Placement and Calibration of Sensors

Calibrating Photo-Ionization Detector (PID) Sensor

EVM Series User Manual

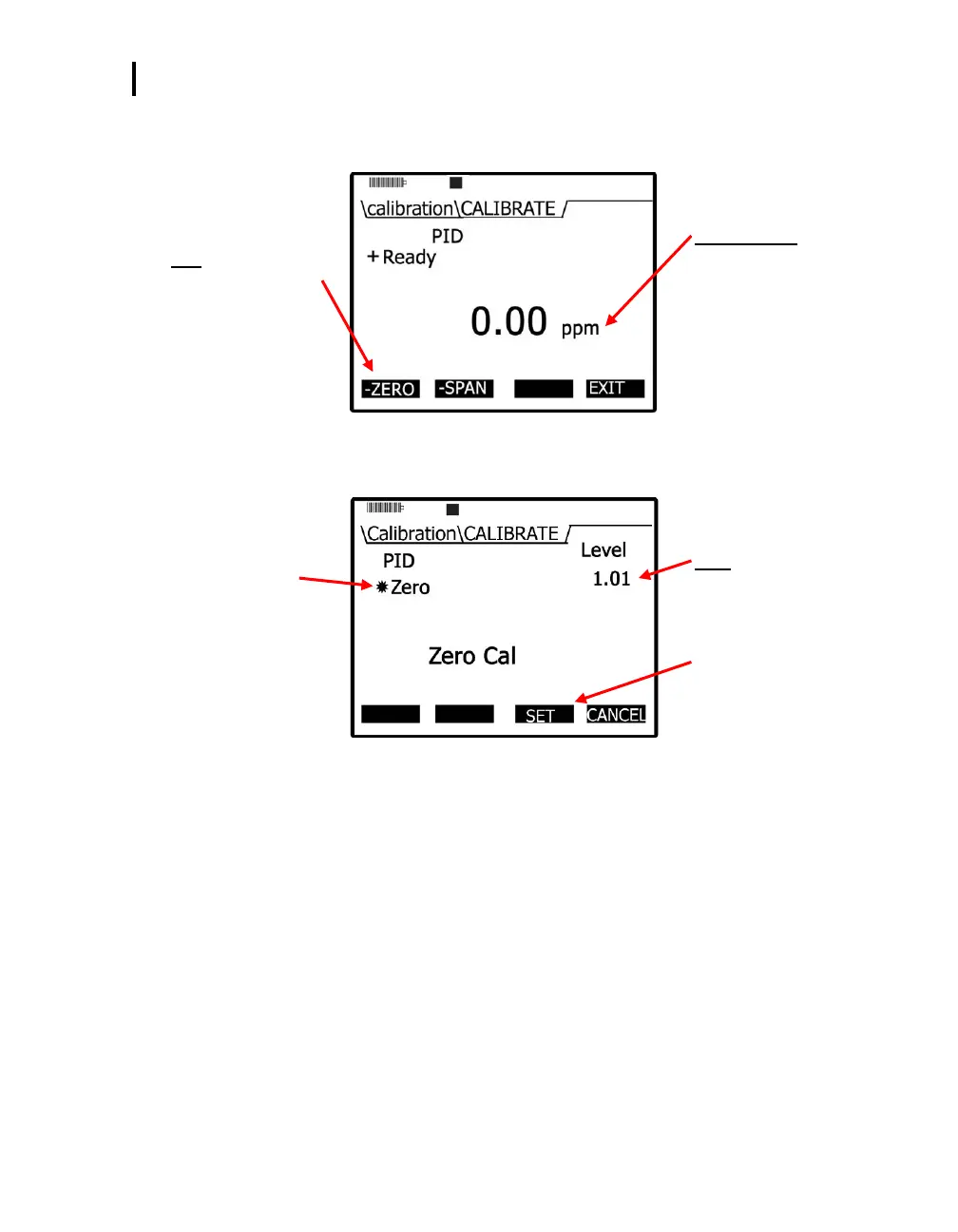

4. Press the Cal soft key and the Calibrate PID/Ready screen will appear. Press Zero soft key.

NOTE: Allow at least 60 seconds to stabilize.

Zero

With PID ppb sensor, if

“Zero” is not displayed,

this indicates the PID

setup PPB sensor

should be set. See PID

ppb zero cal. section

above.

Units: ppm/ppb

The EVM will automatically

display the attached sensor

which is either PID ppm or

PID ppb for VOC testing.

