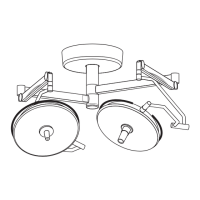

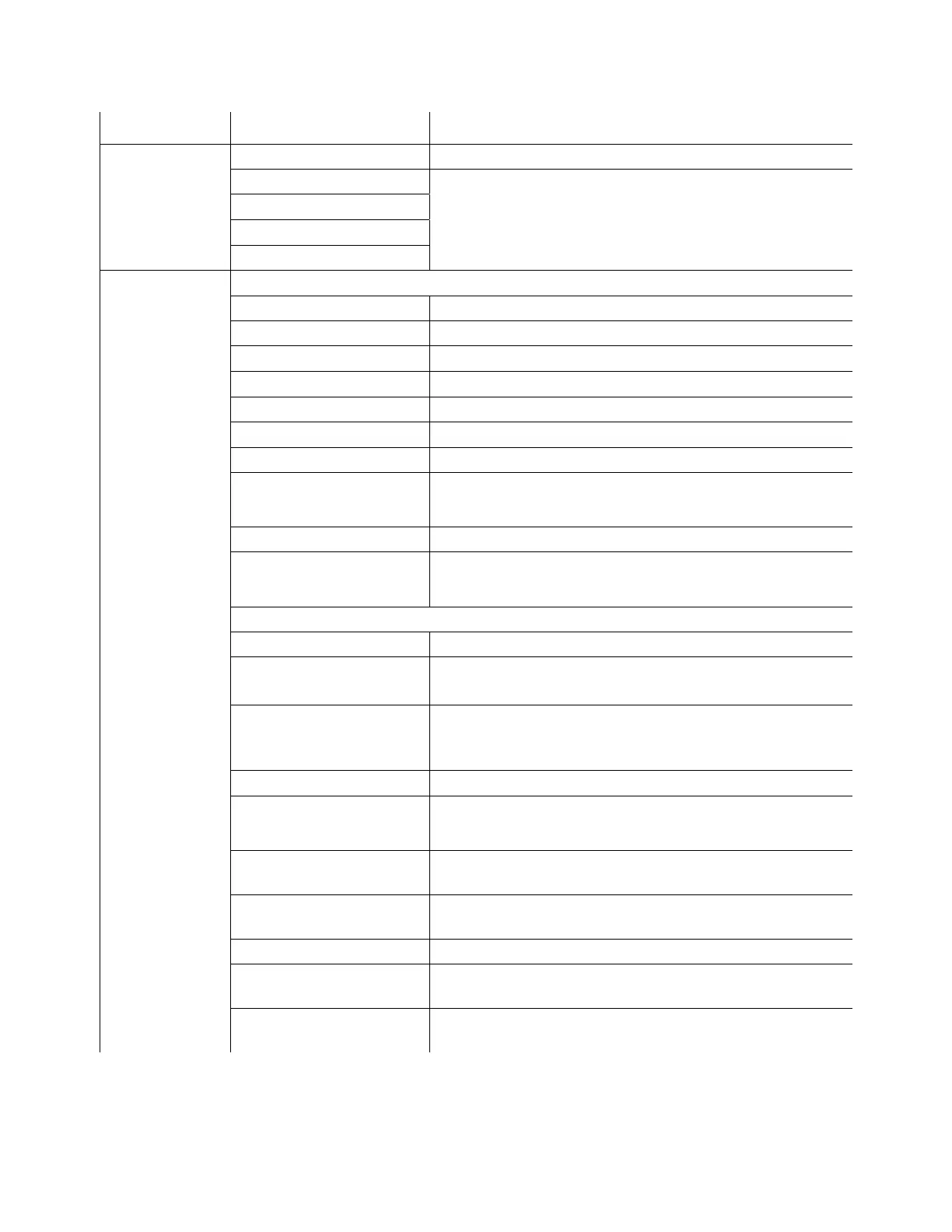

Menu Option Displays Detail

Docking

Cycles

Quick Drain

Press OK to perform the selected cycle. (If connected to a

docking station)

Wash

Extended Wash

Shipping

Level Sensor

Level Sensor Menu

Level Data

Float Hexadecimal value for the float sensor position

Ref Hexadecimal value for the reference magnet position

Diff Difference in the reference and float magnet positions

Volume Displays the fluid volume for each canister (in milliliters)**

Calibrate Float

4L Canister Press OK to enter the calibration screen

1000 ml

Use up and down arrows to adjust the amount of fluid used

for calibration. Acceptable range is 500ml - 1500ml.

(1000ml is ideal)

20L Canister Press OK to enter the calibration screen

1000 ml

Use up and down arrows to adjust the amount of fluid used

for calibration. Acceptable range is 500ml - 1500ml.

(1000ml is ideal)

Vacuum

Vacuum Menu

Regulator

Enc

Indicates the total angle of rotation for the regulator disk.

(This value is typically 110˚ – 113˚ )

Avg Mcur

Displays the average current draw of each regulator.

(This value is updated each time the rover initializes)

Current draw should not exceed 1500mA.

Pos Displays the real-time position of the regulator disk.

PS Volt

Displays the real-time voltage of the power supply.

Should be ≈ 18vdc when docked, when plugged in ≈ 25vdc

- 40vdc.

PS Cur

Displays the real-time current of the power supply.

This should typically be less than 100mA.

Mcur

Displays the real-time current draw of the regulator.

(This is different from the average motor current.)

Sensors

Pri

Displays the primary vacuum sensor readings for the

small canister (left side) and large canister (right side).

Sec

Displays the secondary vacuum sensor readings for the

small canister (left side) and large canister (right side).

* The shipping cycle uses antifreeze instead of detergent to prepare the equipment for shipping in areas with sub freezing

temperature.

** The level sensor “Volume” display reading is four digits. The unit of measure is mL. Therefore, a reading of 2380 equals 2.38

liters.

5-19

Loading...

Loading...