Fundamentals

15.5 PLC program

CNC Part 1 (NCK, PLC, drive)

Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

275

3URFHVVDODUP

&\FOLF

SURFHVVLQJ

6WDUW"XS

*3B35$/

*32%

1&.

%$*

&KDQQHO

$[LV

6SLQGOH

70

QRW)01&

8VHU

SURJUDP

8VHU

SURJUDP

8VHU

SURJUDP

2%

2%

2%

*JURXS

'LVWULEXWRU

)%

)&

)&

0&3

++8

)&

$68%

&RQ$[HV

6SLQGOHV

)&

5HDGZULWH

YDUZULWH

3,VHUYLFHV

)%

0&3

0&3B,)0

0&3B,)7

70

70B7UDQV

70B'LU

)&

&ROGUHVWDUW

)&

)&

)DXOWDQG

2SPHVVDJH

YLRODWLRQV

)&

6WDUGHOWD

)&

++8

'LVSOD\

FRQWURO

)&

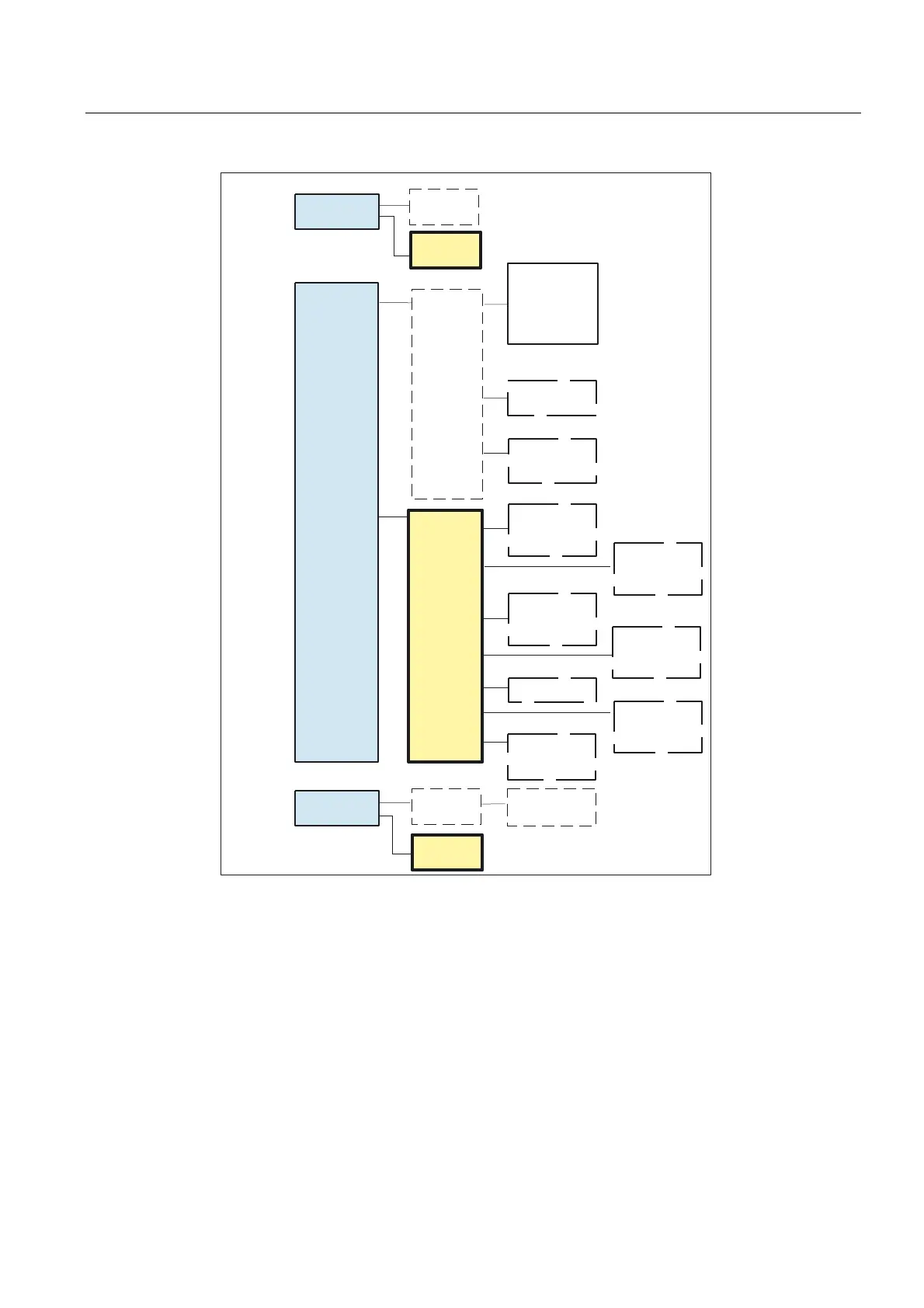