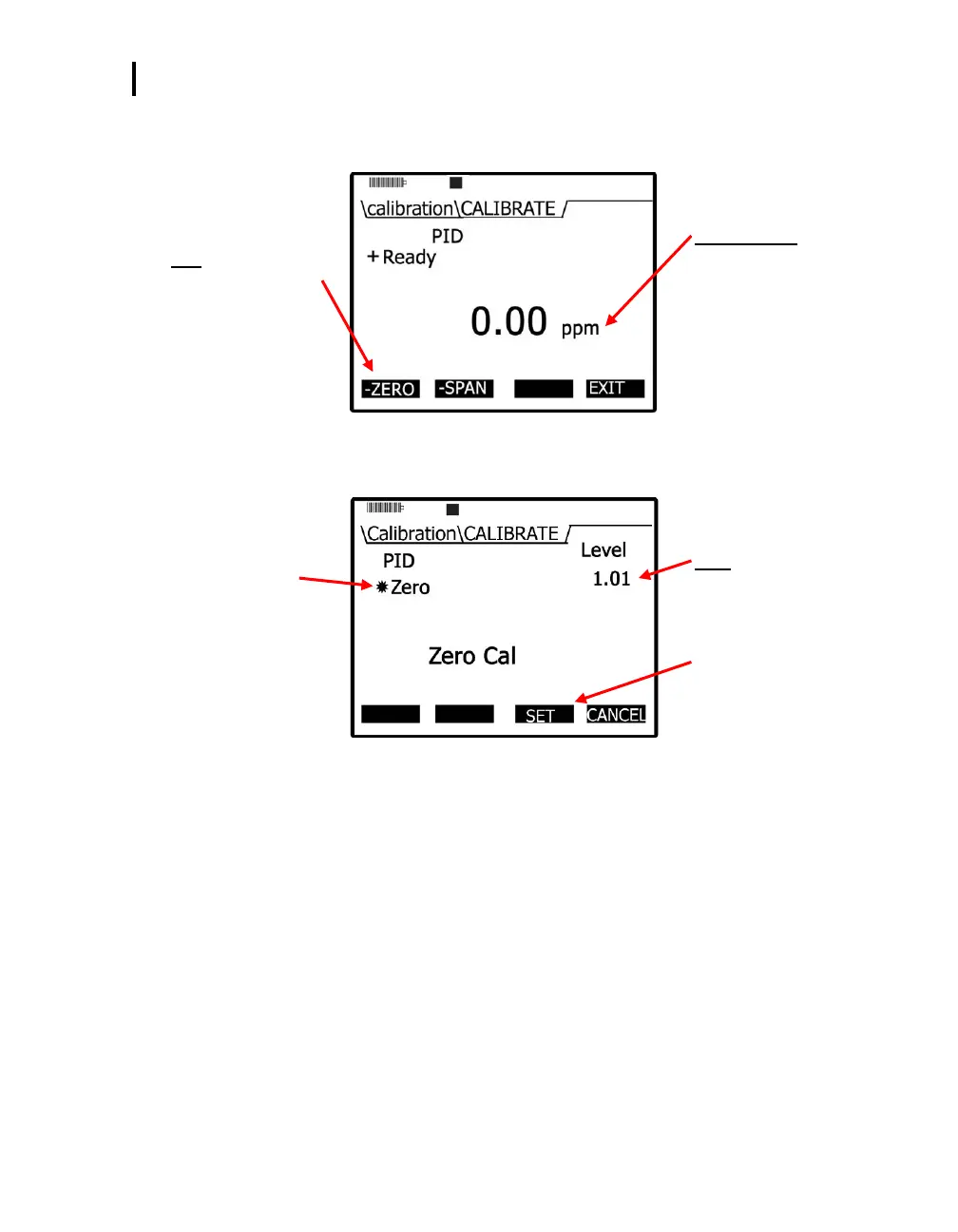

5. When the level has stabilized, press the Set soft key. (Or press Cancel soft key and then Retry

soft key to repeat this process.)

Flashing asterisk

indicates cal. mode.

Level

Allow to stabilize before

setting calibration point

Set soft key

Figure 4-28: Calibration mode screen

6. The PID/Pause screen will appear displaying the intended and actual calibration values. Press the

Save soft key. (Or press the Cancel soft key to repeat this process.)

To set the span cal, proceed to “PID – span calibration”.

7. To restore the factory calibration for the ppb sensor, select the HISTR soft key from the PID

calibration screen. Press the FACTRY soft key. This restores the ppb zero calibration value.

PID Span Calibration

Typically for PID 100 ppm, isobutylene is used for a span calibration when the VOCs are unknown or

apply the gas of interest if detecting a specific VOC for best results.

To measure a specific VOC with PID PPM sensor, you will want to use the relevant VOC for your

calibrated gas source. However, for PID PPB span calibration, it is recommended to use 10 ppm (or

10,000 ppb) isobutylene whether the gas of interest is known/unknown.

Loading...

Loading...