Chapter 8 Operation 40058725 BTA Alpha HSM

Version: 12.19.17 Page 78 of 112 GB

Temporary setting options

Temporary changes to the parameters are only used to correct the

settings while the dispenser is running. Permanent storage of the

parameters determined must manually be performed on the "Con-

figuration" menu level.

The temporary adjustment options can be reached from the "Manual advance" menu by

turning the adjustment button.

Press the adjustment button for a long time (>3 seconds) to exit the temporary settings

options.

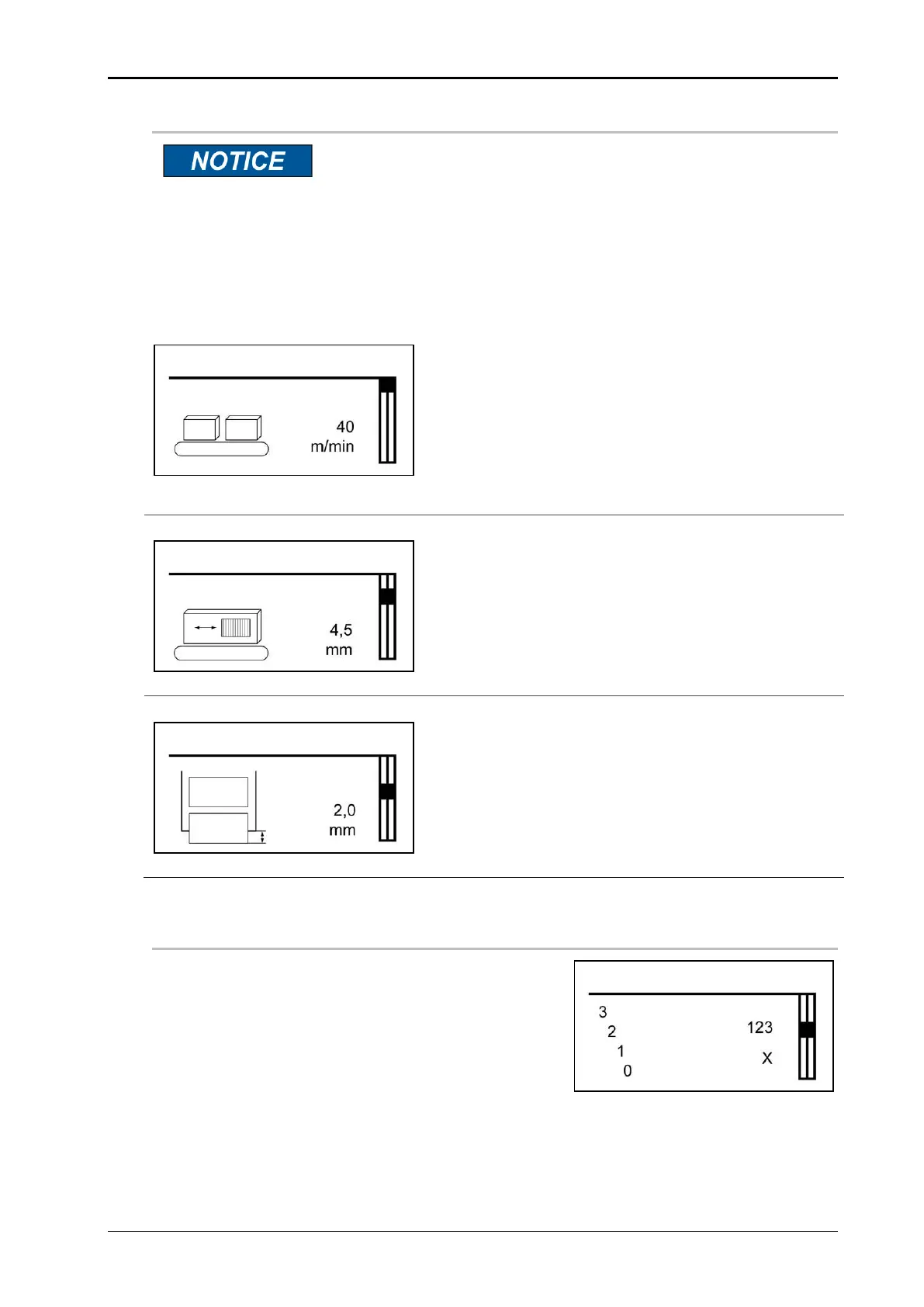

Fig. 8-16: Temporary speed

Temporary speed

Speed at which the label is dispensed. The feed rate

of the labels can be set to a fixed value.

If the speed is to be automatically adapted to the

conveyor belt technology, a rotary encoder must be

connected. The labeler speed and the product speed

must be the same to achieve optimal results. The

adjustment range is 1.0 - 70.0 m/min.