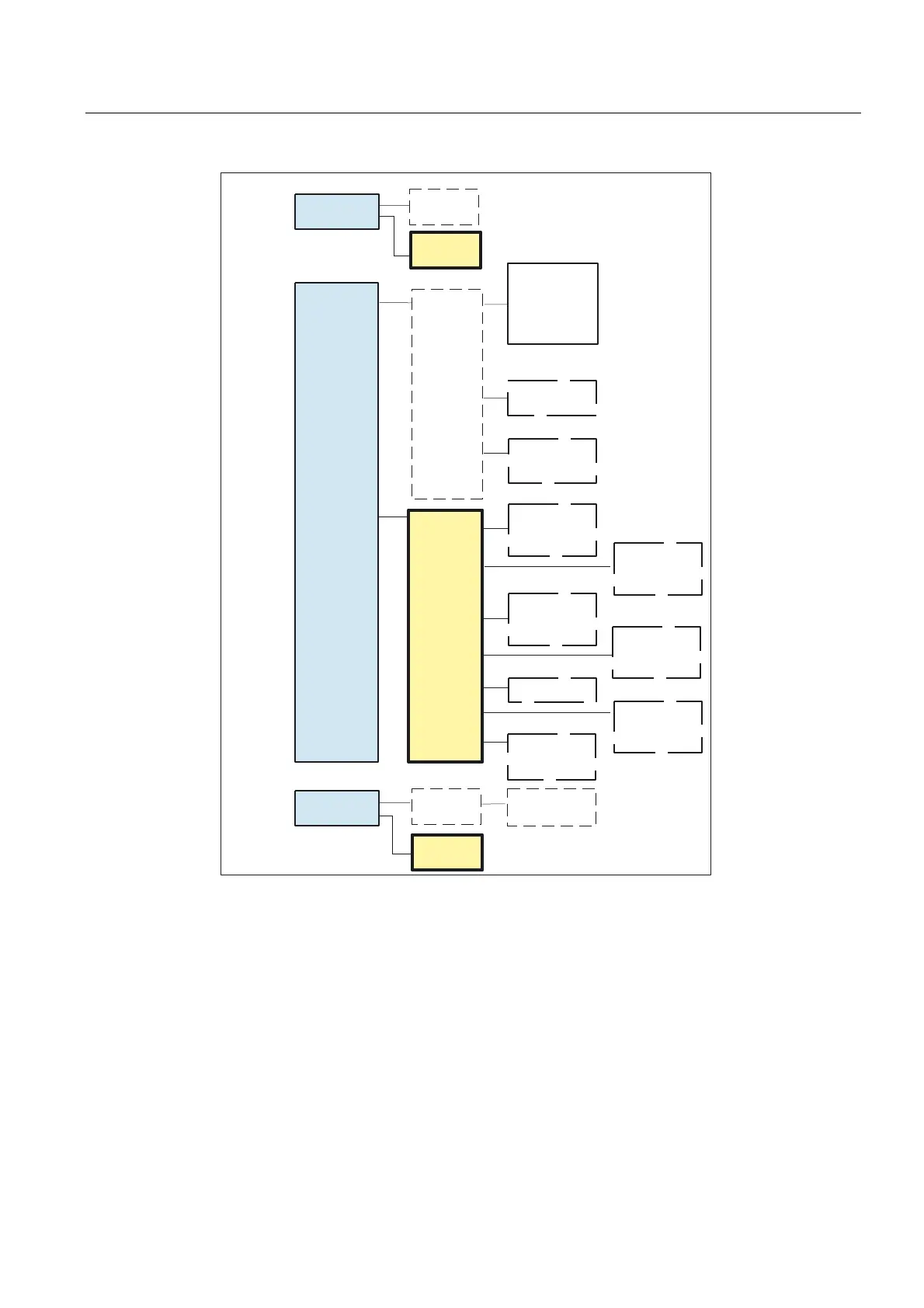

Figure 15-6 PLC program structure

PLC status

The PLC always starts up in RESTART mode, i.e. the PLC operating system runs OB100

after initialization and starts cyclic operation at the beginning of OB1. There is no re-entry at

the point of interruption (e.g. on power failure).

Start-up behavior of the PLC

There are both remanent and non-remanent areas for the markers, times and counter. The

areas are continuous and are divided by a parameterizable limit, where the area with the

Loading...

Loading...