Maintenance TITANUS MICRO·SENS

®

8 – 6 Data: 01/09 MS_A_08-en-e

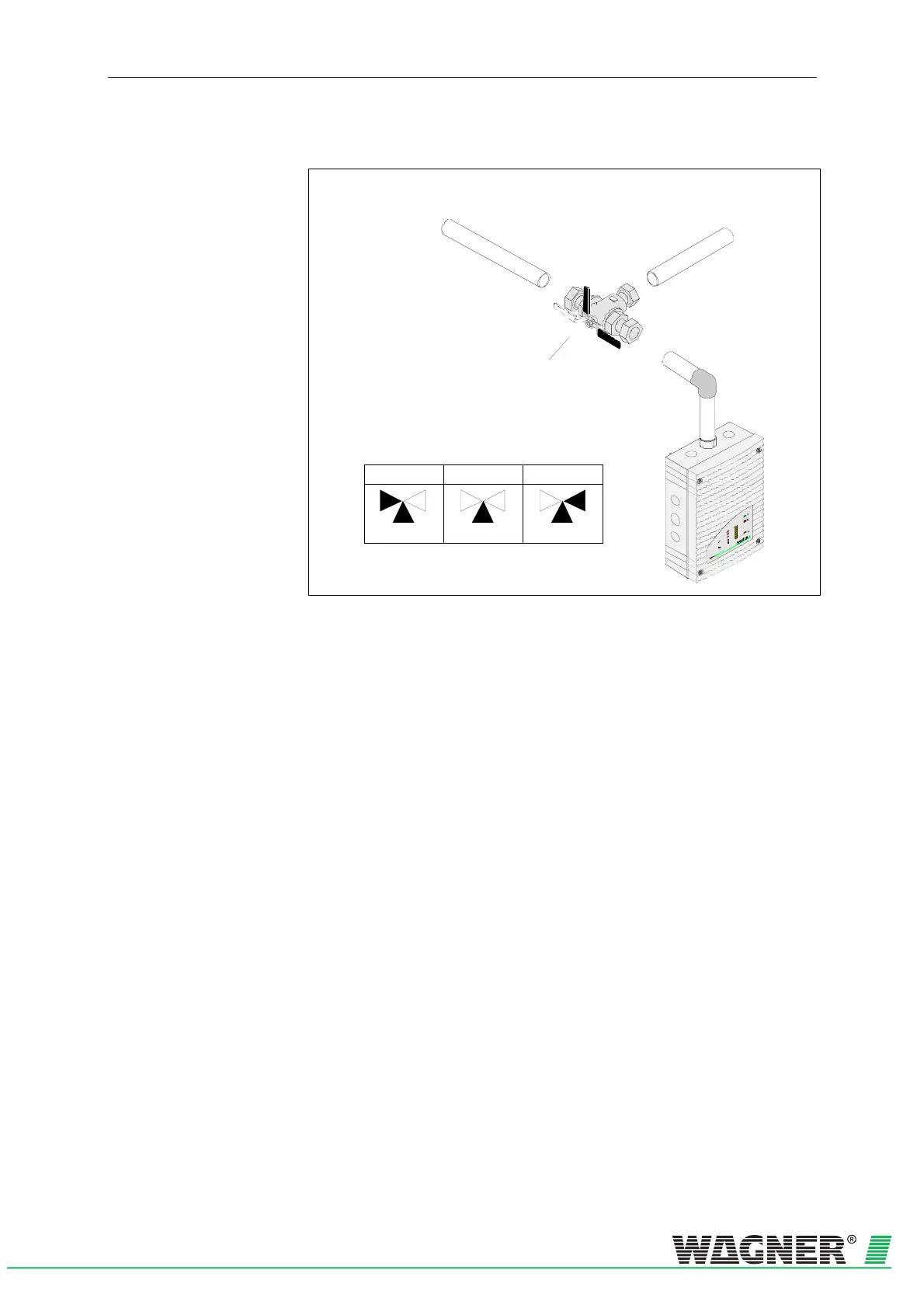

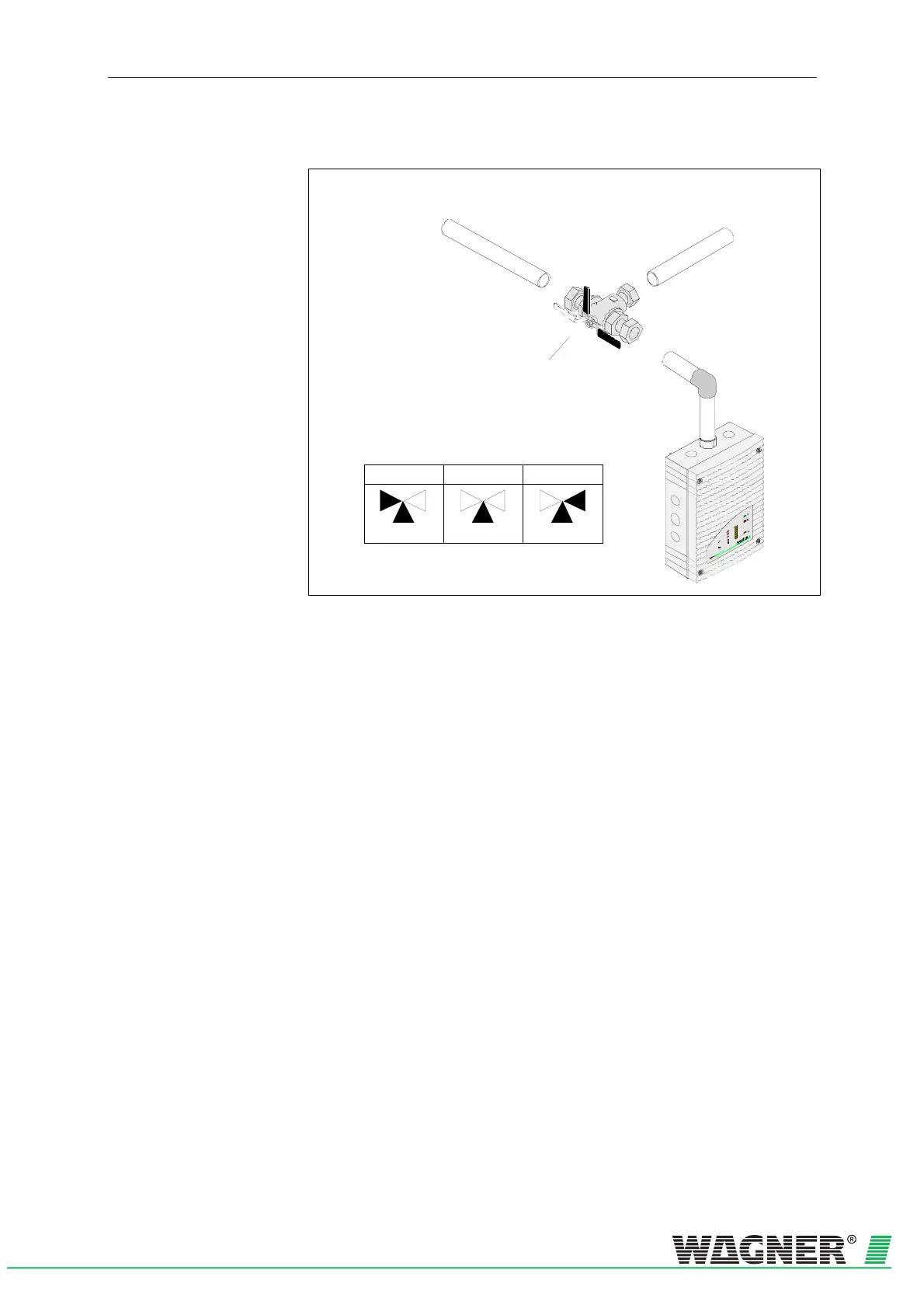

8.8 Pipe system blow through process

3-way muff ball valve

(max.16 bar)

1

8

0

°

0

°

9

0

°

A

B

C

TITANUS

MICRO

·

SENS

®

Scheme of the ball valve:

position 0° position 90° position 180°

AB

C

AB

C

AB

C

C

o

m

p

r

e

s

s

e

d

/

p

r

e

s

s

e

d

(

s

i

c

)

a

i

r

c

o

n

n

e

c

t

o

r

A

s

p

i

r

a

t

i

o

n

p

i

p

e

c

o

n

n

e

c

t

i

o

n

Fig. 8.7: Lever position on the ball valve

The pipe system manual blow through process should be conducted in

the following stages:

1. Connect the compressed air supply needed for free-blowing the pipe

system (compressor or mobile free-blow device) via the quick release

coupling muff to the 3-way muff ball valve on the pipe system to be

blown through.

2. Separate the pipe system to be blown through by the 3-way muff ball

valve from the corresponding device, by moving the ball valve lever

from the 0° operating position to the 180° position (see Fig. 8.7).

3. Blow the pipe system free manually for about 10 seconds.

4. Put the ball valve lever into the 90° position. In this position, the de-

vice cannot be connected either to the pipe system or the compressed

or pressed air supply connection. Wait about 20 seconds so that the

dust and dirt stirred up in the pipe system can settle and thus not be

aspirated via the air sampling smoke detection system.

5. Re-connect the free-blown pipe system to the corresponding device

within 10 seconds by setting the ball valve back to the 0

°

position.

Loading...

Loading...