TITANUS MICRO·SENS

®

Installation Pipe System

MS_A_06-en-e Data: 01/09 6 – 1

6 Installation Pipe System

The pipes and fittings used for the pipe system must always meet re-

quirements for Class 1131 in accordance with EN 61386-1, 2004.

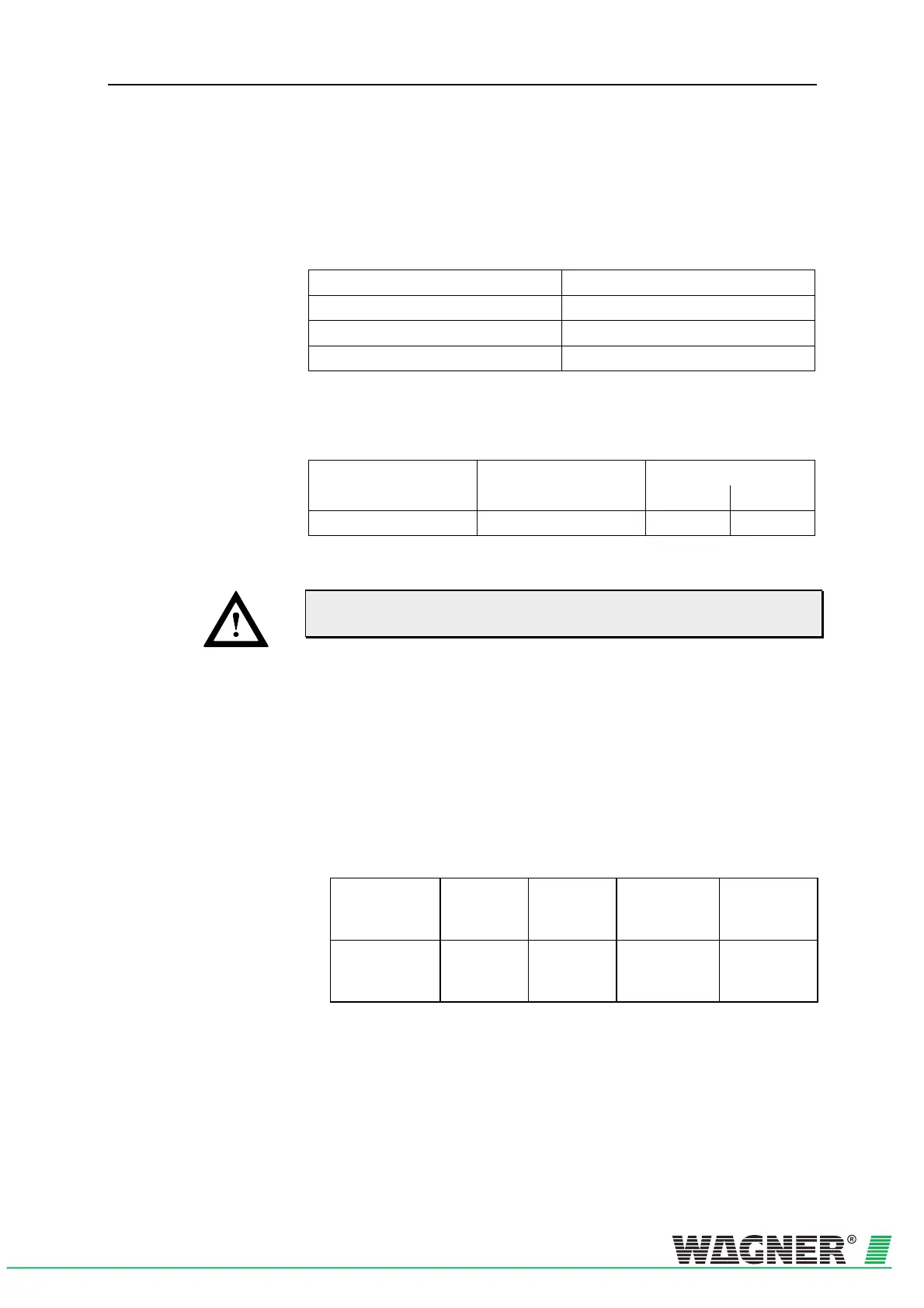

Class 1131 puts the following requirements on the pipe system used:

characteristics severity code

compression resistance 125 N

impingement resistance 0,5 kg, drop height at 100 mm

temperature range -15 °C to +60 °C

In principle, the following pipes as well as the related fittings are to be

used in configuring the pipe system:

external diameter internal diameter

ABS PVC

air sampling pipe 25 mm 21,4 mm 21,2 mm

Take note of the temperature range specified in the “Technical data”

chapter under “3.3 Pipe system” when configuring the pipe system.

installation instructions The pipe system is to be constructed to suit the project and in compliance

with the design guidelines (see Chapter 4 "Design").

