TITANUS MICRO·SENS

®

Commissioning

MS_A_07-en-e Data: 01/09 7 – 13

7.7.2 Carrying out function testing

After function tests are completed, the original settings must be restored.

So you should record these data (e.g. using the device protocol as

stored text files).

1. Close all the aspiration holes on the test pipe with some sticky tape.

The negative pressure generated by the TITANUS MICRO·SENS

®

must, after a short running time, be 80 Pa. For limited function test-

ing without the digital precision manometer, this step is omitted.

After the aspiration holes are closed, within 30 secs the device signals

the faults “Detection unit defective “and “Air flow too low (statistical

evaluation) “.

TITANUS

MICRO · SENS

®

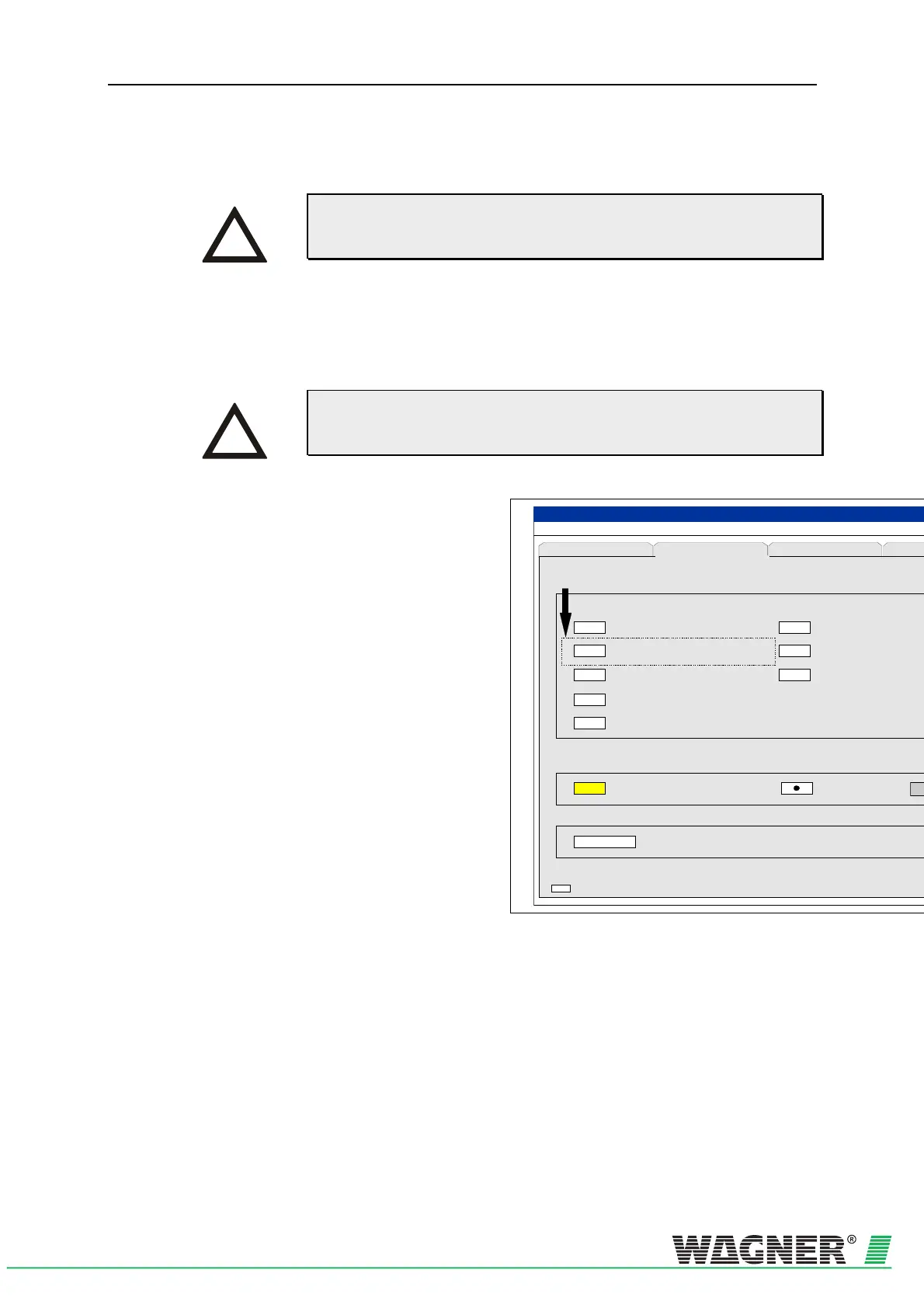

Air flow too high (statistic evaluation) Detector module dusty

Detector module fault

Program fault

Message is sent

?

Software Nr.

0000.00.001

File Record Settings Device-Selection

(Date Time)

Fault messagesStatus Settings RO

Reception

Serial No.

Air flow too low (statistic evaluation)

Air flow init aborted

Air flow has risen (dynamic evaluation)

Air flow has fallen (dynamic evaluation)

Message is memorized

2. Release the 4.6 mm and the 4.2 mm aspiration holes on the test

pipe again.

3. Now click on the lower “Set“ button in the “Settings“ screen and start

air flow initialising by pressing the “Initialise“ button.

The fault messages and displays must go out. The “Initialising

active“ field in the “Settings“ screen of the diagnosis tool flashes for

the duration of initialising.

INSTRUCTION

INSTRUCTION

Loading...

Loading...