TITANUS MICRO·SENS

®

Pipe Design

MS_A_04-en-e Data: 01/09 4 – 31

4.3.3 Design for Forced Air Flow

Monitoring air

conditioning ducts Air conditioning plants are divided into low-speed and high-speed plants

(see table below). The information given in this chapter applies only to

low-speed plants. There is insufficient information from experience with

high-speed plants. Where air conditioning ducts have flow speeds of

more than 10 m/s, therefore, smoke testing must be carried out for the

best reaction behaviour to be determined.

Low speed plants High speed plants

Flow speed maximum 6 to 10 m/s > 10 m/s

Duct cross-section large small

Differential pressures

along the flow direction

small large

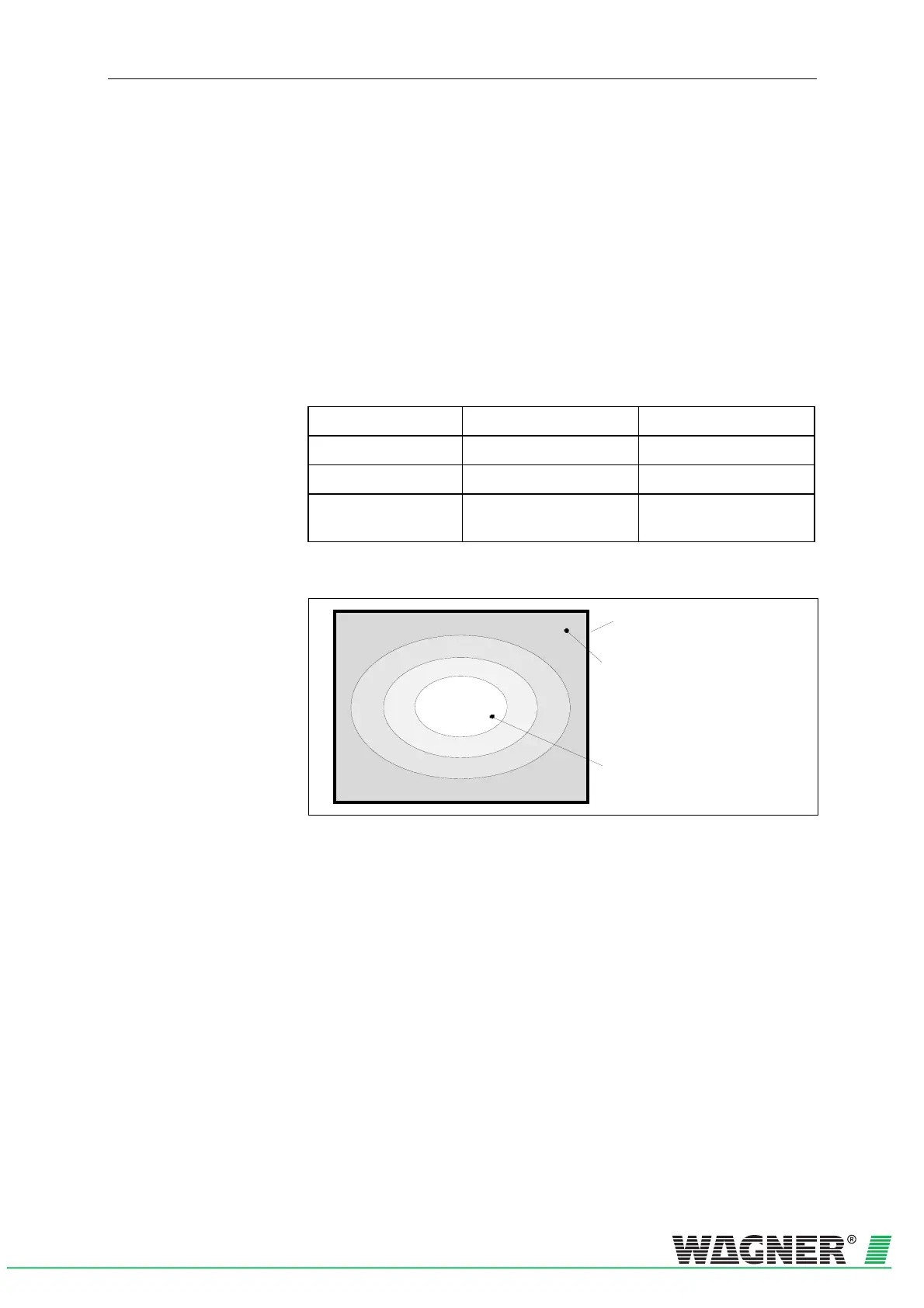

The speed distribution in an air conditioning duct looks as follows:

The largest air flow is t in the centre

of the cross section

Air conditioning duct

In the outer areas of the cross-section

surface area the air flow is lowest

v

1

v

2

v

3

v

4

Fig. 4.14: Speed distribution in an air conditioning duct with v

1

> v

2

> v

3

> v

4

Aspiration To achieve optimum detection results, the pipe system must be arranged

in the area v

1

to v

3

.

Location of the

pipe system To achieve the best location for constructing the pipe system, the ex-

haust duct should be as far as possible from sound dampers, air baffle

plates and kinks. The guideline figure for the distance from such “obsta-

cles” is at least 3 x the smallest duct diameter.

If it is absolutely essential to fit the pipe system directly behind baffle

plates, sound dampers or bends, the main speed areas must be

monitored (see Fig. 4.15/16).

Loading...

Loading...