Chapter 10 Troubleshooting 40058725 BTA Alpha HSM

Version: 12.19.17 Page 103 of 112 GB

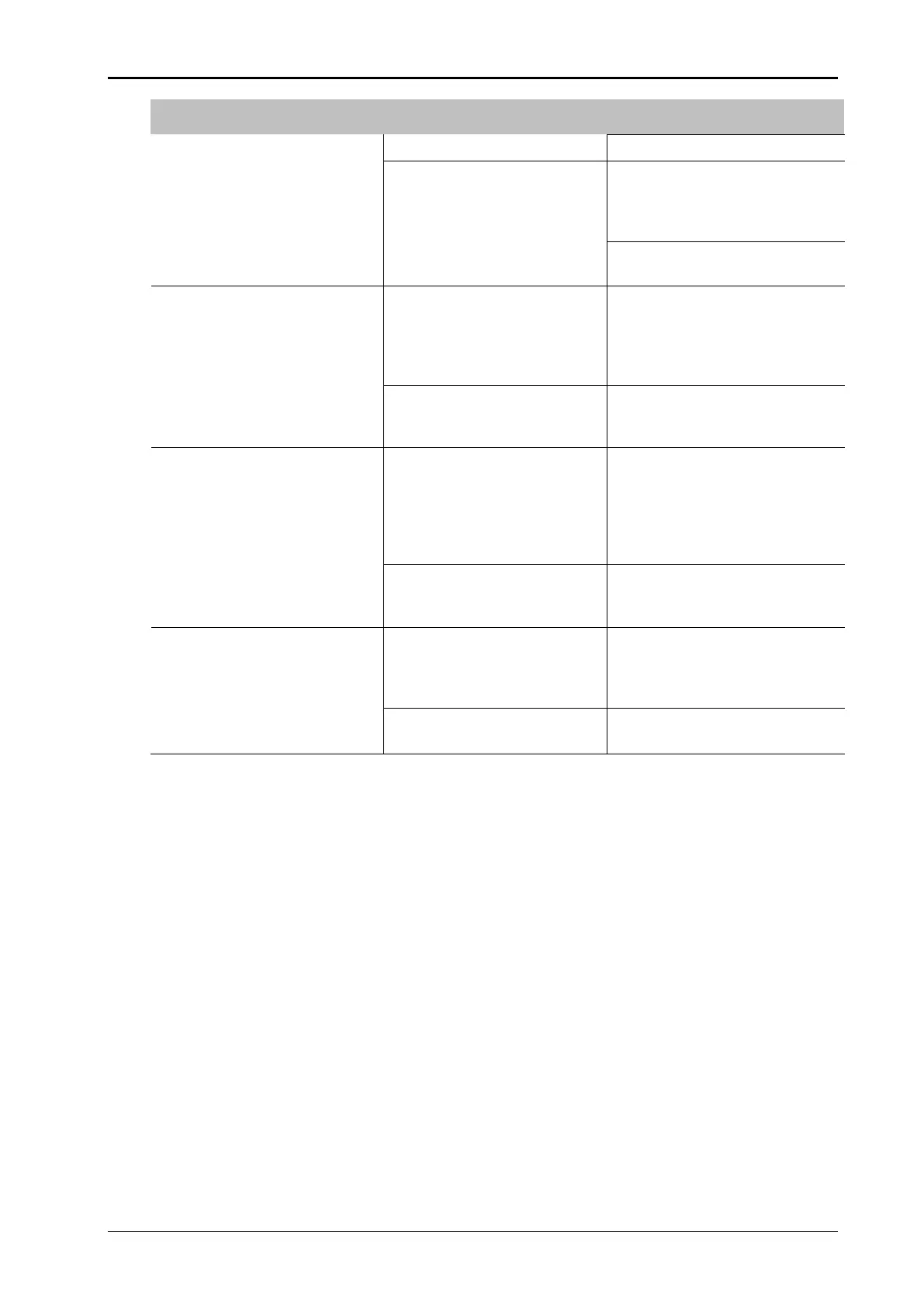

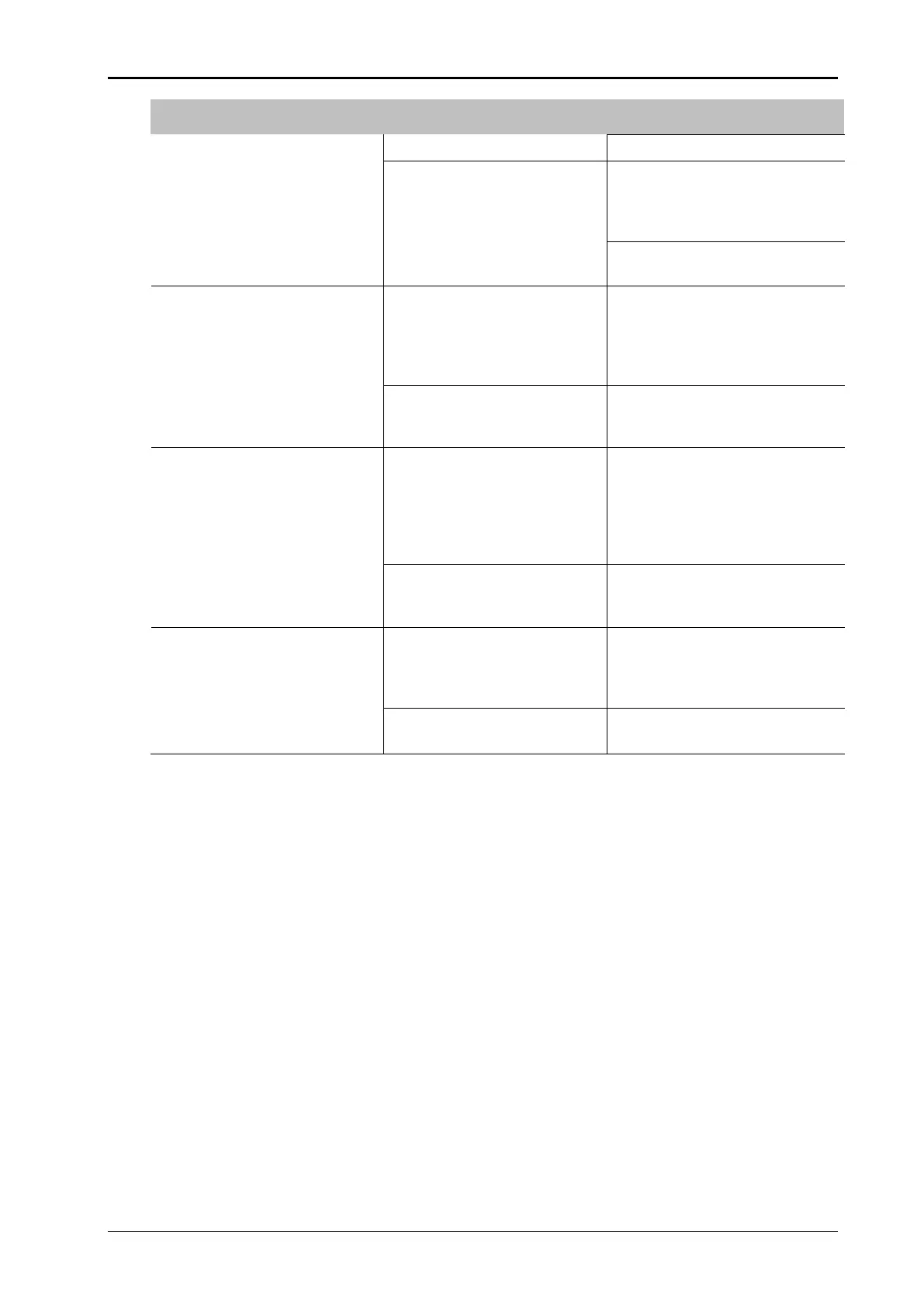

Web brake set too stiffly.

With a mechanical label

stop scanning:

Label is not correctly recog-

nised.

Newly insert the label liner as

required or check the position

of the label sensor.

Remove accumulations of ad-

hesive on the scanning roller.

Labels run through without

stopping or the positioning of

the label on the peeler plate is

not uniform.

Replace the label sensor.

LED at the receiver of the

label sensor is permanently

on.

The sensitivity setting must be

checked.

The desired product cycle rate

is not reached by the dis-

penser.

The cycle speed of the con-

veyor system is beyond the

specification.

Check the belt speed and the

product distance, compare the

values with the technical data

taking into account the label

lengths used. If possible, reduce

the cycle rate.

Incorrect settings of the la-

beler, system cycle times too

great

Request a service technician

through the hotline (see page

9).

The applicator starts to label

without any apparent reason.

Sensors for the product de-

tection are loose, vibrate, or

are influenced by reflections

from the product surface

Check the sensor settings or

request a service technician

through the hotline (see page

9).

Check all connections on the

labeler.

Loading...

Loading...