Installation: Commissioning

Issue 2

7

Part No. 306-0430-102

28

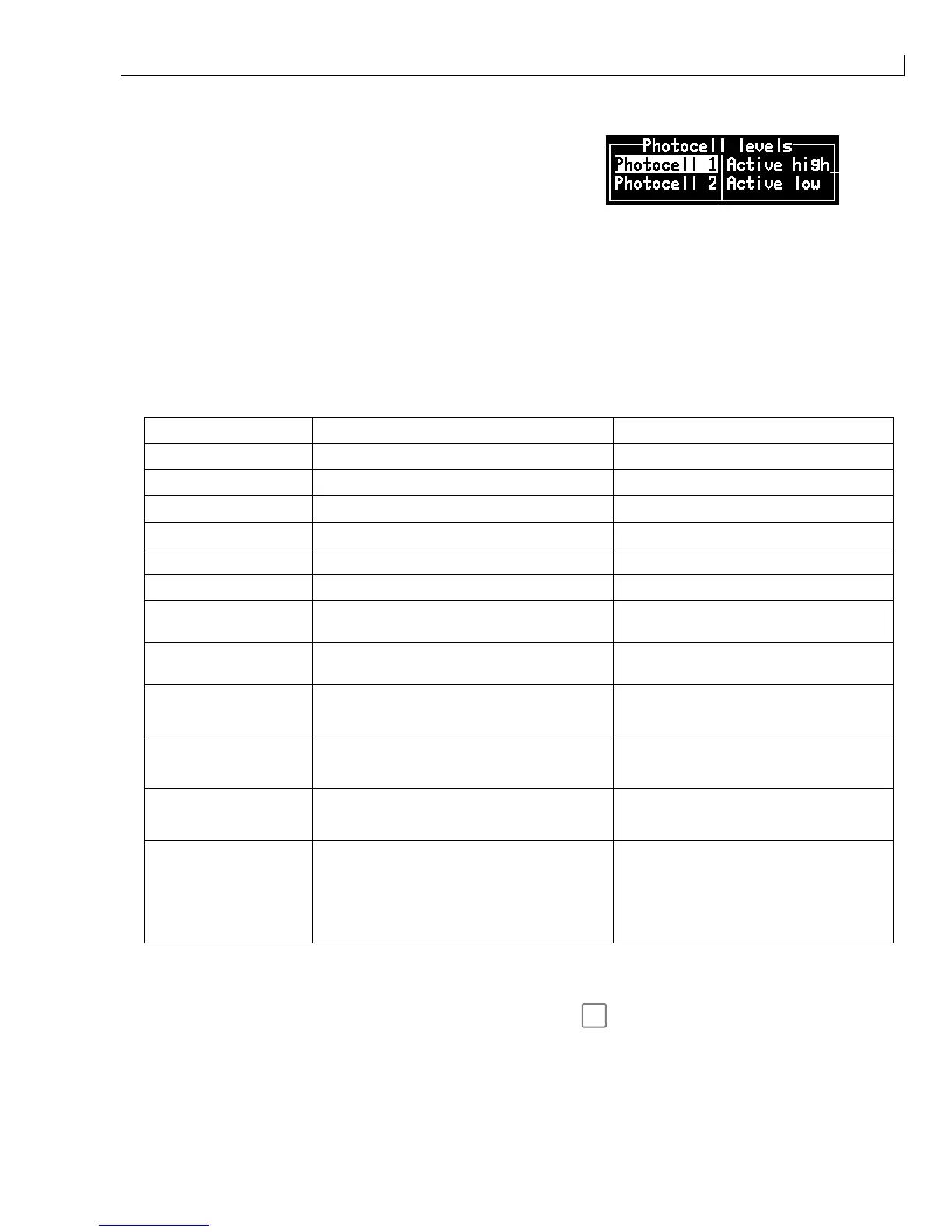

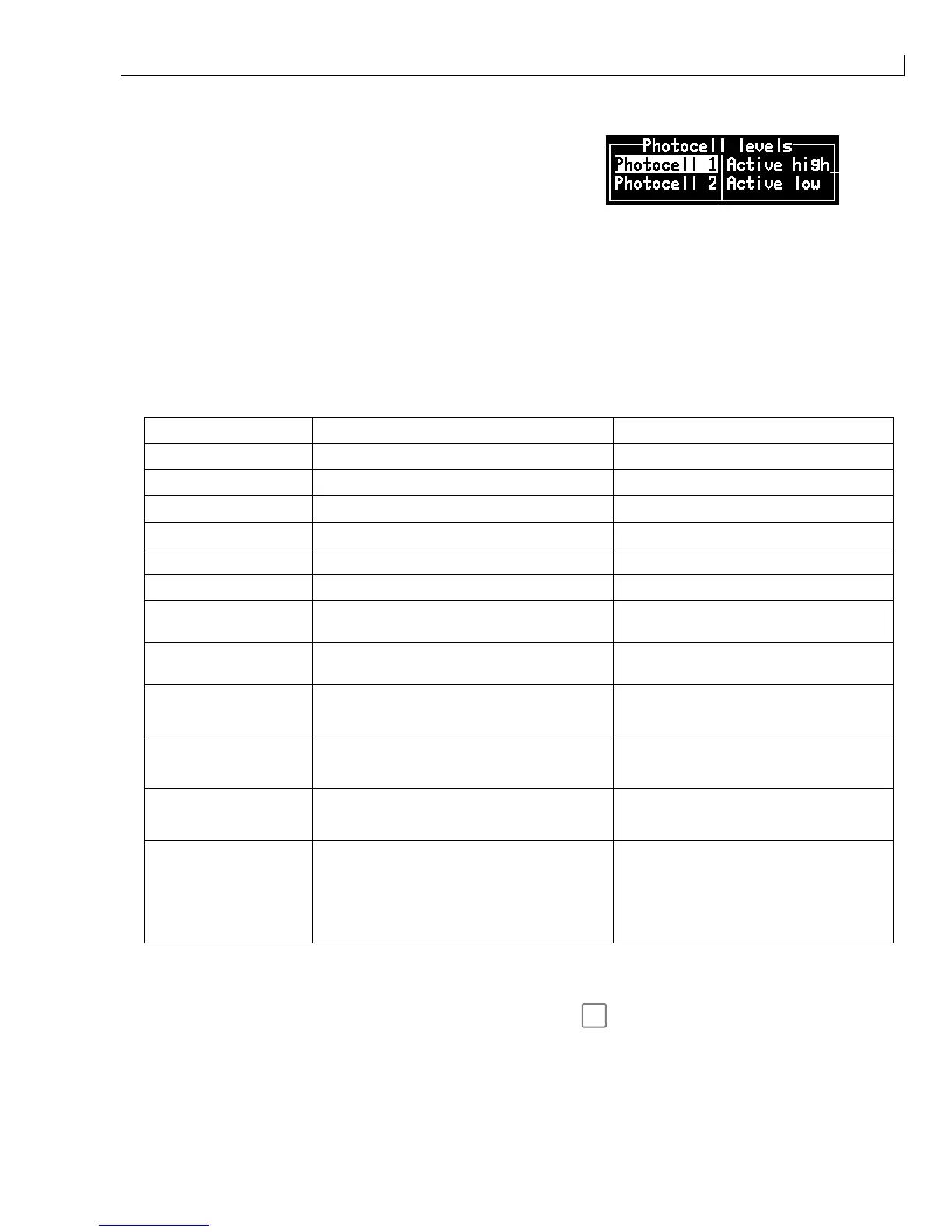

From the

Configure

menu, select

Photocell Levels

and set

the state of the

photocell 1 level

to

Active high

or

Active Low

as required.

29

The printer should now be printing continuously. Let the printer complete a minimum of 250 000 prints. Use

the counter to monitor the number of messages printed. Monitor the printer to ensure that the system

functions correctly.

30

At regular intervals access the

Calibrate

menu and select the Diagnostics Screen. Monitor the machine

parameters and check that they remain stable. Typical Diagnostics Screen values are shown in the table

below.

Note: The values provided are typical. The exact figures will vary slightly for each machine depending

on the model, ink type and ambient conditions.

Machine Parameter Typical Value (see Note above) Dependancy

Ink Pressure 32 Ink type, Pressure set value.

Cabinet Temperature 35 Ambient temperature.

Viscosity Set Point 29 Ink type, Ambient temperature.

Phase Angle Any value (must be stable) Correct Jet Break-up.

Ink Temperature 25 Ambient temperature

Head Temperature 25-35 Ink type, heater set point.

Viscosity Actual 29 Indicated value

±

1 compared to Viscosity

Set Point = correct viscosity.

Phase Profile 08-09 (Ideal) Phase charge, charge value,

Phase pick-up position

Ink (Reservoir Tank)

J

Covered

F

Low

Level Detect covered – OK

Level Detect uncovered – LOW

Sol (Top-up Reservoir)

J

Covered

F

Low

Level Detect covered – OK

Level Detect uncovered – LOW or EMPTY

VMS

F

J

Full

F

F

J

Filling

J

J

Emptying

F

Empty

VMS chamber Sequence

Mix

F

F

F

J

High

F

F

J

On

J

F

Empty

J

Low

J

J

MIXER TANK CONDITION

High – Tank level too High

On – Tank level OK

Low – Tank level too Low

31

After 250 000 prints have been satisfactorily completed, press

f1

and ensure that the printer performs a

clean shutdown.

Note: If the machine does not provide an adequate clean start-up or shutdown during these

procedures, it is possible that air may have become trapped in the flush pump and flush

pipework.

Loading...

Loading...