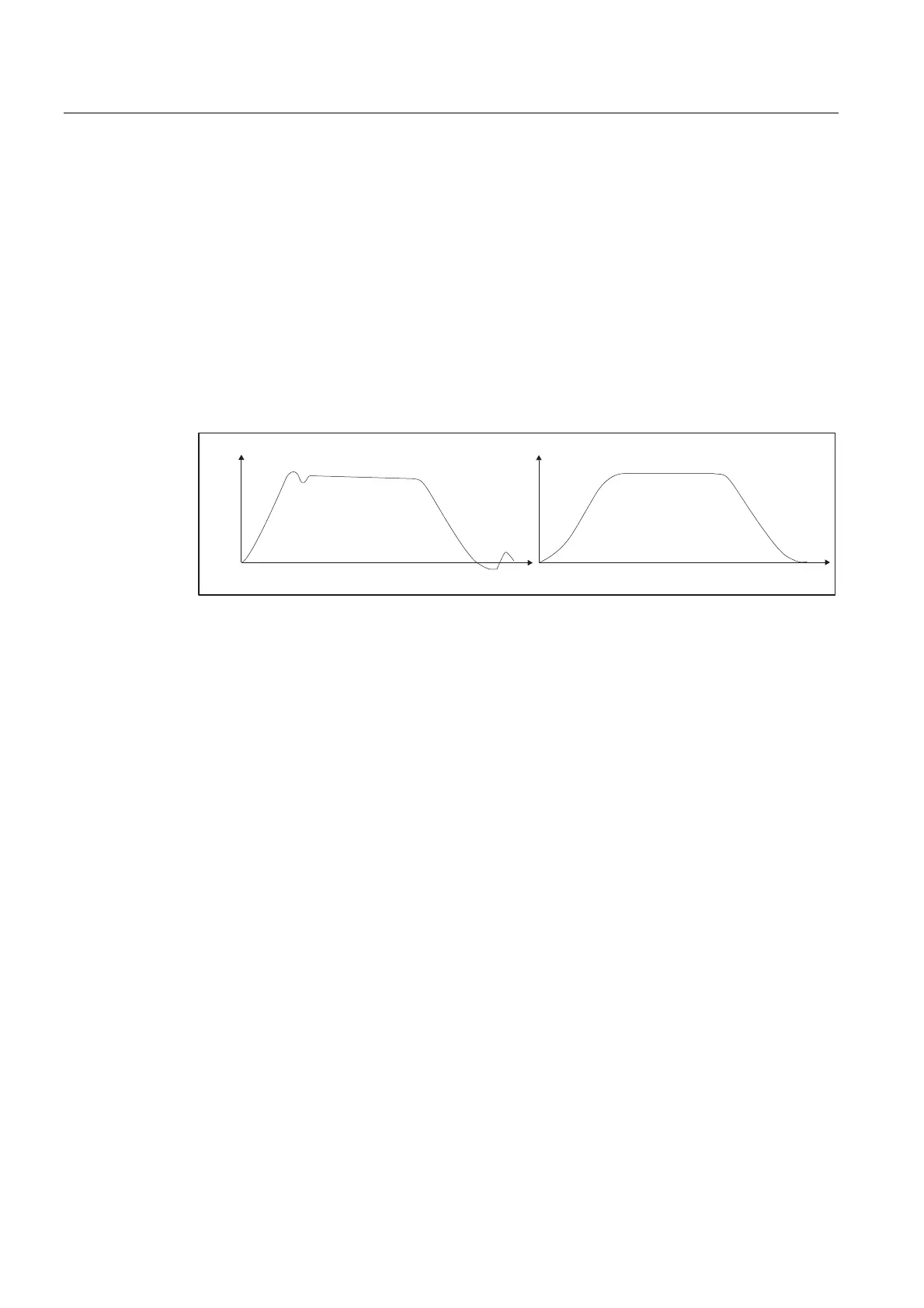

:HOO

VHOHFWHG.9IDFWRU

%DGO\

VHOHFWHG.9IDFWRU

W>PV@

>9@

QVHWS

W>PV@

>9@

QVHWS

Figure 10-13 Speed setpoint characteristic

No overshoots may occur while the drive is approaching the static states; this applies to all

speed ranges.

Overshoot in the position control loop

The reasons for an overshoot in the control loop can be:

• Acceleration too high (current limit is reached)

• Rise time too long (re-optimization necessary)

• Mechanical backlash

• Mechanical components canted

For safety reasons, set the K

V

factor for each axis to a little less than the maximum possible

value.

• MD32900 DYN_MATCH_ENABLE[n]

• MD32910 DYN_MATCH_TIME[n]

For axes interpolating with each other, the same K

V

-factor should be set. Normally it is the

K

V

-factor of the weakest interpolating axis.

Contour monitoring must be set subsequently (MD 36400 CONTROL_TOL).

Acceleration

In the following machine data machine axes are accelerated and decelerated with the values

entered.

Loading...

Loading...