System Calibration and Test: Ink Viscosity Measurement

Issue 2

41

Part No. 306-0430-102

Ink Viscosity Measurement

Note: Before testing viscosity, ensure that the printer is at normal operating temperature.

1

Set up the syringe viscometer over a beaker that contains a thermometer.

2

Using the large syringe supplied, draw out at least 60 ml of ink from the mixer reservoir.

3

Cover the viscometer syringe nozzle, using a gloved finger, and fill until the ink is level with the top of the

syringe.

4

Using a stopwatch, time the flow of ink through the viscometer from the time when the finger is removed

until the last drop of ink falls from the nozzle.

5

Make a note of the time, and also the temperature indicated on the thermometer.

6

Apply the temperature compensation factor (given on the graph supplied with the viscometer) to the time

recorded and trace a reading on the main Time versus Viscosity graph (supplied with the viscometer).

Caution – Incorrect Measurement

If the temperature compensation factor is not used, the end result could be incorrect

by as much as 40%.

7

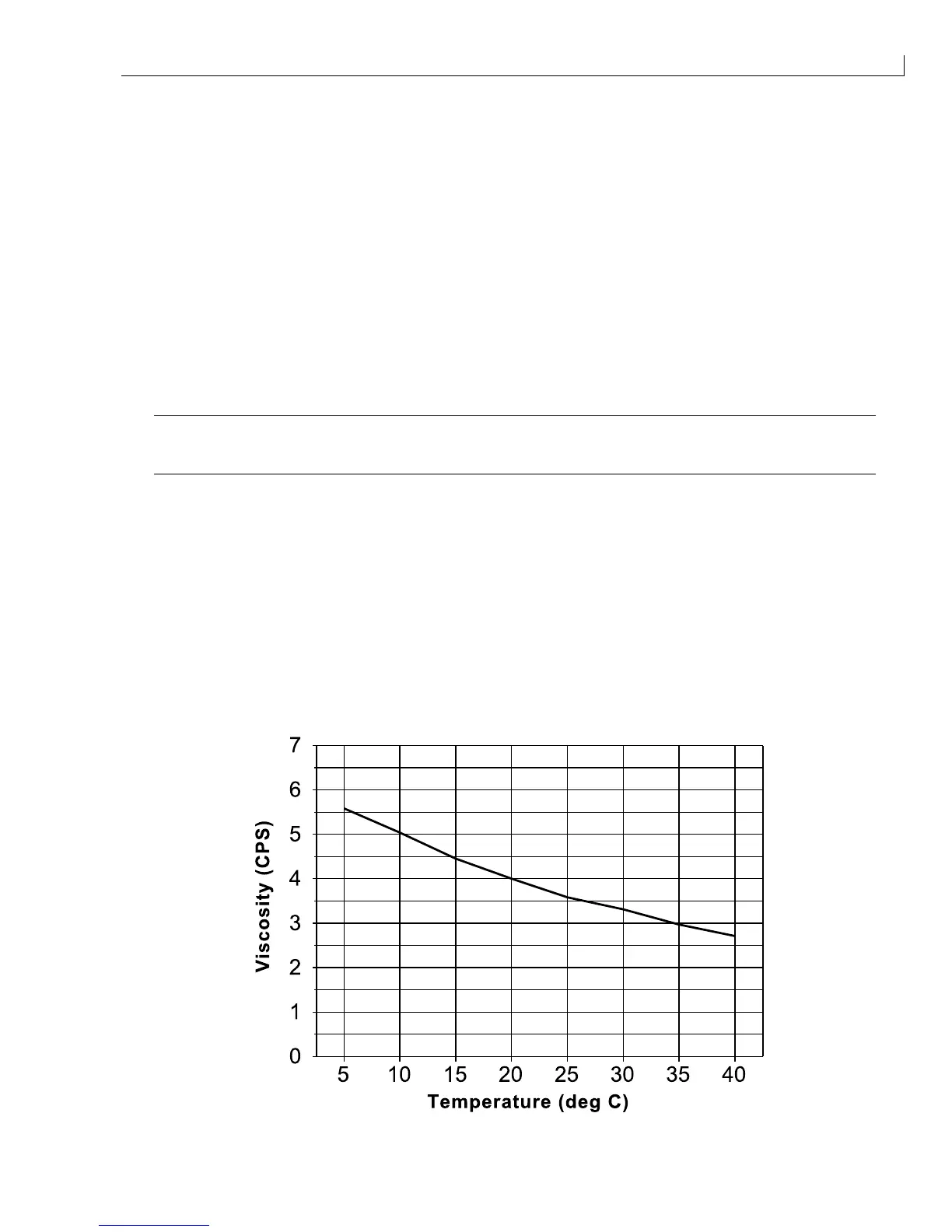

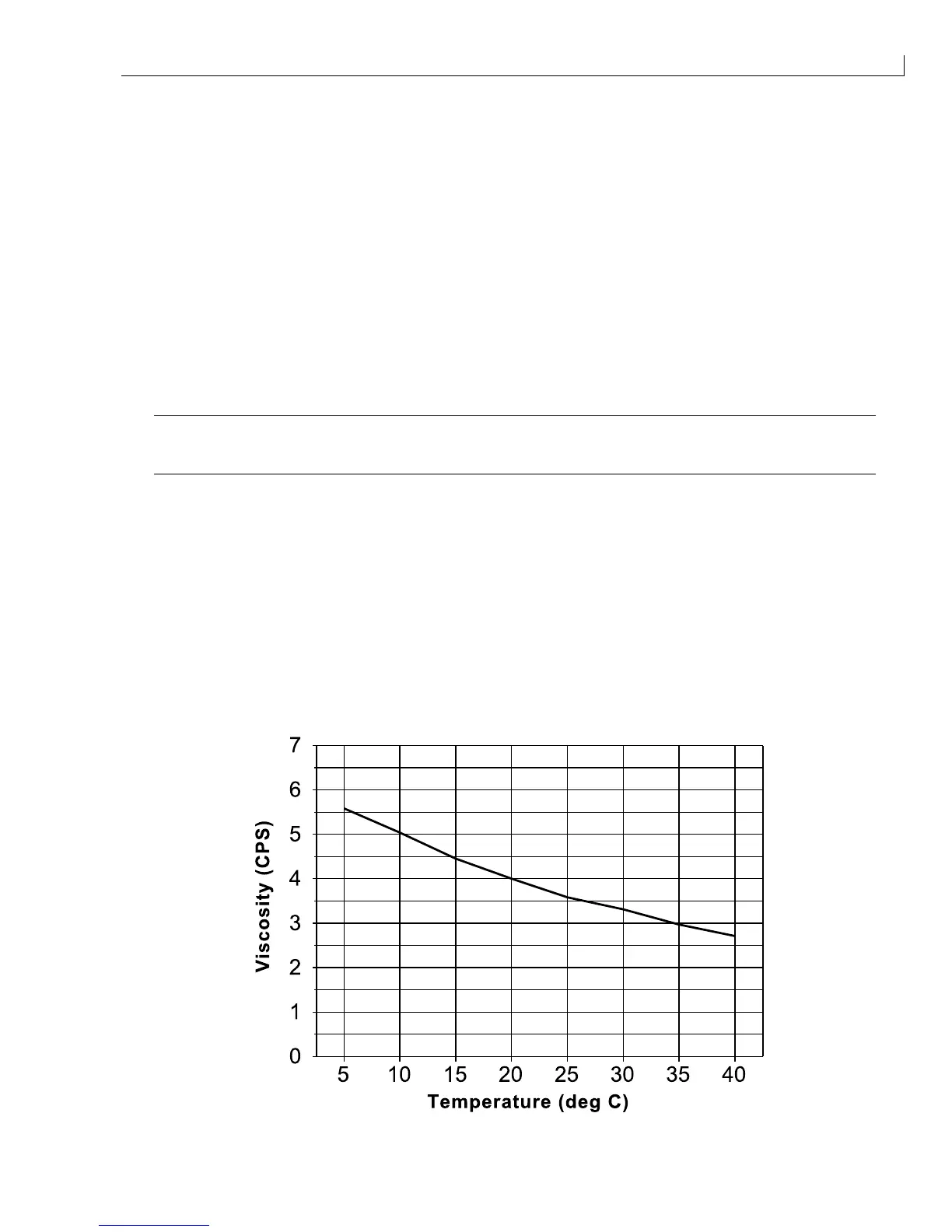

Refer to the temperature versus viscosity graph that relates to the ink being used. The graphs are listed in

the next section.

8

Relate the temperature noted at step

5

to the horizontal axis of the graph. Use the graph to calculate the

optimum viscosity (vertical axis) for the ink.

9

Compare the measured viscosity to the optimum viscosity to determine whether the viscosity is high or low.

Temperature/Viscosity Graphs

This section contains graphs of temperature versus viscosity for the range of inks used in the 400 Series

printers.

CIJ MK 390ID Black

Loading...

Loading...