Installation Pipe System TITANUS MICRO·SENS

®

6 – 14 Data: 01/09 MS_A_06-en-e

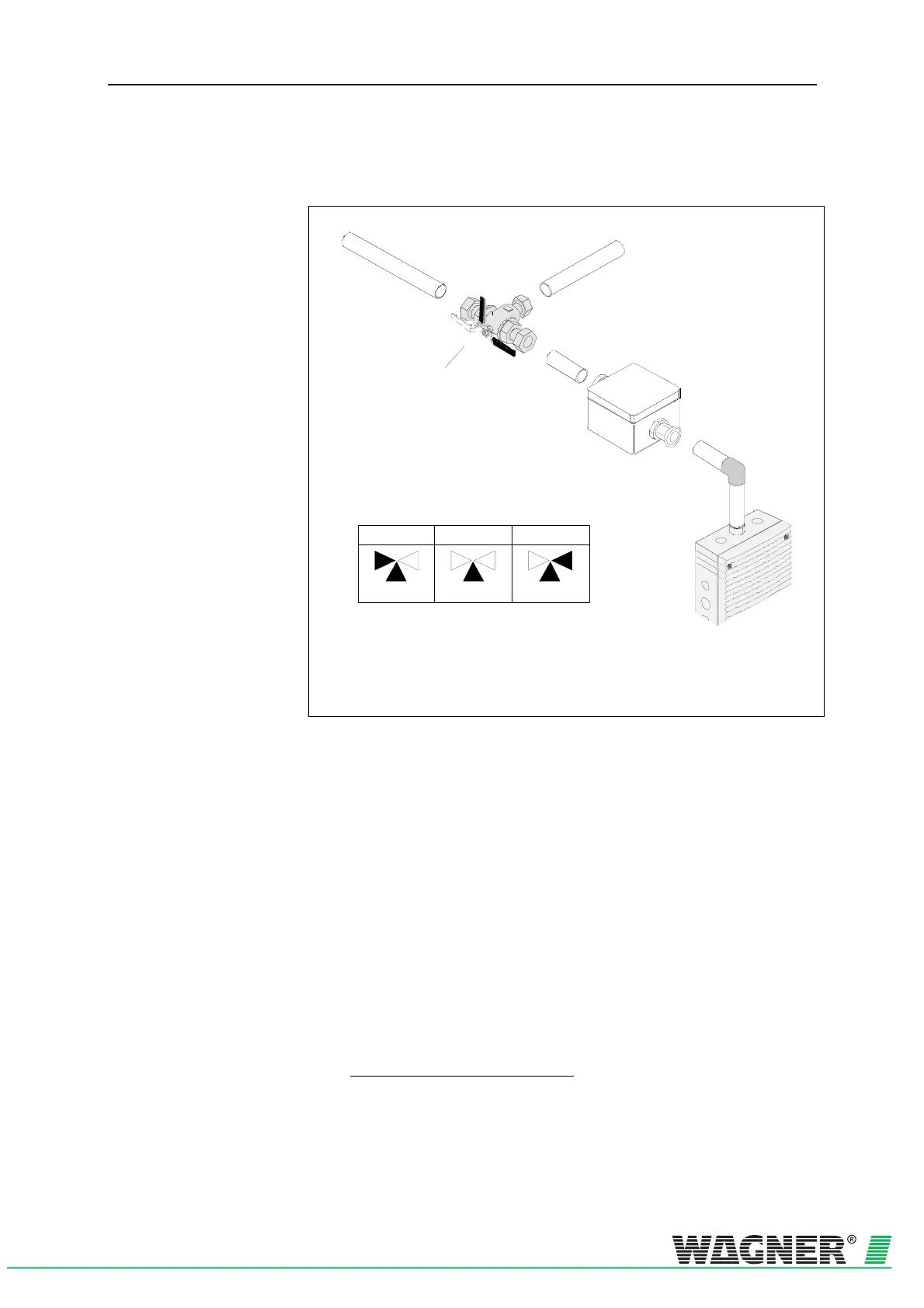

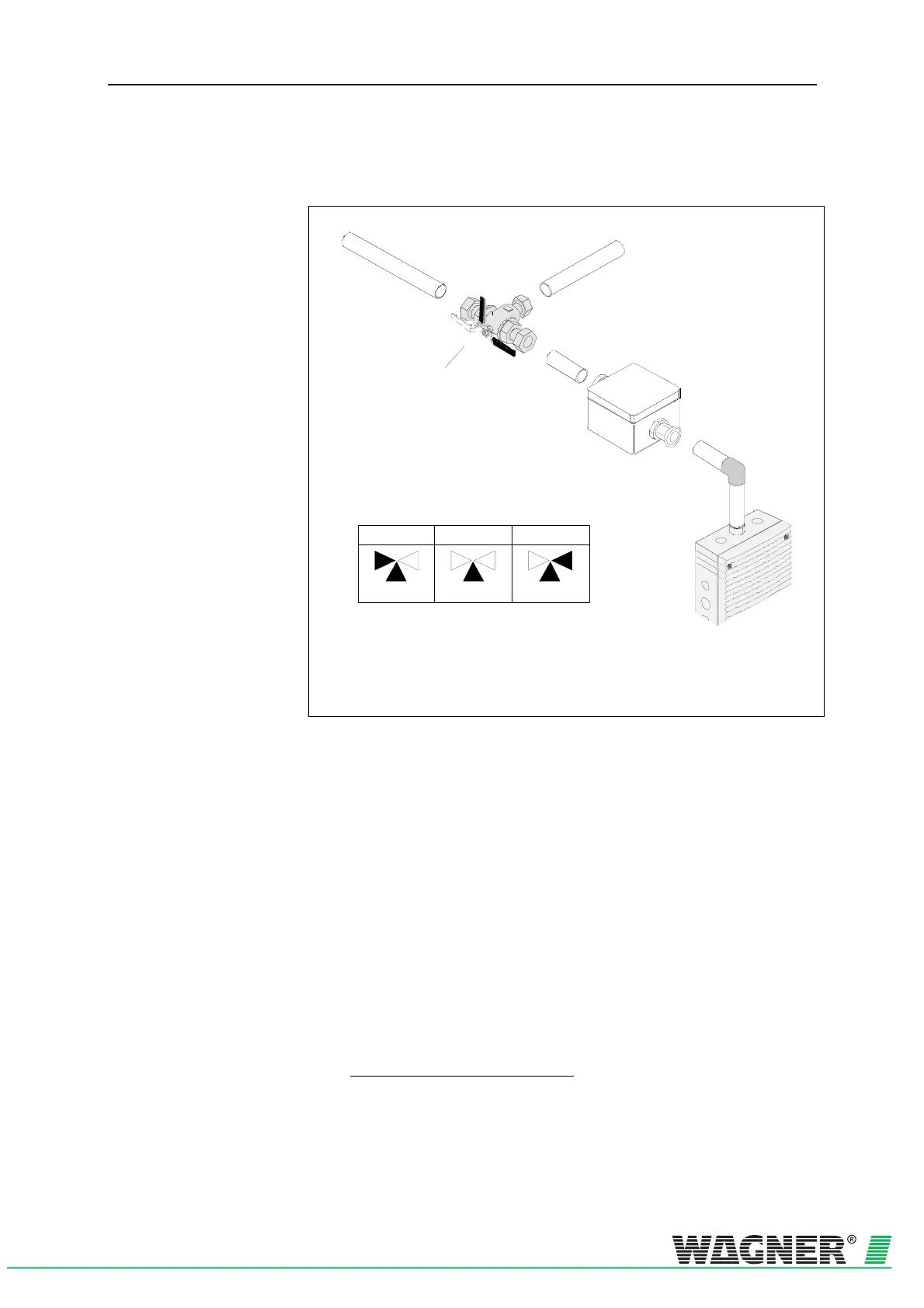

6.8 3-Way ball valve

TITANUS

MICRO

·

SENS

®

Air filter

(option)

C

o

n

n

e

c

t

o

r

p

i

p

e

s

y

s

t

e

m

C

o

m

p

r

e

s

s

e

d

a

i

r

c

o

n

n

e

c

t

o

r

Scheme of the ball valve:

Position 0° Position 90° Position 180°

C

o

n

n

e

c

t

o

r

a

i

r

s

a

m

p

l

i

n

g

s

m

o

k

e

d

e

t

e

c

t

i

o

n

s

y

s

t

e

m

3-way sleeve ball valve

(option)

type 3MKH

(max.16 bar)

1

8

0

°

0

°

9

0

°

A

AB

C

AB

C

AB

C

B

C

Fig. 6.11: Installation of 3-way ball valve

The ball valve is used for blowing through with compressed air (prefera-

bly) or pressed air

2

. Switching occurs between detection (position 0º) and

blow-through (position 180º). Connect the ball valve to the pipe system

via reducing screw-joints.

Connections During installation, ensure that the correct connections are made (see

diagram in fig. 6.11):

z connect the air sampling pipe system to C.

z connect TITANUS MICRO·SENS

®

to A or B and the com-

pressed/pressed air to the remaining connection.

2

Pressed air is compressed, non-purified surround air, containing humidity. Compressed air

is purified and de-humidified. If TITANUS TOP

⋅

SENS

®

and the pipe system are located in

areas below freezing, compressed air must be used for blow-through.

Loading...

Loading...