5

Parameters operating area 01/2008

5.6 Zero/work offset

5

© Siemens AG 2008 All rights reserved.

5-230 SINUMERIK 840Di sl/840D sl/840D Operating Manual HMI-Advanced (BAD) - 01/2008 Edition

5.6 Zero/work offset

5.6.1 Function

Machine/

tool zero

The actual values are referred to the machine zero after a reference

point approach. The machining program of the workpiece refers to the

workpiece zero.

Machine zero and workpiece zero need not be identical. Depending

on the type of workpiece and the way it is clamped, the distance

between the machine zero and workpiece zero can vary. In part

program processing this is compensated for by the work offset.

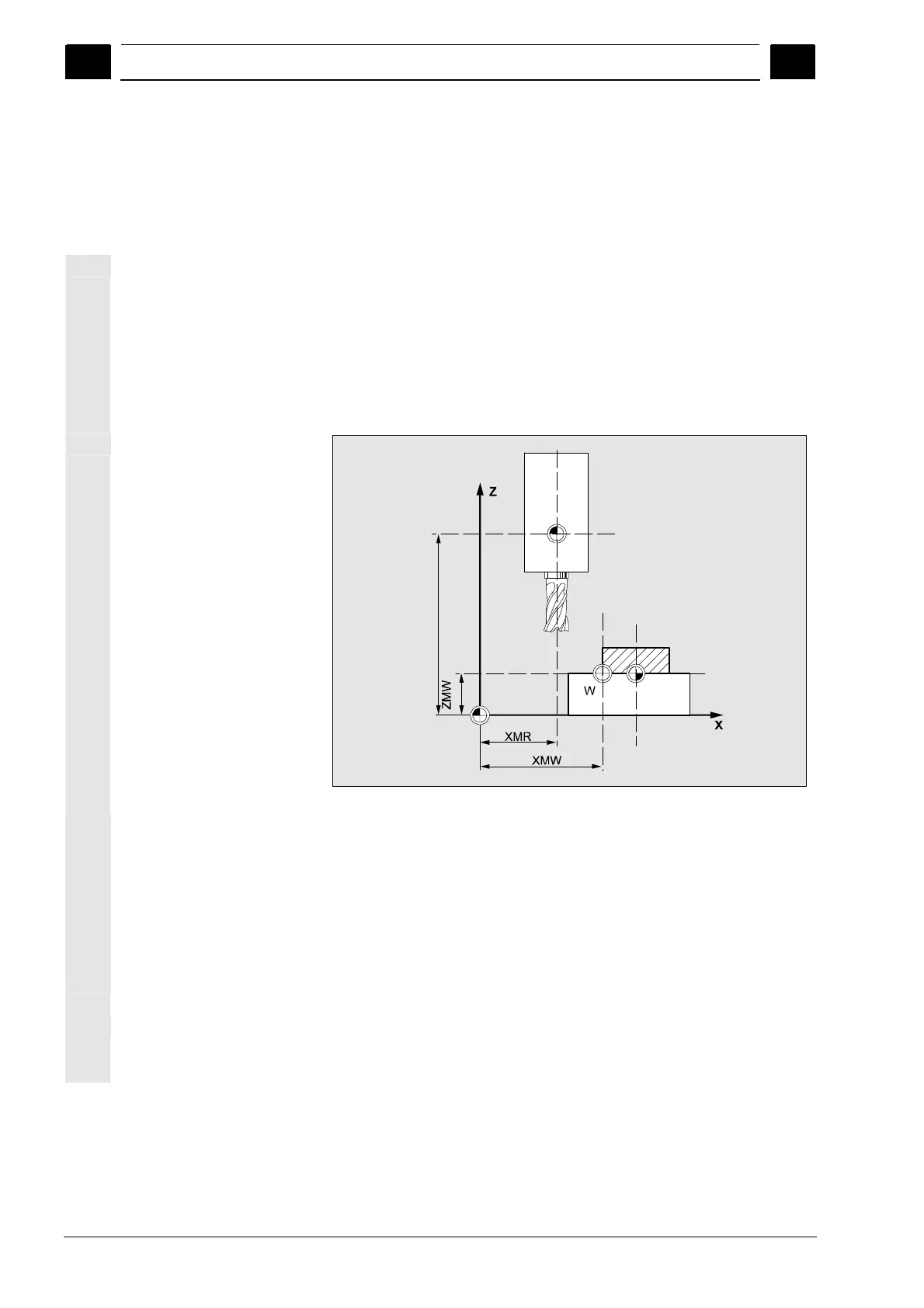

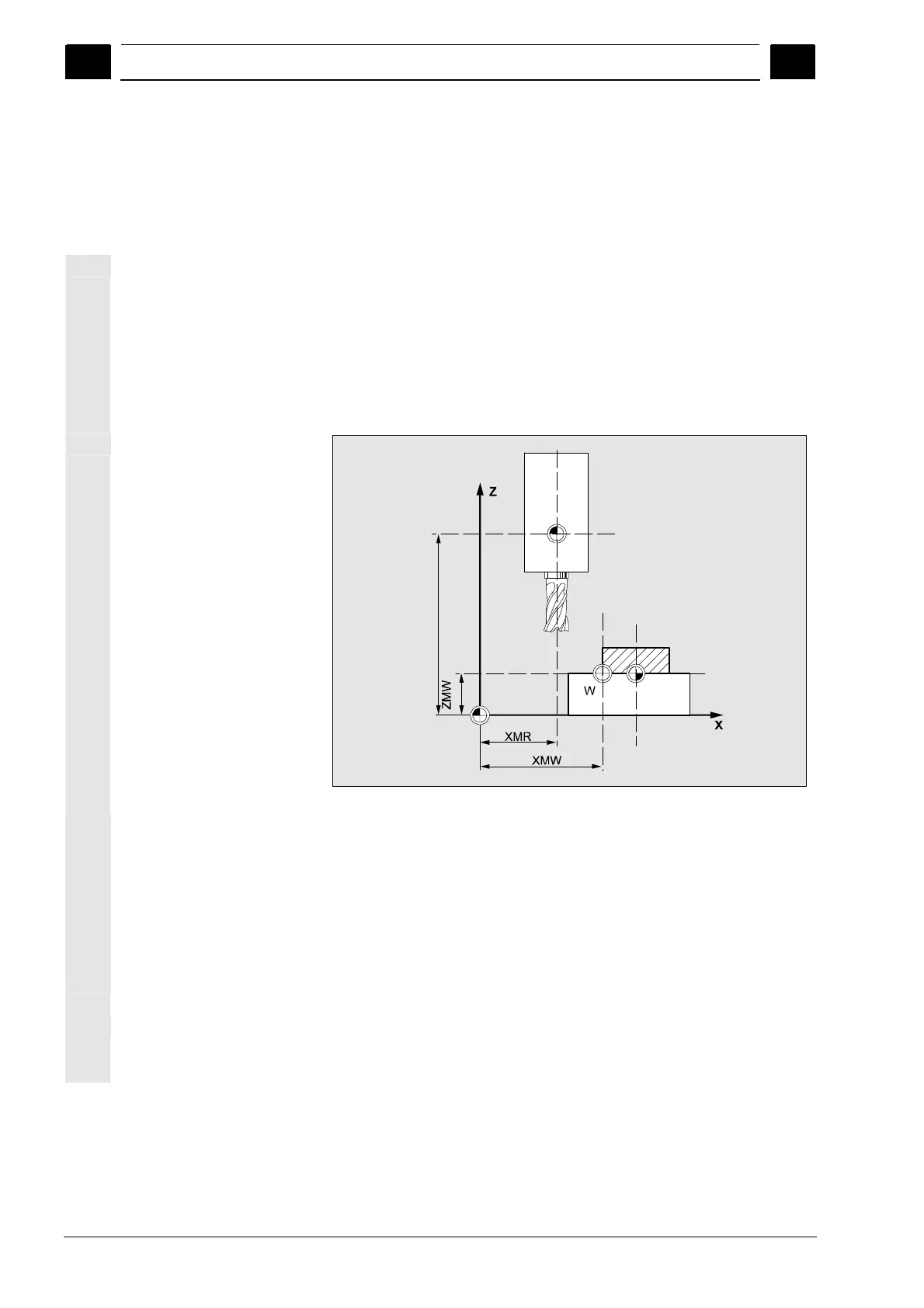

Work offset on a milling

machine

P

R=F

M

ZMR

WR

P

Tool setting point

W

Workpiece zero

F

Slide reference point

XMR, ZMR

Reference point coordinates

XMW, ZMW

Zero/work offset

M

Machine zero

R

Machine reference point

WR

Workpiece reference point

Effective WO

The work offset effective in an axis

$P_ACTFRAME=..

results from the sum of the following zero point

offsets:

Loading...

Loading...