Overview

Maintenance and Cleaning Overview of PID

EVM Series User Manual

Maintenance and Cleaning Overview of PID

Periodic maintenance is encouraged to ensure accurate VOC measurements. If you are in an

environment with high concentrations of VOCs with aerosols and high particulates, you will want to

check the calibration frequently and clean the components. When the PID loses sensitivity, you will want

to change the electrode pellet.

NOTE: Due to the increased sensitivity of the PID ppb sensor, it is recommended to replace this

pellet more often. (See Appendix A Accessories and adapters for details.)

The following are three recommended maintenance/cleaning benchmarks, recommended by

Ion Science.

1. After performing a zero calibration, the baseline climbs. (You should replace the electrode pellet).

2. Under highly humid conditions, replacement of the electrode is needed.

3. If the baseline is unstable or shifts when you move the PID, then cleaning is needed.

Cleaning PID Sensor

Cleaning of the PID sensor requires removing the plastic, intelligent sensor casing, removing the

electrode pellet, and removing the lamp. Once removed, the lamp is cleaned off with the cleaning kit

(available as an optional accessory). The flowing procedures explain how to clean the PID sensor

components.

Removing and Cleaning the sensor

1. Remove the PID sensor (follow steps outlined in, “Removing and Installing PID Sensor.)

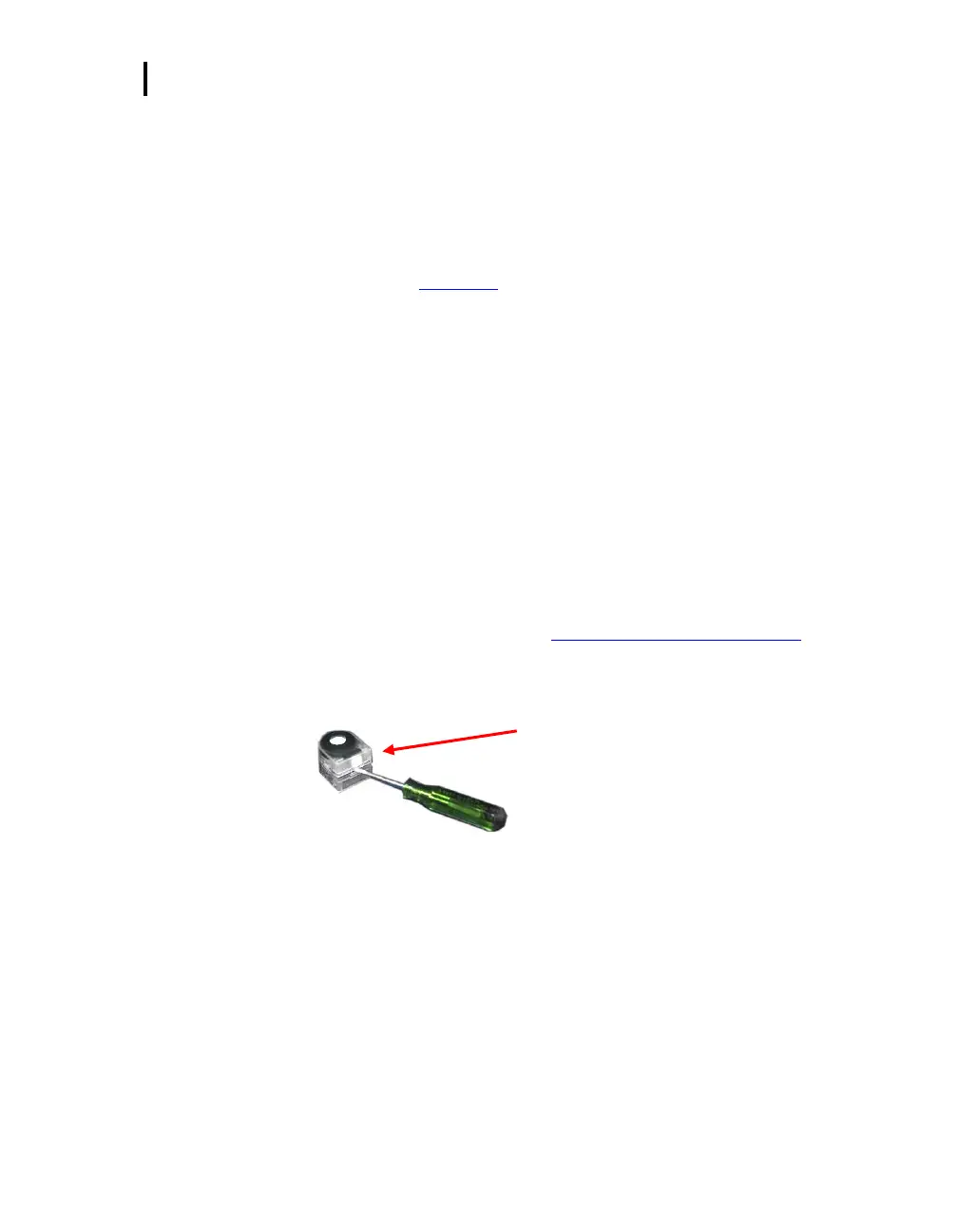

2. Using a flat-head screwdriver, gently pry open the plastic, intelligent sensor casing where the small

rectangle crevice is on the backside of the housing. Using some force, lift the top off (the bottom

section is glued in.)

Figure 7-2: Removing intelligent-sensor casing with PID

Remove intelligent

sensor casing

Loading...

Loading...