Fig. 8-17: Temporary application delay

Temporary application delay

This parameter is used to delay the labeling process,

i.e. by how many millimeters the label is applied off-

set to the product from the trigger signal onward. The

adjustment range is 0 – 999.9 mm.

Fig. 8-18: Temporary application position

Temporary application position

The label position is a value that ensures that the

label stops flush at the peel bar. The value can here

be adjusted. The adjustment range is -50.0 to 200.0

mm.

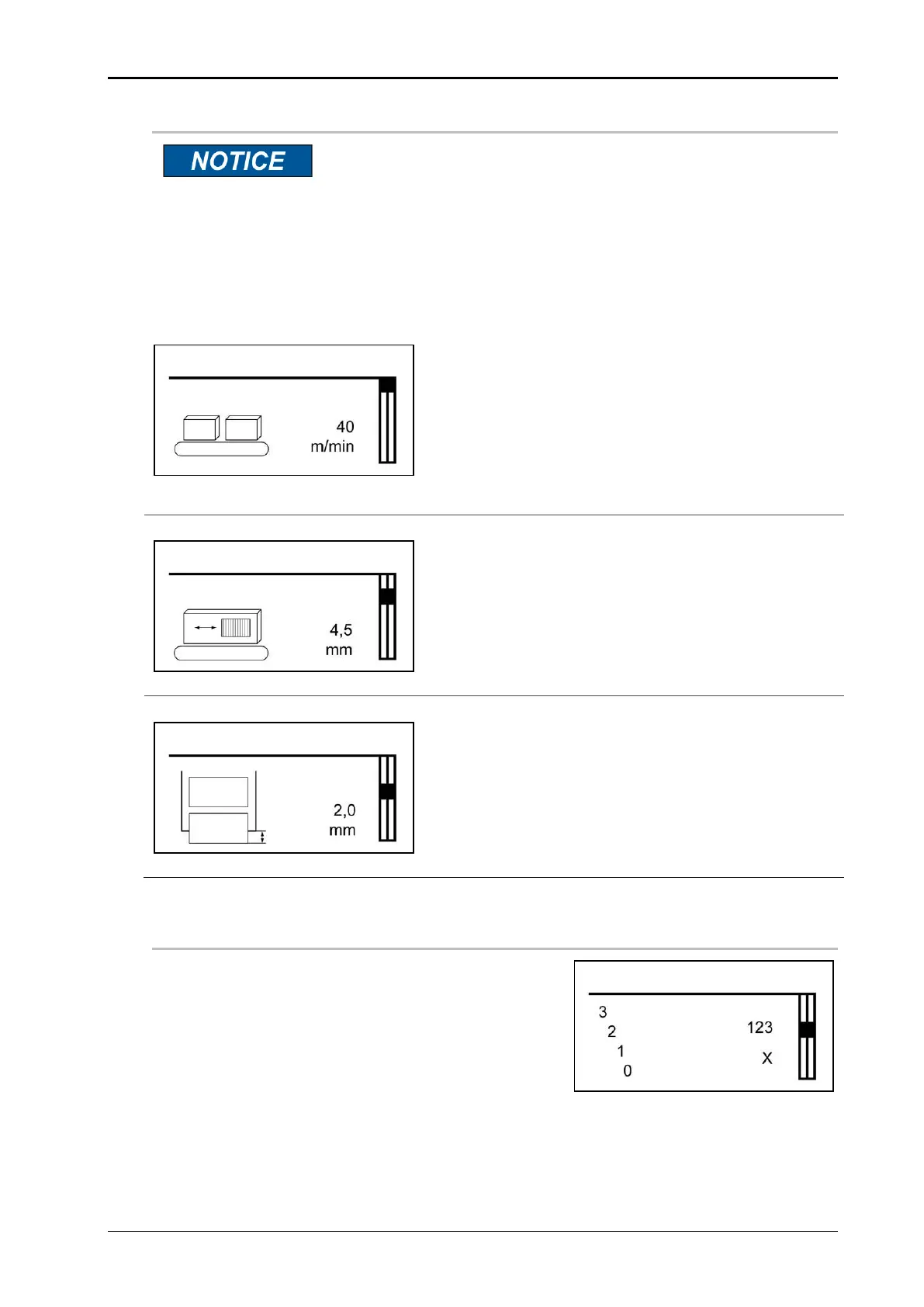

“Countdown“ (Set Count Down)

Here, you can activate the "Countdown" function,

i.e. the value set is counted down in every dispens-

ing cycle during the labeling mode. The counter

value corresponds to the remaining application

cycles. The labeler automatically stops and gener-

ates a warning message when the end value "000

0" is reached. The adjustment range is 0-99999.

"" results in acceptance of the "Countdown" val-

ue, "X" results in termination of the input.

Temporary label position.

Loading...

Loading...