Chapter 6 Installation and connection 40058725 BTA Alpha HSM

Version: 12.19.17 Page 46 of 112 GB

End of roll warning connection (low label)

Through the end of roll pre-warning an upcoming label roll change can be indicated at an

early stage. Depending on the module version, the end of roll pre-warning function is

available in two versions.

External version

An optional reflection light scanner on the unwinder arm scans the label roll. Adjustment of

the sensor is not necessary if the option is factory installed. The reflection sensor is con-

nected via an M12 4-pin plug to the optional flange socket (see page 38).

As soon as the label roll falls below a certain diameter, the warning message "Low la-

bel reached" appears in the display and a signal is transmitted. In conjunction with the

3-colour signal lamp, the signal is indicated by the yellow light.

The labeler will remain operational until the pre-programmed remaining label length has

been used up. Then the labeler will go into malfunction mode and stop, and the error

message "Web end reached“ will appear in the display.

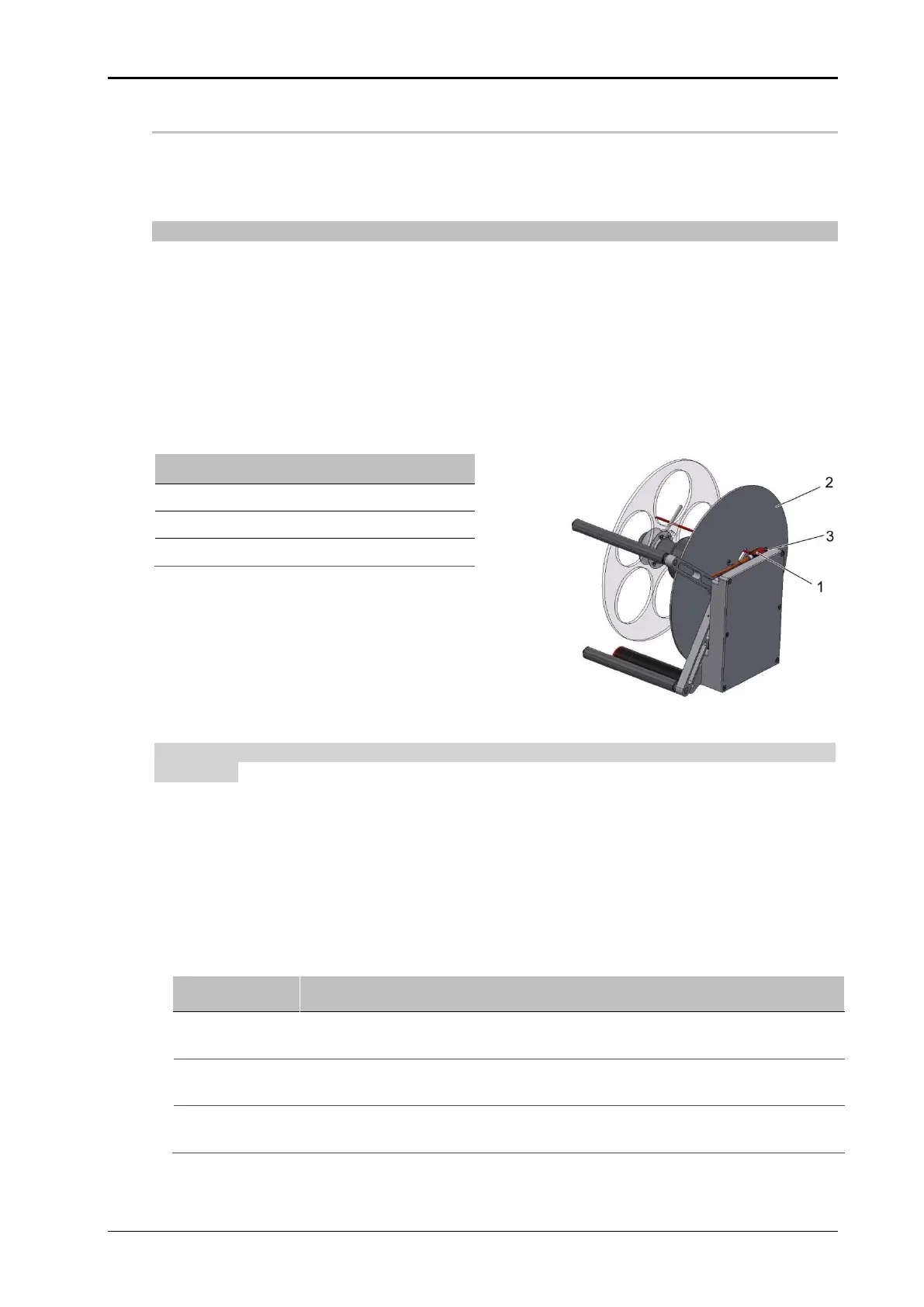

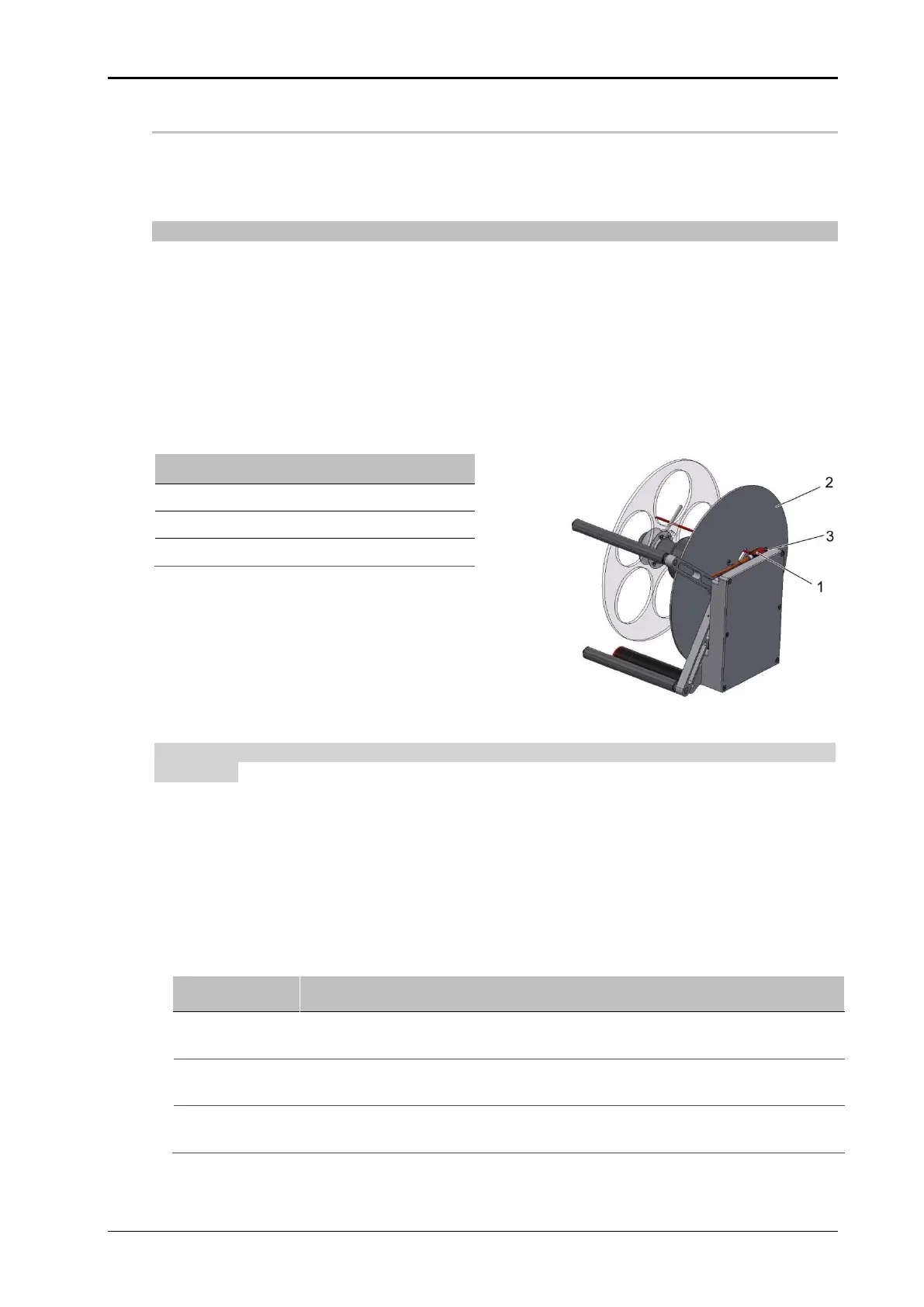

Fig. 6-12: End of roll warning external

Adjustment of the sensor is normally not required when the option has been installed by

the factory.

Prerequisites

Label web roll with the desired, residual amount that should trigger pre-warning.

No product supply.

Labeling machine is ready for operation.

Instruction

How to adjust the low label warning.

Place the remaining label roll, for which a warning message is to be dis-

played, on the unwinder reel.

Turn the disc (pos. 2, Fig. 6-12) with the groove on the sensor (pos. 1, Fig.

6-12).

Turn the small adjusting screw (pos. 3, Fig. 6-12) at the front side of the

sensor in the clockwise direction until the status LED lights up.

Loading...

Loading...