© Stäubli 2009 – D28070504A CS8C146 / 248

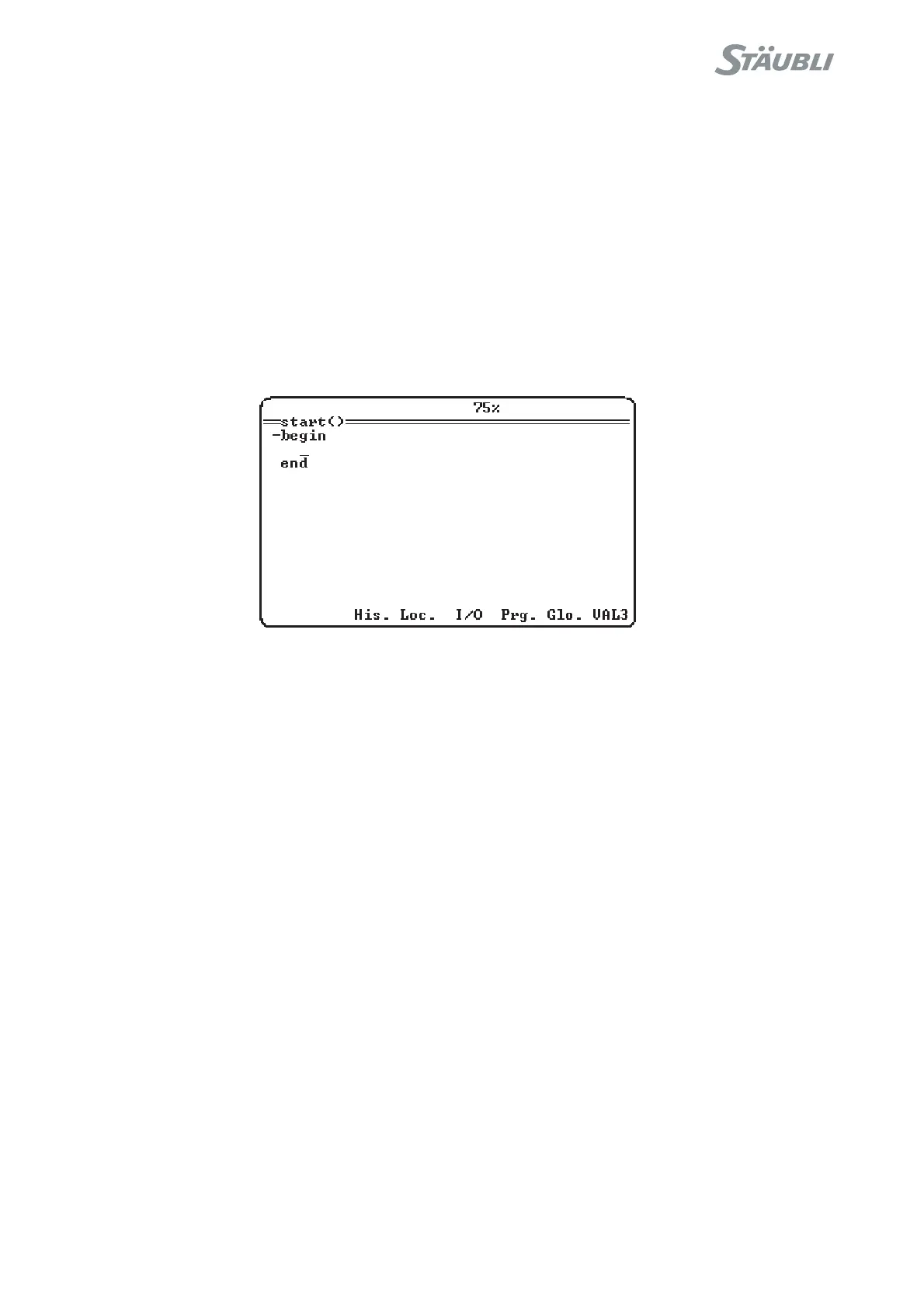

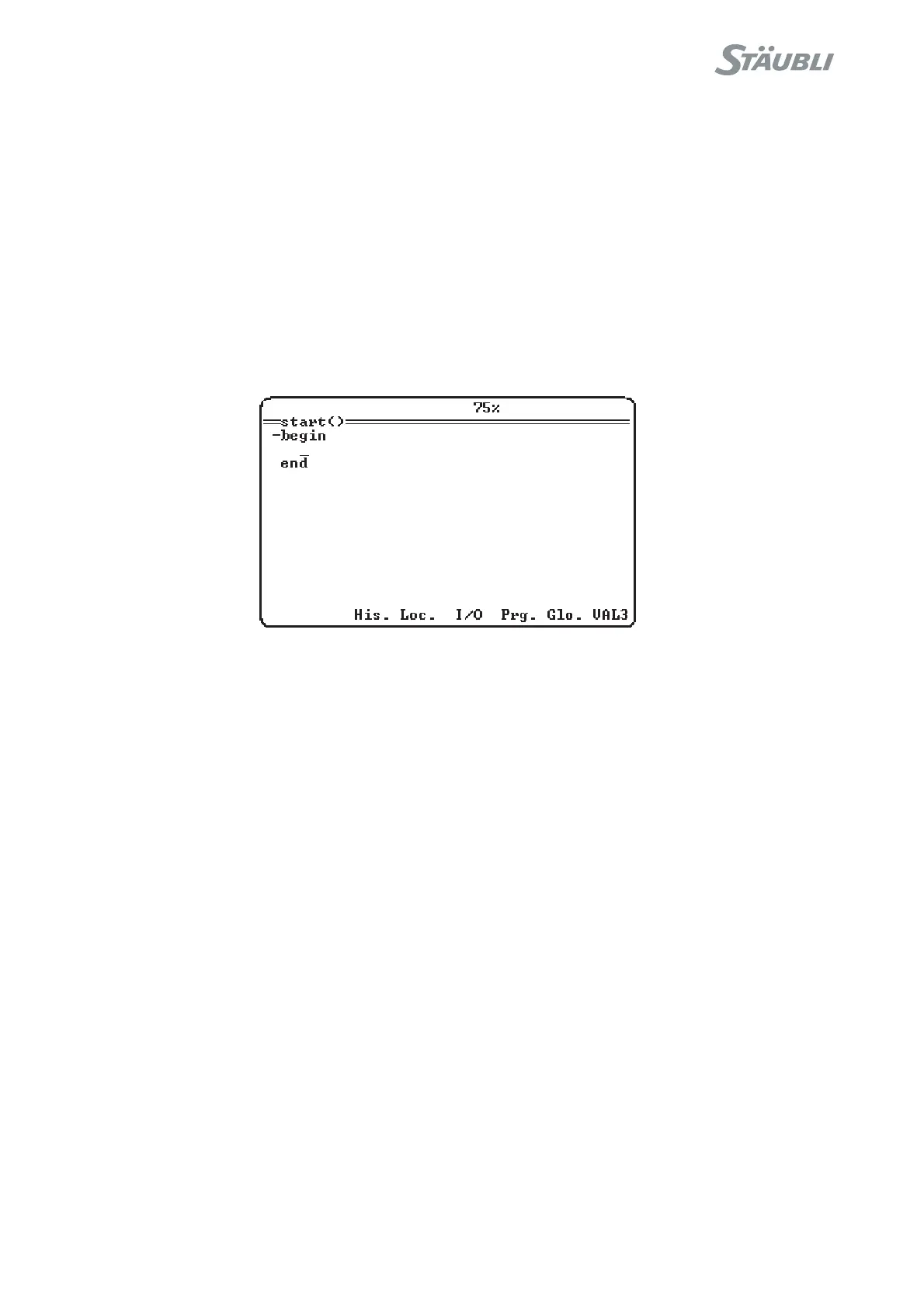

When adding or modifying an instruction, a list of menus makes it easier to enter. (see figure 6.17)

• His. enables you to select an instruction in the list of the last 20 instructions entered.

• Loc. enables you to search for or create a local variable or a parameter.

• I/O enables you to select an Input/Output.

• Prg. enables you to select or create a new program.

• Glo. enables you to select or create a global variable.

• VAL3 enables you to select an instruction in the list of VAL3 instructions.

It is possible to insert a breaking point in an instruction (see paragraph 6.10.3).

To exit, press the Esc key.

Figure 6.17

Loading...

Loading...