1. Shorten the pipes using a pipe cutter or a metal saw. De-burr the inter-

faces and then clean them of any swarf.

2. Clean the adhesion points of dirt and grease before using the

adhesive, using the prescribed cleaner. Then stick the pipe junction

pieces to the associated fittings so that they are air-tight.

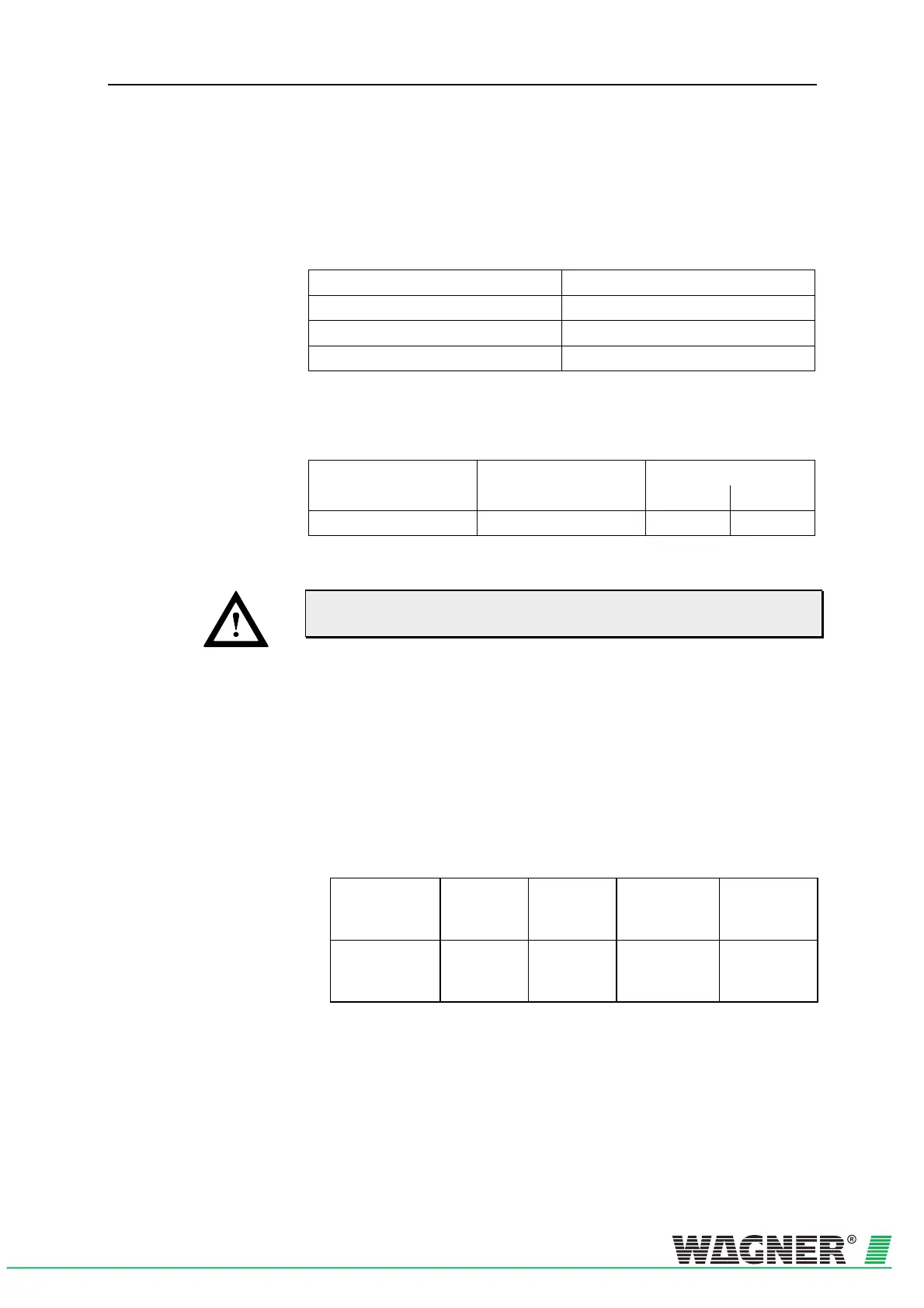

Air Sampling

Pipe, halogen-

free

Air Sam-

pling Pipe

(PVC)

Cleaning

Agent

Adhesive Pipe Cutter

ABSR-2518, R-2519,

Tangit clea-

ner

Tangit

adhesive

Pipe shears

or cutter 38

mm

ATTENTION

Loading...

Loading...